Double-drive hole wall machining system and method

A processing system and hole wall technology, which is applied in the field of hole wall processing, can solve problems such as strengthening the inner surface of difficult workpieces, and achieve the effect of good surface quality and good cavitation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

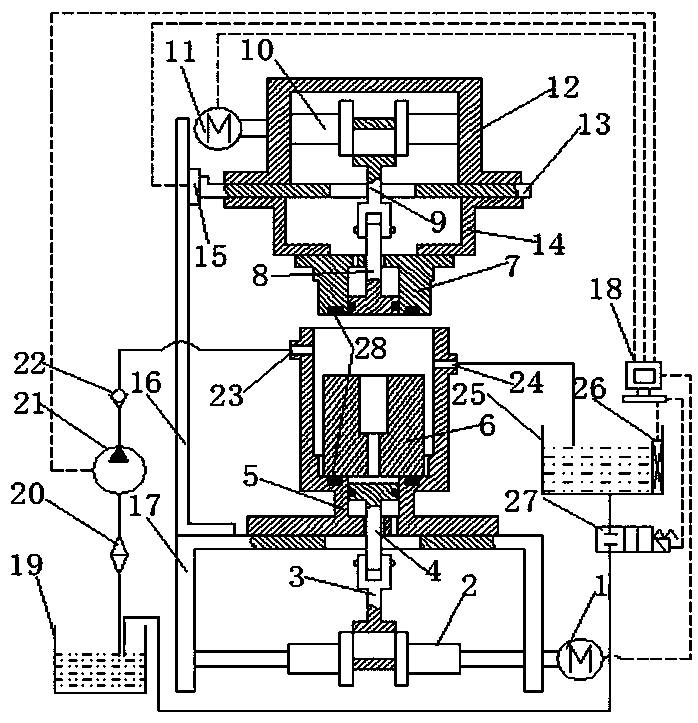

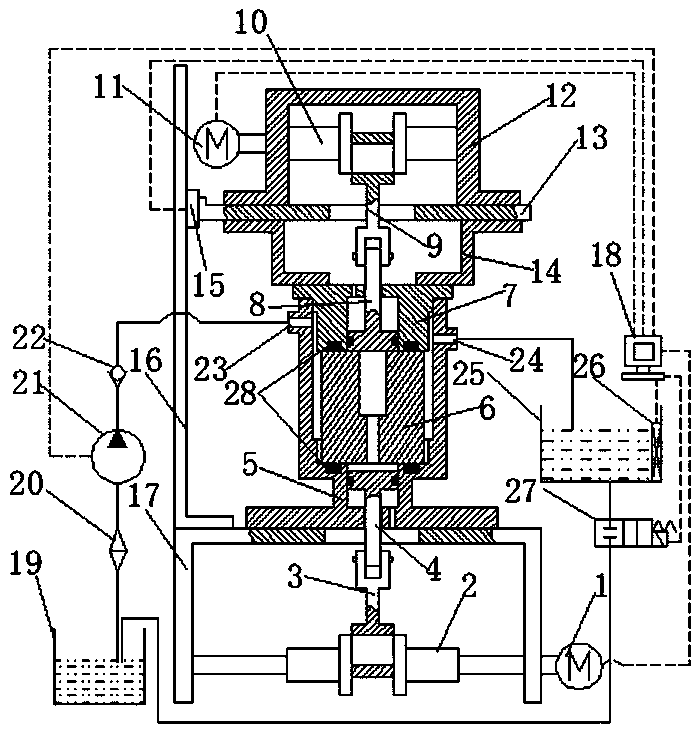

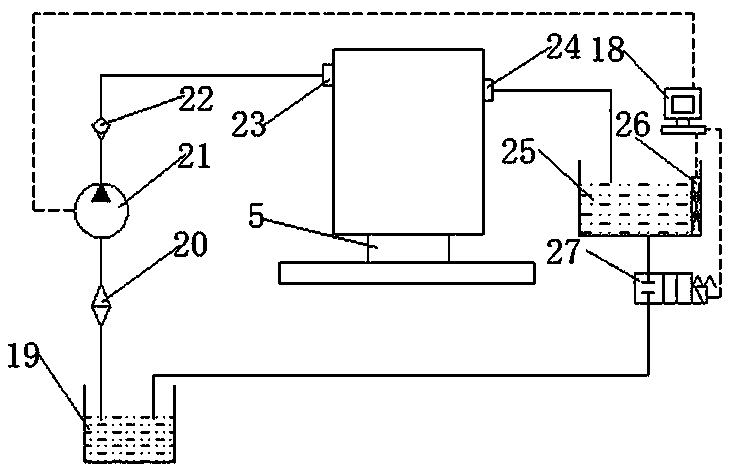

[0021] see Figure 1 to Figure 3 The present invention provides a dual-drive hole wall processing system including a liquid supply system, a cavitation generation system, a horizontal workbench base 17, a vertical workbench base 16, a vertically movable workbench 15, a bracket 13, and a Z-shaped pressing plate 14 and controller 18.

[0022] The cavitation generation system includes a drive motor one 1, a crankshaft one 2, a connecting rod one 3, a piston one 4, a piston cylinder 5, a workpiece 6, a sealing cover 7, a piston two 8, a connecting rod two 9, a crankshaft two 10, a drive Motor two 11, crankcase 12 and sealing ring 28. Described crankshaft-2 is arranged horizontally, and the bearing is connected below the horizontal table base 17, and one end of crankshaft-2 is fixedly connected to the output shaft of drive motor-1 coaxially, and is driven to rotate by drive motor-1. The lower end of the connecting rod 1 is connected to the middle part of the crankshaft 2 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com