Oil and rust remover for metal surface

A metal surface and rust remover technology, applied in the field of cleaning agents, can solve problems such as corrosion of equipment and the environment, easy formation of acid mist, and increased costs, so as to avoid oxidative corrosion, inhibit the corrosion process, and reduce the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

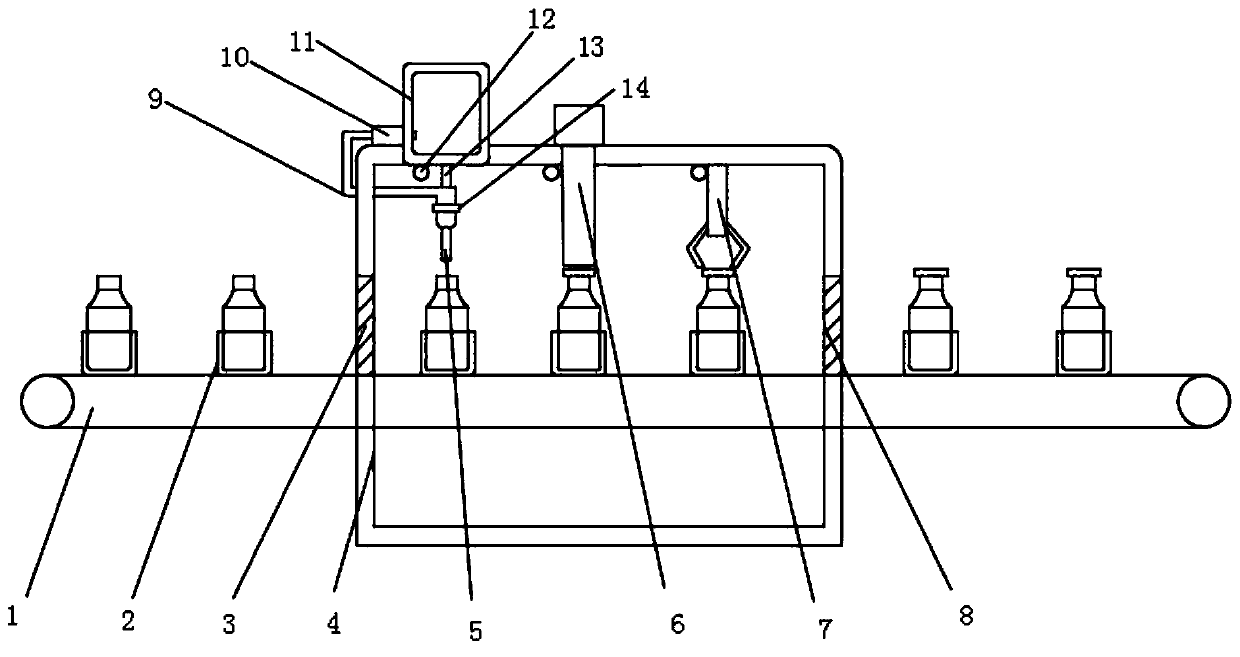

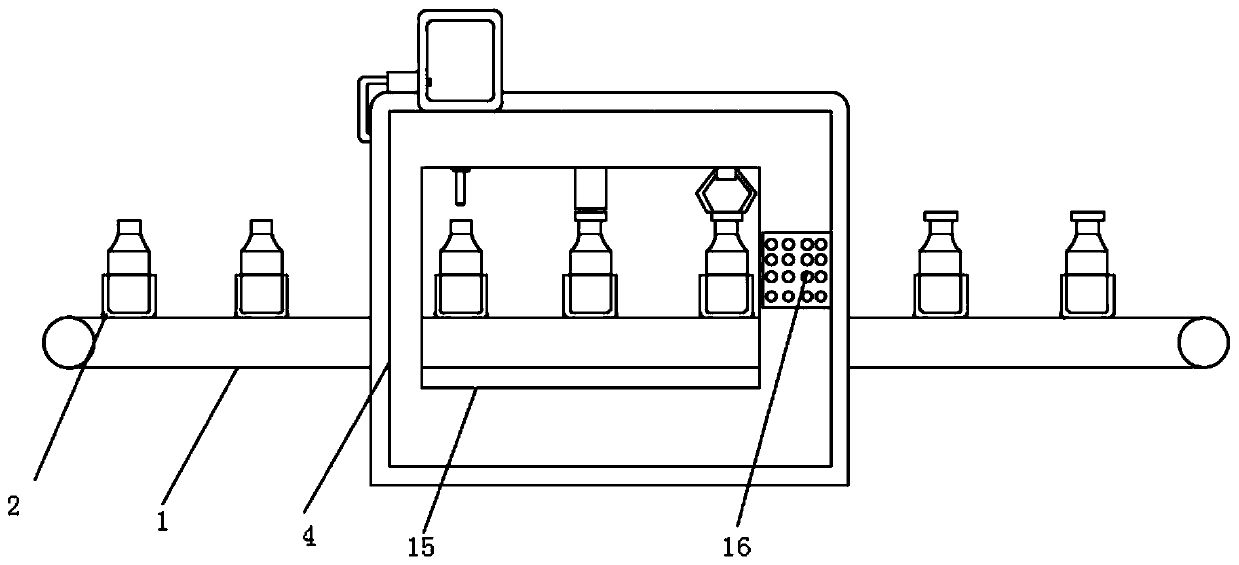

Image

Examples

Embodiment 1

[0037] A metal surface degreasing and rust removing agent, which is prepared from the following raw materials in parts by weight, 2 parts of hydrochloric acid, 3 parts of oxalic acid, 2 parts of citric acid, 3 parts of ascorbic acid, 3 parts of complexing agent, 2 parts of Corrosion inhibitor, 2 parts of penetration enhancer, 2 parts of surfactant, 50 parts of water;

[0038] Wherein, the oil and rust remover is prepared through the following steps:

