Narrow-space multi-dimensional centering conveying device

A technology for conveying devices and narrow spaces, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve problems such as poor bottom space, difficult maintenance, mechanical wear, etc., achieve compact structure, solve linkage problems, The effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

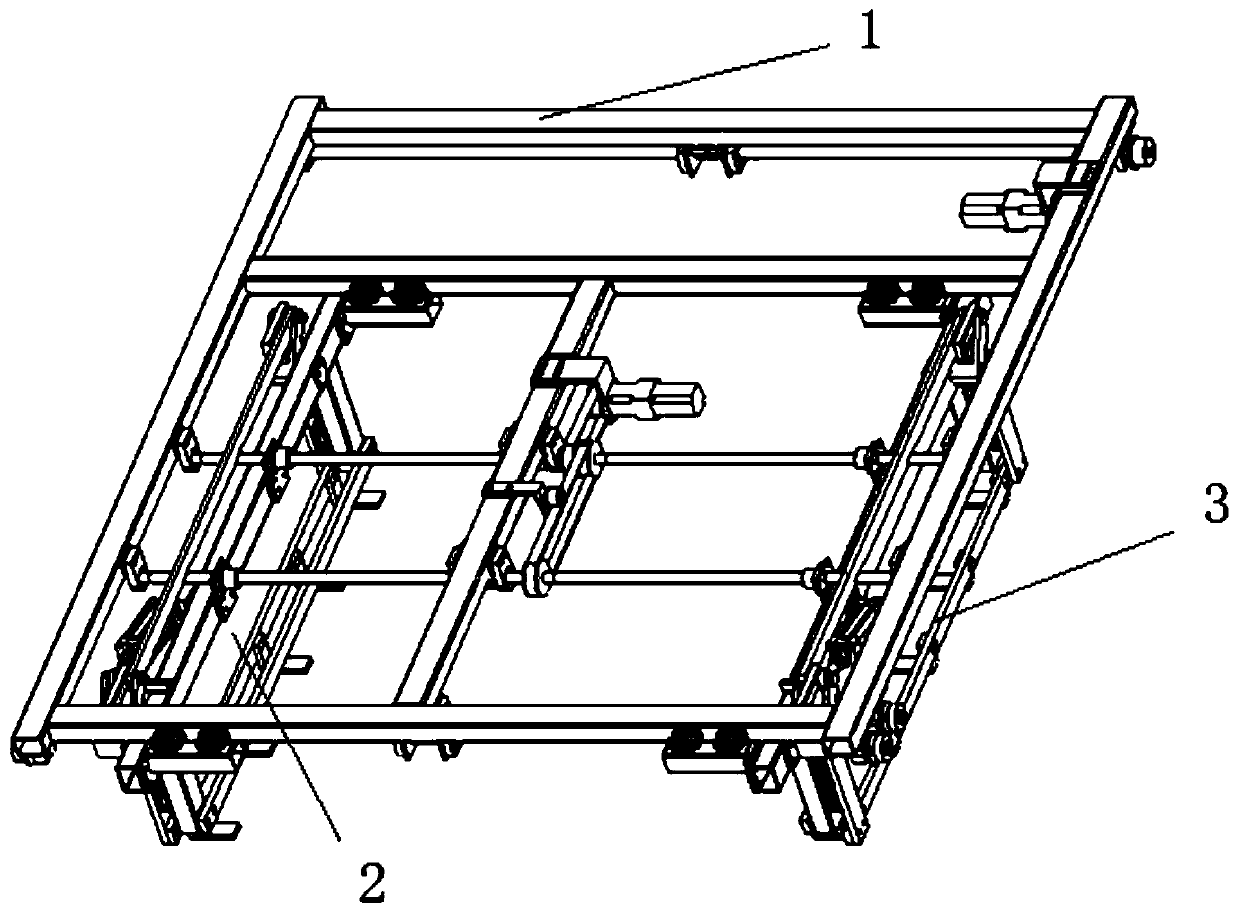

[0041] A narrow-space multi-dimensional centering conveying device, its structure see figure 1 shown, including:

