Automatic winding machine

An automatic winding machine and winding technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problem of labor-intensive manual yarn finding, high cost of winding machine use, and a large amount of labor. and other problems, to achieve the effect of efficient and reliable yarn feeding, preventing yarn breakage and eliminating mesh yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

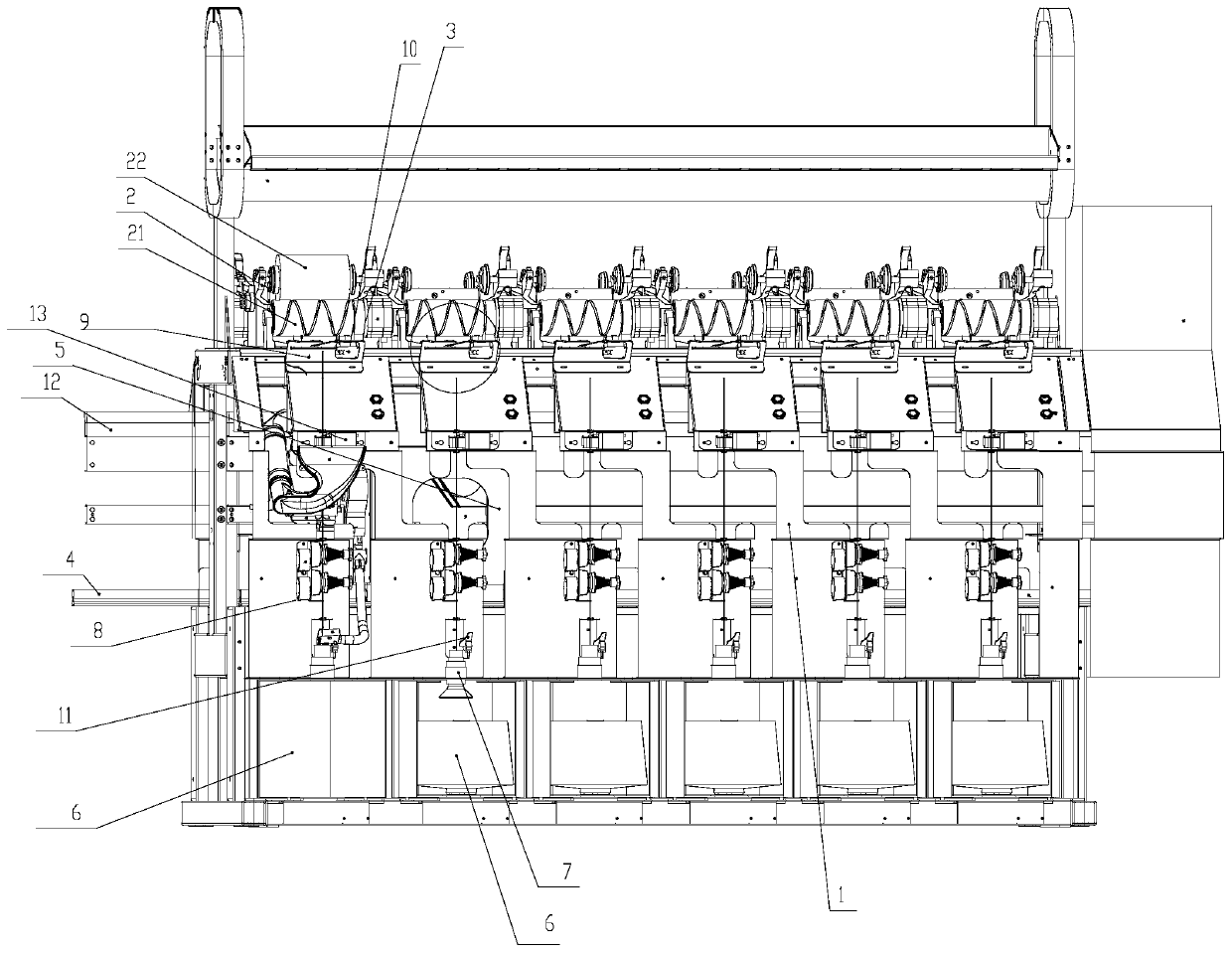

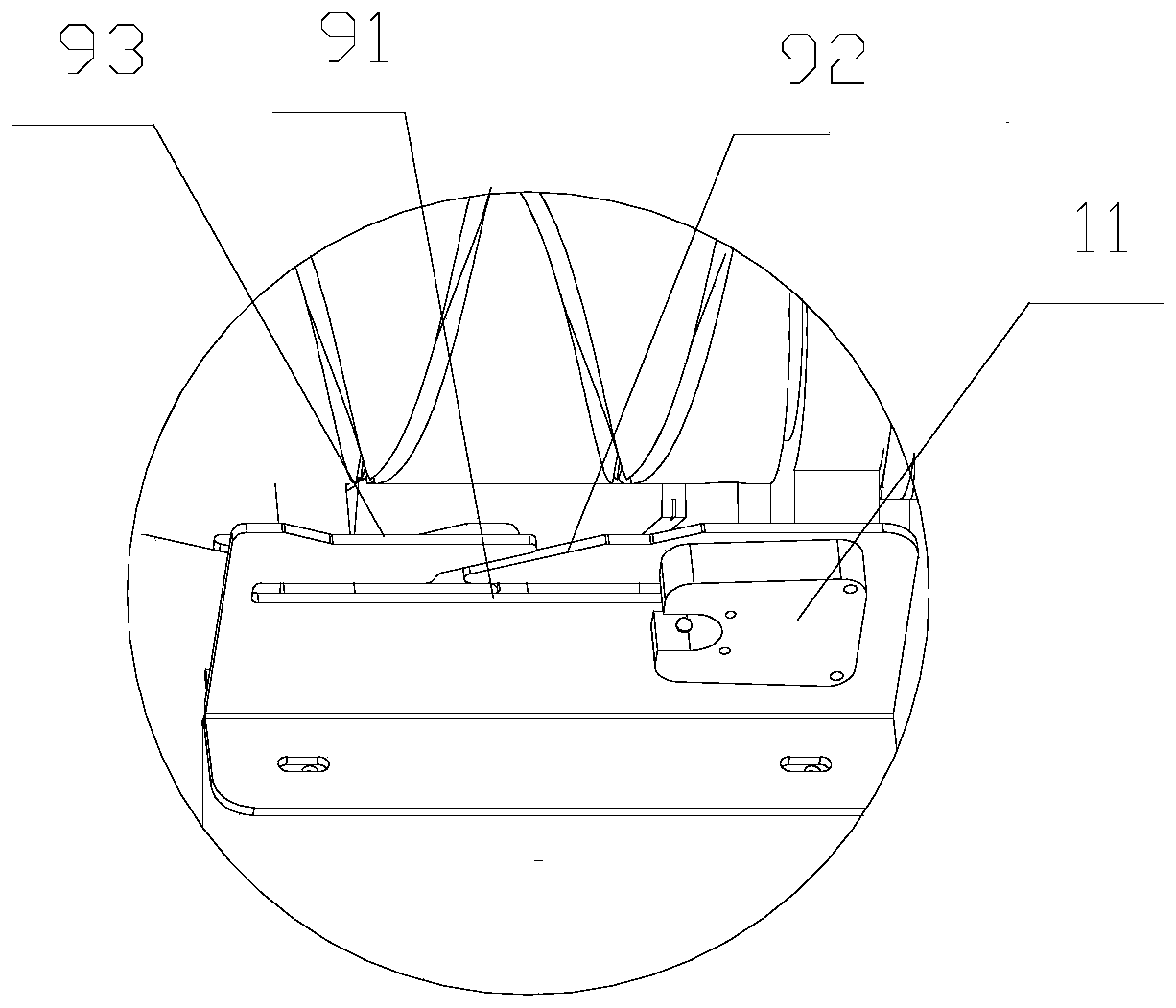

