Shoe material for luminous EVA shoe sole and preparation method

A technology of shoe material and luminous powder, applied in soles, footwear, applications, etc., can solve problems such as hidden dangers of children's foot development, broken and damaged light strips, loss of luminous function, etc., and achieves good market prospects, environmental protection of materials, and weight. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The invention provides a shoe material with a luminous EVA sole, comprising the following components in parts by weight:

[0041] 50 parts of ethylene-vinyl acetate copolymer resin; 8 parts of ethylene-octene block copolymer; 10 parts of polyolefin elastomer; 2 parts of EPDM rubber; 10 parts of luminous powder; 0.6 parts of bridging agent; 0.2 parts of lubricant 2 parts of flow agent; 5-10 parts of filler; 5 parts of anti-wear agent; 0.2 parts of catalyst; 3 parts of foaming agent.

[0042] The luminous powder includes aluminate luminescent rare earth; the foaming agent is azodicarbonamide ADC foaming agent.

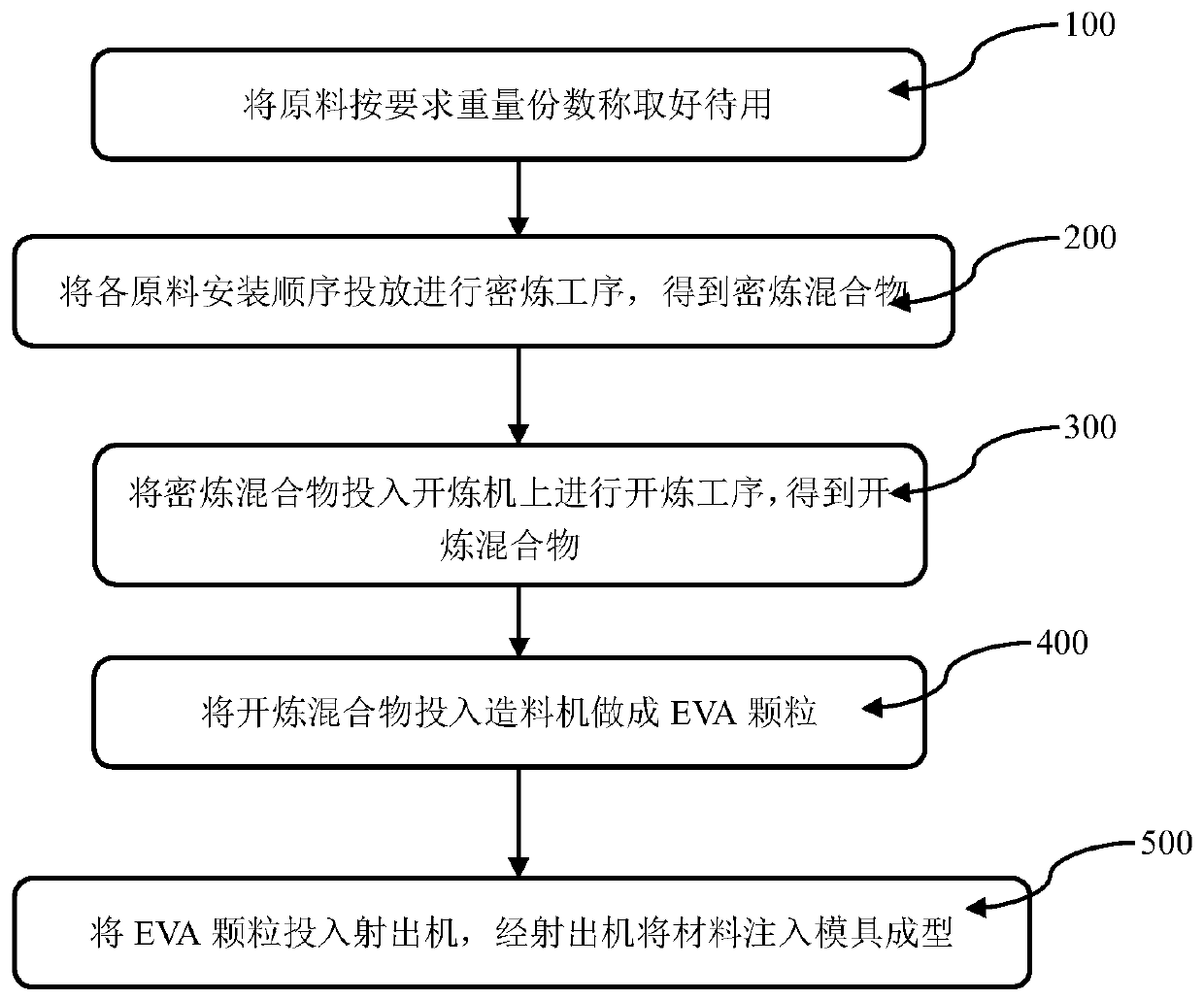

[0043] like figure 1 Shown, the shoe material preparation method of this luminous EVA sole comprises the steps:

[0044] Step 100, the raw materials are weighed according to the components in Example 1 and ready for use;

[0045] Step 200, putting each raw material in order to carry out the banburying process to obtain the banbury mixture;

[0046] Described b...

Embodiment 2

[0061] The invention provides a shoe material with a luminous EVA sole, comprising the following components in parts by weight:

[0062] 60 parts of ethylene-vinyl acetate copolymer resin; 10 parts of ethylene-octene block copolymer; 20 parts of polyolefin elastomer; 6 parts of EPDM rubber; 15 parts of luminous powder; 0.8 parts of bridging agent; 0.35 parts of lubricant 3.5 parts of flow agent; 7 parts of filler; 6 parts of anti-wear agent; 0.35 parts of catalyst; 4.5 parts of foaming agent.

[0063] The luminous powder includes aluminate luminescent rare earth; the foaming agent is azodicarbonamide ADC foaming agent.

[0064] like figure 1 Shown, the shoe material preparation method of this luminous EVA sole comprises the steps:

[0065] Step 100, the raw materials are weighed according to the components in Example 2 for use;

[0066] Step 200, putting each raw material in order to carry out the banburying process to obtain the banbury mixture;

[0067] Described banbury...

Embodiment 3

[0082] The invention provides a shoe material with a luminous EVA sole, comprising the following components in parts by weight:

[0083] 70 parts of ethylene-vinyl acetate copolymer resin; 12 parts of ethylene-octene block copolymer; 30 parts of polyolefin elastomer; 10 parts of EPDM rubber; 20 parts of luminous powder; 1 part of bridging agent; 0.2 parts of lubricant -0.5 parts; 5 parts of flow agent; 10 parts of filler; 7 parts of anti-wear agent; 0.5 parts of catalyst; 6 parts of foaming agent.

[0084] The luminous powder includes aluminate luminescent rare earth; the foaming agent is azodicarbonamide ADC foaming agent.

[0085] like figure 1 Shown, the shoe material preparation method of this luminous EVA sole comprises the steps:

[0086] Step 100, the raw materials are weighed according to the components in Example 3 and ready for use;

[0087] Step 200, putting each raw material in order to carry out the banburying process to obtain the banbury mixture;

[0088] De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com