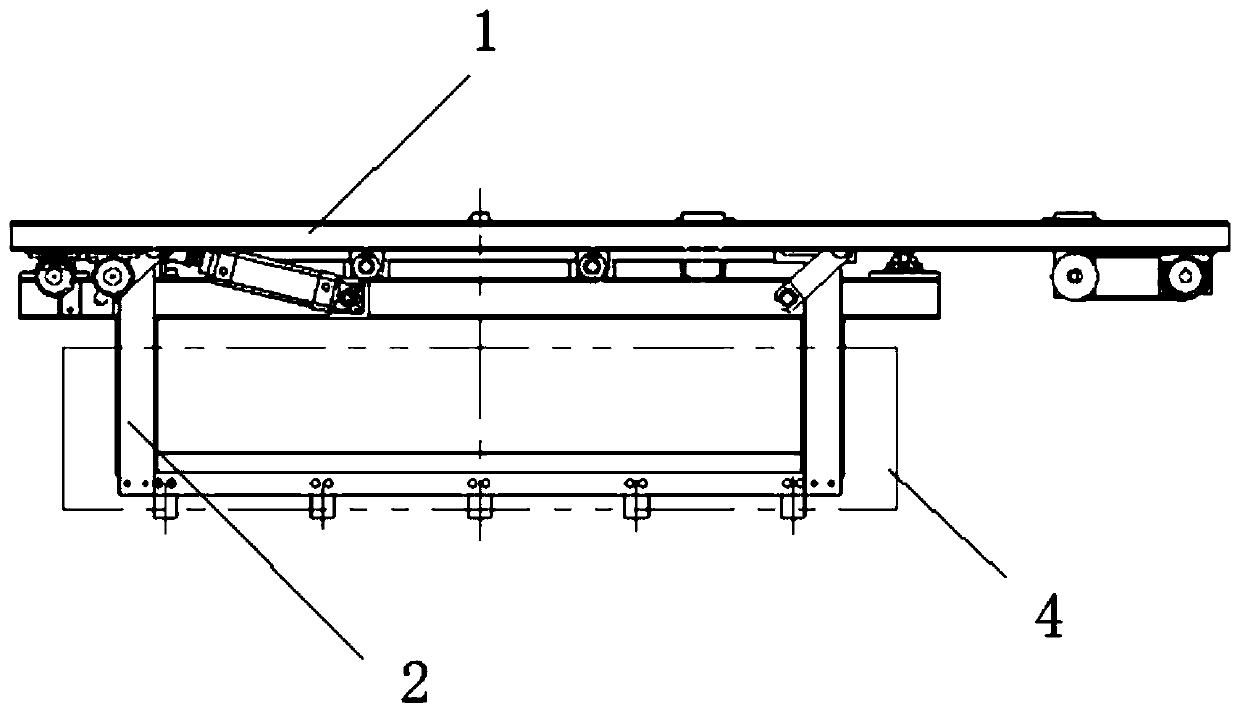

[0042]Walking conveying mechanism 1 arranged on the conveying track: see figure 2 As shown, it includes a main frame 11, a moving wheel assembly mounted on the main frame 11 and matched with the conveying track, and a walking drive assembly that drives the moving wheel assembly to move longitudinally along the conveying track;

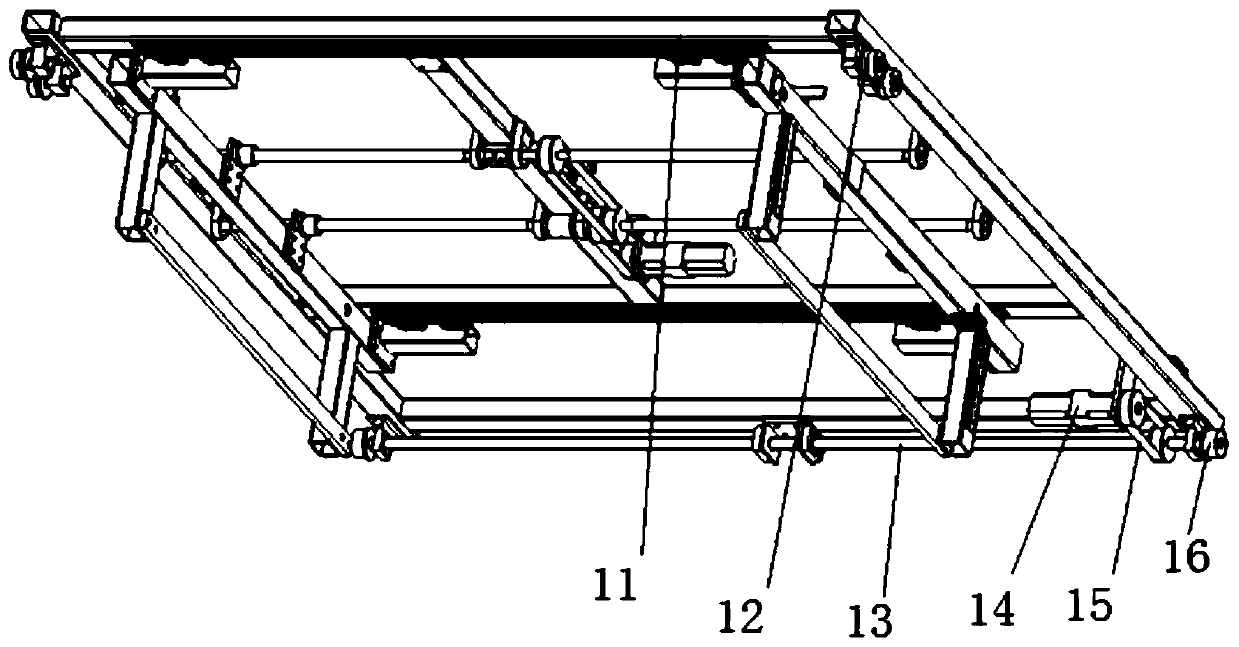

[0043] Centering Clamping Mechanism 2: See image 3 As shown, it includes two parallel clamping beams 22 arranged on the main frame 11 along the lateral movement, and a centering drive assembly that drives the two clamping beams 22 to move laterally on the main frame 11 and relatively close to or reversely away from;

[0044] Synchronous lifting mechanism 3: see Figure 4 As shown, it includes two movable clamping arms 31 respectively fixedly installed on the outside of the clamping beam 22, and two movable clamping arms 31 respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com