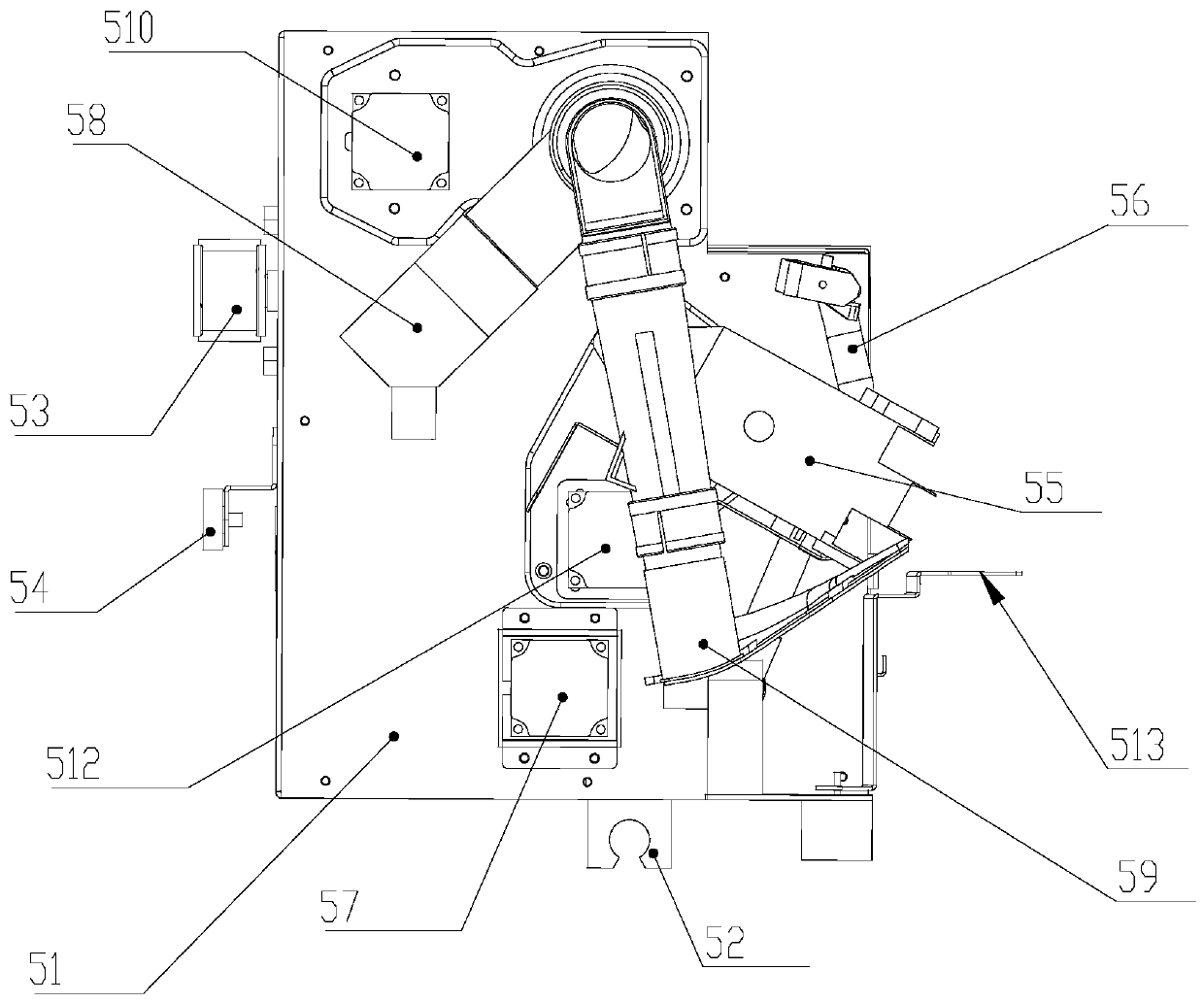

[0026] Such as Figure 1-6 As shown, a kind of automatic winder, comprises frame 1, is provided with several winder assemblies 2 and the winder motor 3 of drive winder assembly 2 on frame 1, on frame 1 below each winder assembly 2 An electronic yarn clearer 13 is provided, and the frame 1 is provided with a horizontal sliding rail 4 below the position of the electronic yarn clearer 13, and a knotting box assembly 5 is provided for sliding on the horizontal sliding rail 4, and a number of corresponding In the yarn supply device 6 of each winding assembly 2, the frame 1 is provided with an air suction device 7 above the yarn supply device 6; 1 is provided with a cradle assembly 32 above the groove drum 31, and a yarn bobbin is detachably provided on the cradle assembly 32; a yarn tension waxing device 8 is provided above the yarn supply device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com