A method for improving the recovery of natural gas hydrate reservoirs through artificial tight cap rocks

A hydrate and natural gas technology, applied in the fields of fluid production, earthwork drilling, sealing/seal, etc., can solve problems such as restricting the development and utilization of natural gas hydrate reservoirs, affecting the development of natural gas hydrate reservoirs, and limiting the rate of hydrate decomposition. Achieve the effect of simple structure, increase pressure difference and prevent reservoir collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings, but the implementation scope of the present invention is not limited.

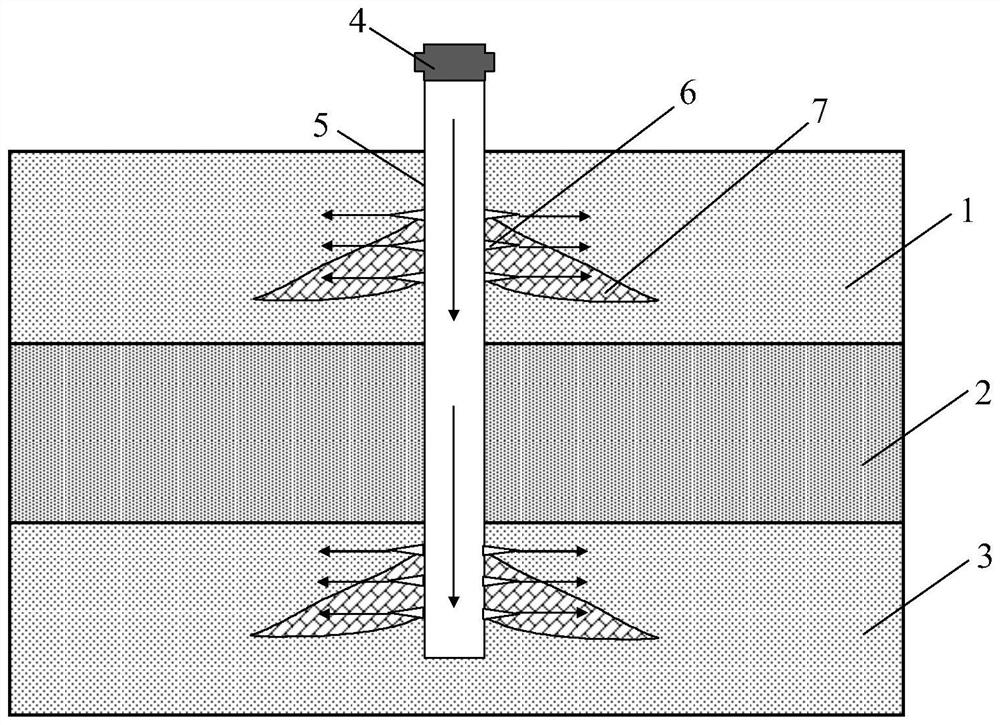

[0028] (1) According to the seismic, well logging and BSR geological data in the study area, the gas hydrate layer 2 with a thickness of 30 m, permeable cap layer 1 and permeable bottom cap layer 3 with a permeability of 20 mD is selected Hydrate reservoirs are mining objects, such as figure 1 shown;

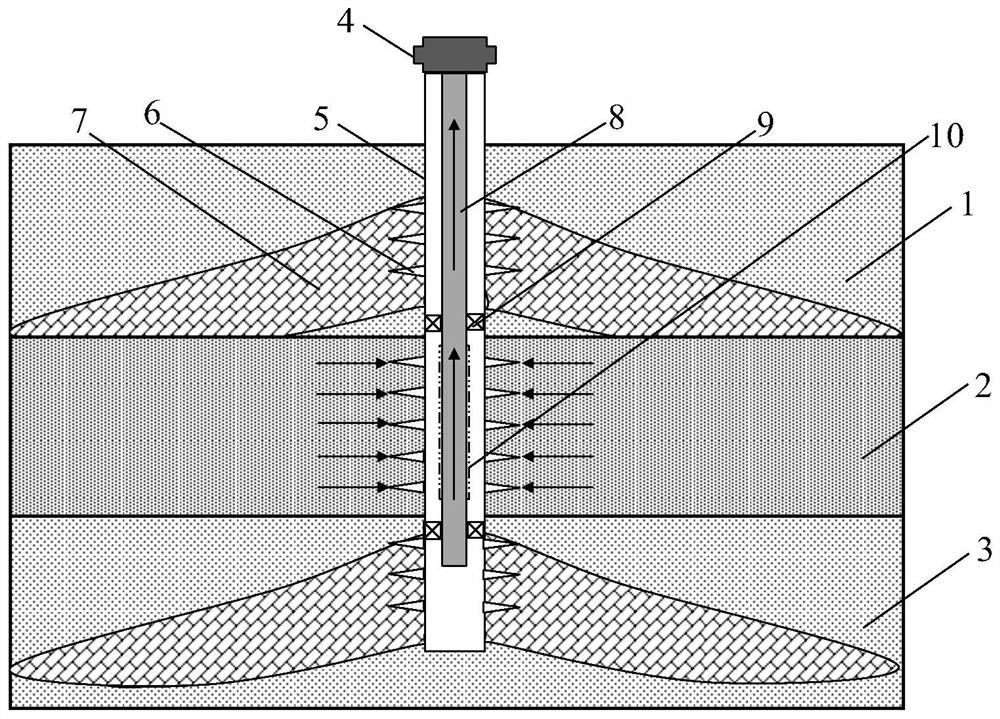

[0029] (2) if figure 1 As shown, a vertical well was drilled in the natural gas hydrate reservoir, and the completion layer was located 25m down from the interface between the hydrate layer 2 and the permeable bottom cap layer 3. The casing 5 in the permeable top cover layer 1 and the permeable bottom cover layer 3 are perforated 6 respectively, and the lowest perforation point in the permeable top cover layer 1 is located at the intersection of the hydrate layer 2 and the permeable top cover layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com