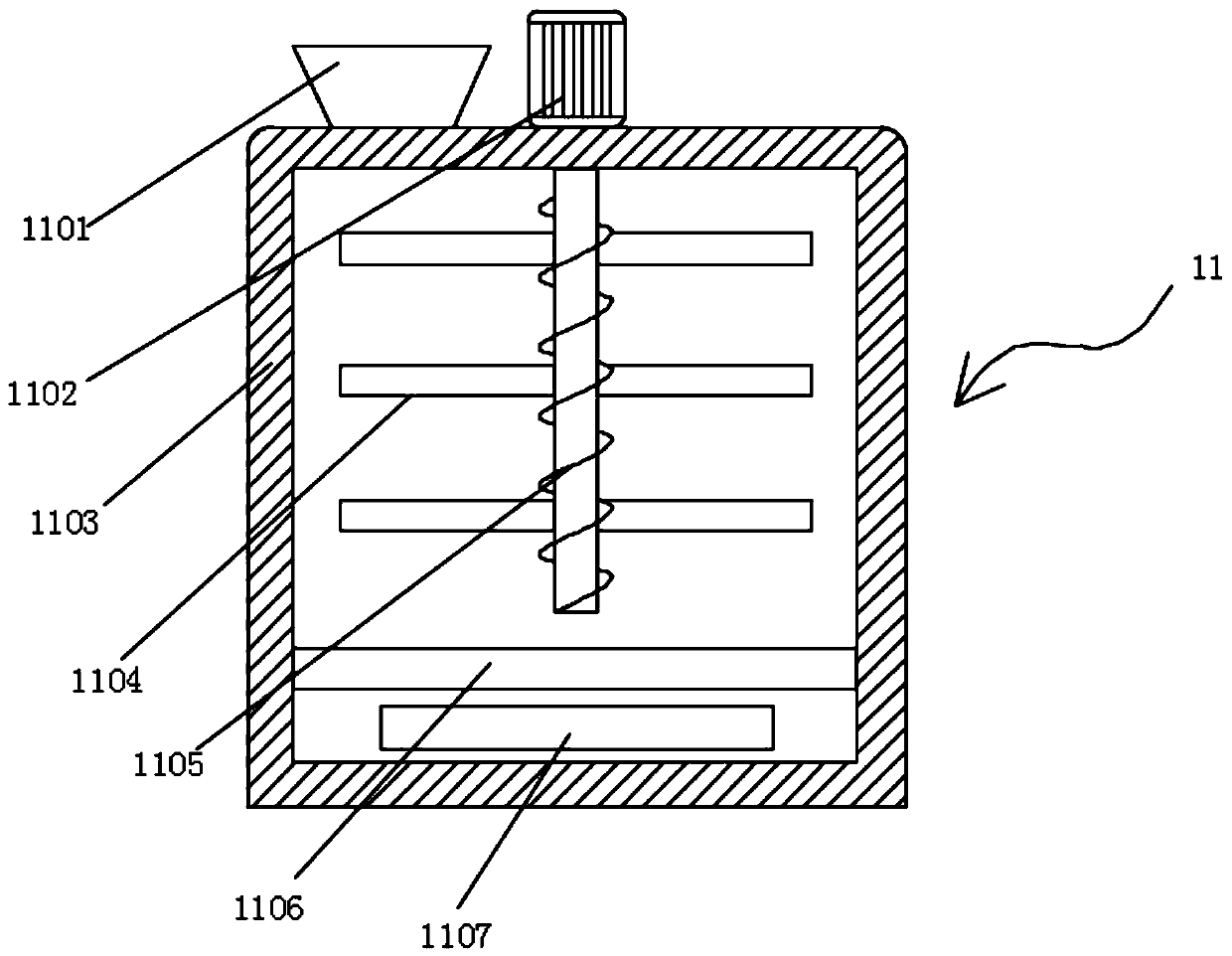

[0039] Step 1. Add 400mL of water to the reaction kettle 11 of the filling equipment, and then slowly heat up the heating element 1107 to 30°C. At this time, drive the rotating motor 1102 to start stirring, and add the corrosion inhibitor while stirring, and stir for 10 Minutes to fully dissolve;

[0040] Step 2, add sodium dodecylsulfonate and sodium dodecylbenzenesulfonate to step 1, stir and mix for 5 minutes to make it all dissolve, then slowly add dissolved hydrochloric acid, oxalic acid, citric acid and ascorbic acid, Mak...

Embodiment 2

[0047] A metal surface degreasing and rust removing agent, which is prepared from the following raw materials in parts by weight, 4 parts of hydrochloric acid, 6 parts of oxalic acid, 4 parts of citric acid, 5 parts of ascorbic acid, 6 parts of complexing agent, 5 parts of Corrosion inhibitor, 4 parts of penetration enhancer, 6 parts of surfactant, 90 parts of water;

[0048] Wherein, the oil and rust remover is prepared through the following steps:

[0049] Step 1. Add 400mL of water to the reaction kettle 11 of the filling equipment, and then slowly heat up the heating element 1107 to 50°C. At this time, drive the rotating motor 1102 to start stirring, and add the corrosion inhibitor while stirring, and stir for 15 Minutes to fully dissolve;

