A dynamic simulation test method for a power system

A dynamic simulation test and power system technology, which is applied in engine testing, machine/structural component testing, instruments, etc., can solve the problem of simulating the total temperature change of the incoming flow for a long time, simulating the total pressure change of the incoming flow for a short time, Problems such as high experimental costs, to achieve the effect of authentic test results, reduced costs, and reduced manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific examples and accompanying drawings.

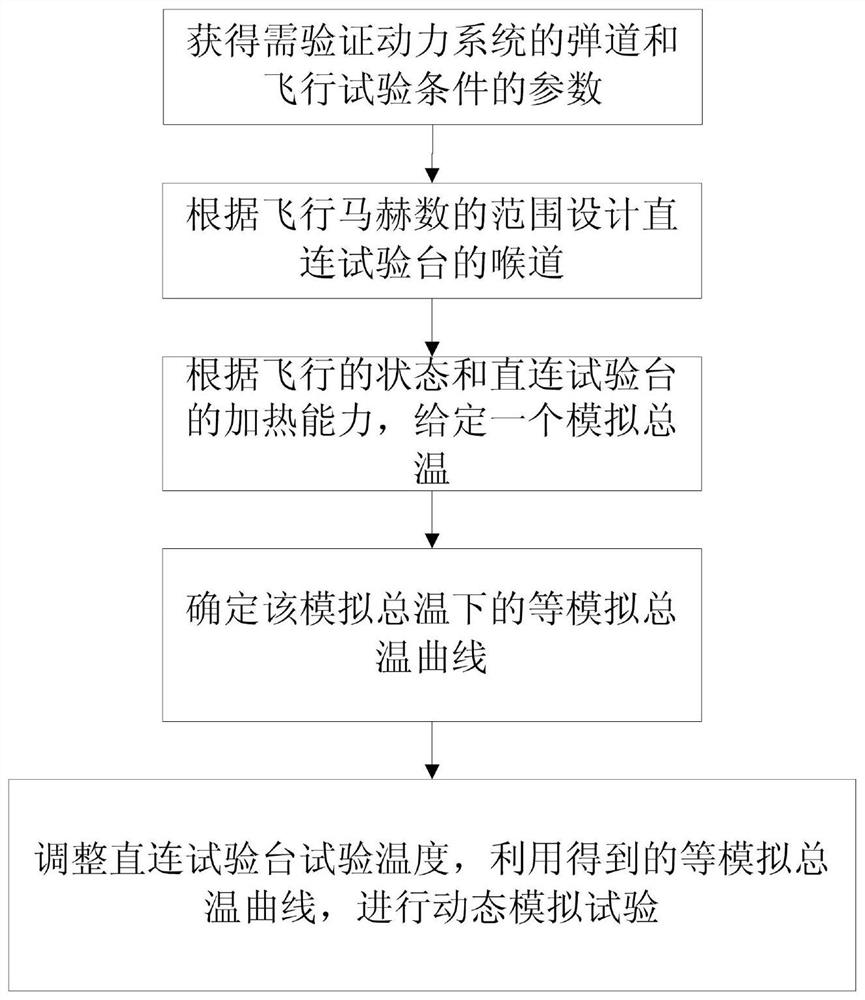

[0031] Such as figure 1 Shown, the technical solution of the present invention: a kind of power system dynamic simulation test method, the steps are as follows,

[0032] Step 1. Obtain the parameters required to verify the ballistic and flight test conditions of the power system, including flight Mach number, flight altitude and ambient static temperature under local flight conditions;

[0033] Among them, the ballistic trajectory needs to be verified. The flight Mach number and flight altitude can be obtained from the trajectory, and the static temperature of the environment under local flight conditions can be measured.

[0034] Step 2. Design the throat directly connected to the test bench according to the range of flight Mach number;

[0035] The throat design steps are:

[0036] S1. Verify the flight Mach number range of the ballistic trajec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com