Array substrate, display device

A technology for array substrates and display areas, applied in the fields of array substrates and display devices, can solve the problems of high lap resistance between driver chips and binding parts, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

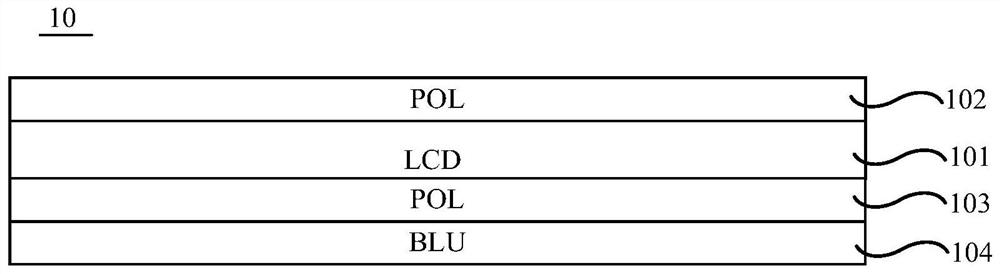

[0143] Since the second insulating layer 24 covers less of the part of the binding part 23 located in the signal transition area C1 , the bonding area of the binding part 23 and the driving circuit is larger, and the bonding resistance is smaller.

[0144] The array substrate 1011 includes at least one signal lead 21 , and the signal lead 21 is disposed on the substrate 20 and at least located in the signal transmission area C2.

[0145] The first insulating layer 22 is disposed on the side away from the signal wire leads away from the substrate 20 ; at least one first via hole 221 is disposed on the first insulating layer 22 .

[0146] At least one binding part 23 is arranged on the side of the first insulating layer 22 away from the substrate 20, and each binding part 23 is electrically connected to a signal line lead through the first via hole 221; Contact area C1.

[0147] The second insulating layer 24 is disposed on the surface of the bonding portion 23 away from the ...

example 2

[0168] Such as Figure 13 As shown, the array substrate 1011 includes at least one signal lead 21, and the signal lead 21 is disposed on the substrate 20 and at least located in the signal transmission area C2.

[0169] The first insulating layer 22 is disposed on the side away from the signal wire leads away from the substrate 20; at least one first via hole 221 is disposed on the first insulating layer 22, and the first via hole 221 is located in the signal transmission area C2.

[0170] At least one binding part 23 is arranged on the side of the first insulating layer 22 away from the substrate 20, and each binding part 23 is electrically connected to a signal line lead through the first via hole 221; the binding part 23 is located at the signal transition area C1 and extends to the signal transmission area C2.

[0171] The second insulating layer 24 is disposed on the surface of the bonding portion 23 away from the substrate 20 , and the second insulating layer 24 covers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com