[0050] Step 2, add sodium dodecylsulfonate and sodium dodecylbenzenesulfonate to step 1, stir and mix for 10 minutes, make it completely dissolved, then slowly add dissolved hydrochloric acid, oxalic acid, citric acid and ascorbic aci...

Embodiment 3

[0057] A metal surface degreasing and rust removing agent, which is prepared from the following raw materials in parts by weight, 2 parts of hydrochloric acid, 6 parts of oxalic acid, 2 parts of citric acid, 5 parts of ascorbic acid, 3 parts of complexing agent, 5 parts of Corrosion inhibitor, 2 parts of penetration enhancer, 6 parts of surfactant, 50 parts of water;

[0058] Wherein, the oil and rust remover is prepared through the following steps:

[0059] Step 1. Add 400mL of water to the reaction kettle 11 of the filling equipment, and then slowly heat up the heating element 1107 to 30°C. At this time, drive the rotating motor 1102 to start stirring, and add the corrosion inhibitor while stirring, and stir for 15 Minutes to fully dissolve;

[0060] Step 2, add sodium dodecylsulfonate and sodium dodecylbenzenesulfonate to step 1, stir and mix for 10 minutes, make it completely dissolved, then slowly add dissolved hydrochloric acid, oxalic acid, citric acid and ascorbic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com