Unidirectional planar sounding device and fixing structure for improving tone quality thereof

A sounding device and a fixed structure technology, applied in the direction of the transducer shell/cabinet/bracket, etc., can solve the problems of reduced volume, small radial bearing force, and more noise, so as to improve bonding stability and increase radial The effect of bearing force and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

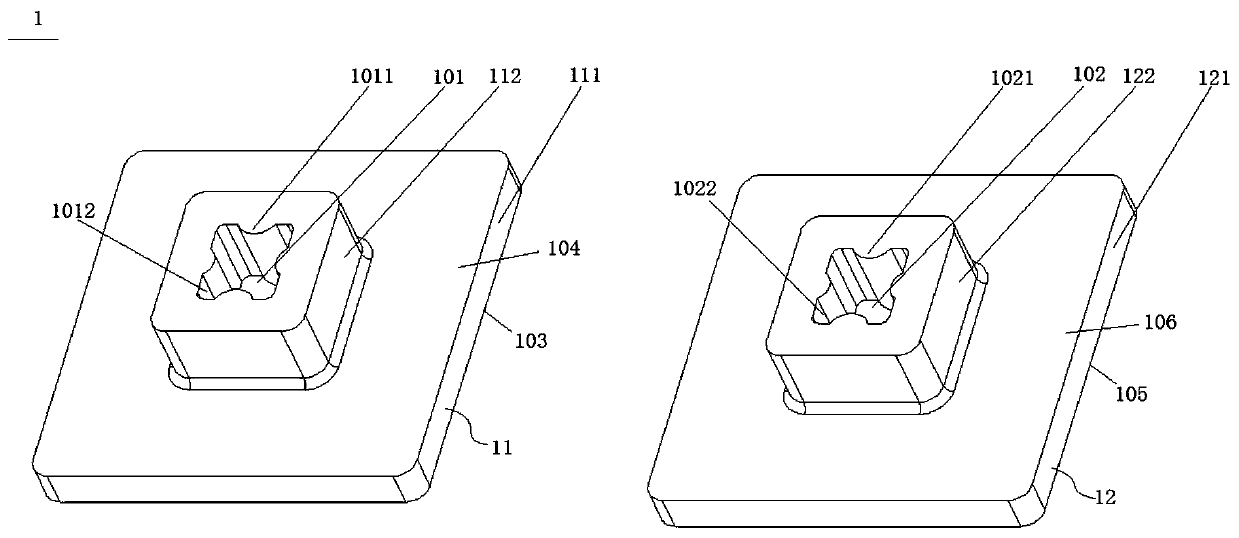

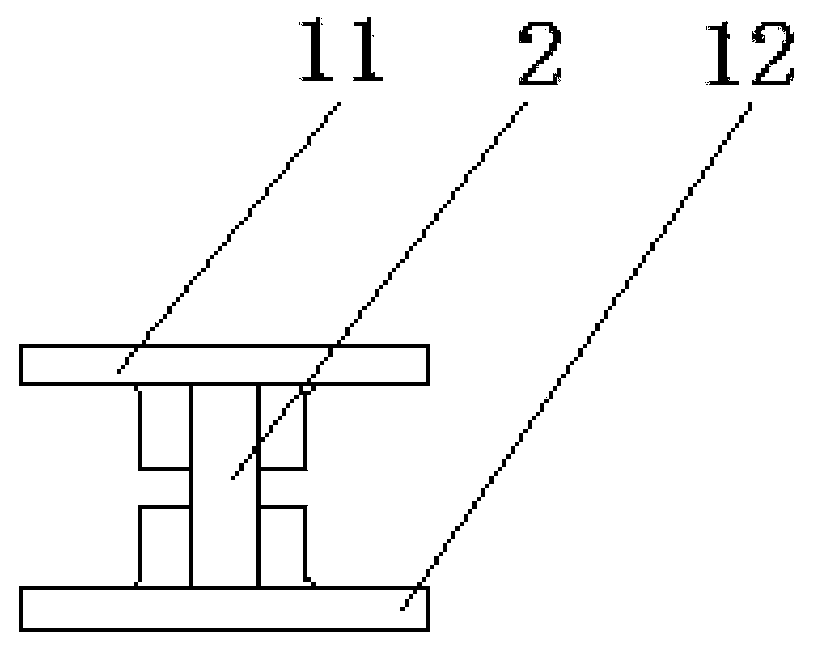

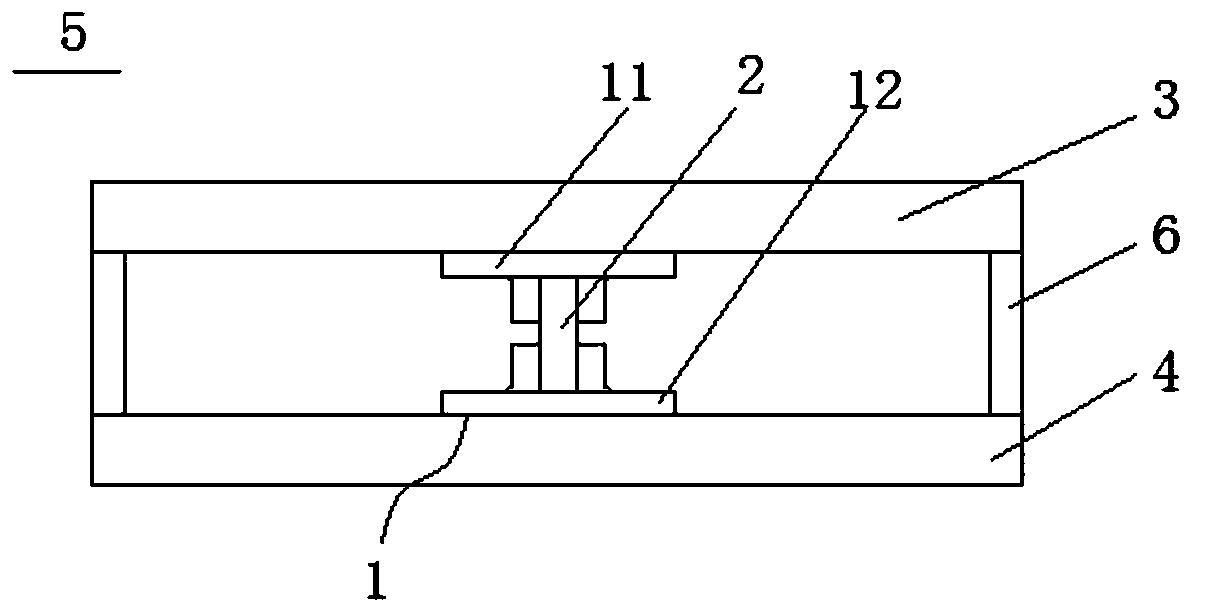

[0047] In an embodiment of the present invention, please refer to figure 1 , which shows a schematic structural view of a fixed structure 1 for improving the sound quality of a unidirectional planar sound emitting device according to an embodiment of the present invention. The fixed structure 1 is used to install and fix the power unit 2 between the vibrating medium 3 and the base 4. The fixed structure 1 includes a first structural member 11 and a second structural member 12, wherein:

[0048]A middle part of one side of the first structural member 11 has a first groove 101 corresponding to one end 201 of the power unit 2 , and the first groove 101 is used for mounting and fixing the one end 201 of the power unit 2 . Please refer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com