Preparation method and application of plastic with surface being grafted with graphene and anthraquinone compound

A technology of surface grafting and graphene, applied in chemical instruments and methods, water pollutants, biological water/sewage treatment, etc., can solve problems such as weak binding force, achieve low cost, increase biodegradation rate, source wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

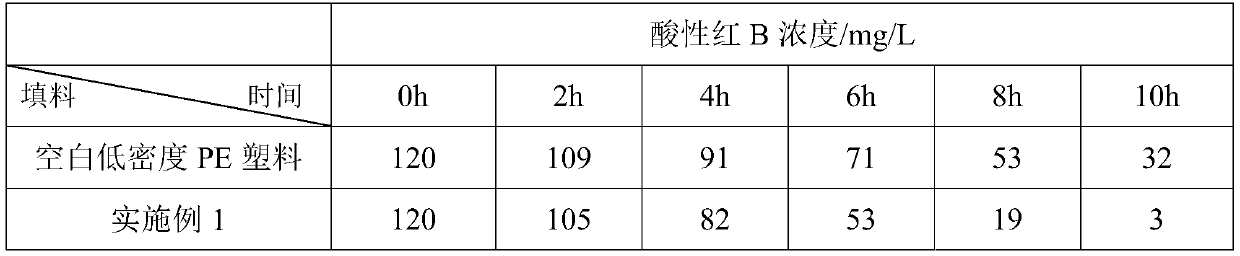

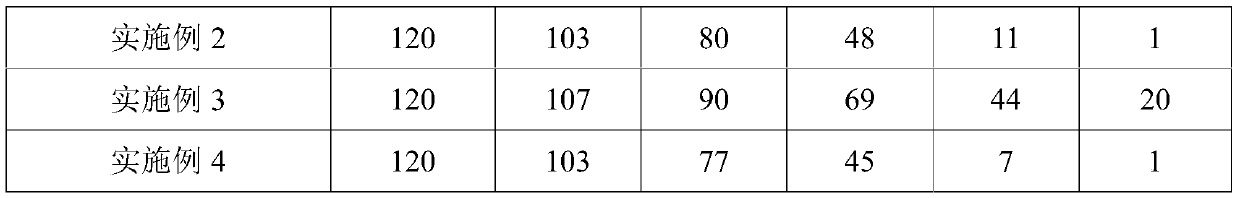

Examples

Embodiment 1

[0039] Preparation of PE plastic with hydrophilic surface: use ozone to modify the surface of low-density PE plastic with an average particle size of 0.2mm;

[0040] Preparation of amino-modified low-density PE plastics: add 6 parts of 3-aminopropyltrimethoxysilane to 100 parts of alcohol aqueous solution with a volume ratio of 95:5, stir for half an hour, and add 30 parts of the above-mentioned low-density PE with hydrophilic surface For plastic, heat up to 55°C, react for 3 hours, filter, filter out the solid, wash it three times with absolute ethanol, and dry;

[0041] Preparation of low-density PE plastic with graphene oxide grafted on the surface: add 1 part of modified Hummers method graphene oxide to 700 parts of tetrahydrofuran, ultrasonically disperse, add 8 parts of the above-mentioned amino-modified low-density PE plastic, and stir for 1 hour , filtered, the filtered solid was washed three times with absolute ethanol, and dried;

[0042] Preparation of low-density ...

Embodiment 2

[0046] Preparation of PP plastic with hydrophilic surface: use plasma to modify the surface of PP plastic with an average particle size of 0.05mm;

[0047] Preparation of amino-modified PP plastic: Add 8 parts of 3-aminopropyltriethoxysilane to 100 parts of alcohol aqueous solution with a volume ratio of 95:5, stir for half an hour, add 40 parts of the above-mentioned PP plastic with a hydrophilic surface, and heat up to 70°C, reacted for 1.5 hours, filtered, and the filtered solid was washed three times with absolute ethanol, and dried;

[0048] Preparation of PP plastic with graphene oxide grafted on the surface: add 1 part of modified Hummers method graphene oxide to 500 parts of tetrahydrofuran, ultrasonically disperse, add 40 parts of the above-mentioned amino-modified PP plastic, stir for 1 hour, filter, and filter out The solid was washed three times with absolute ethanol and dried;

[0049] Preparation of PP plastic surface-grafted graphene and anthraquinone compound:...

Embodiment 3

[0052] Preparation of semi-soft filler with hydrophilic surface: use ion beam to modify the surface of semi-soft filler to hydrophilicity;

[0053] Preparation of amino-modified semi-soft filler: Add 5 parts of 3-aminopropylmethyldiethoxysilane to 100 parts of alcohol aqueous solution with a volume ratio of 95:5, stir for half an hour, add 40 parts of the above-mentioned surface affinity Water semi-soft filler, heated to 70°C, reacted for 2 hours, filtered, the filtered solid was washed three times with absolute ethanol, and dried;

[0054] Preparation of semi-soft fillers with surface-grafted graphene oxide: add 1 part of modified Hummers method graphene oxide to 8000 parts of tetrahydrofuran, ultrasonically disperse, add 25 parts of the above-mentioned amino-modified semi-soft fillers, and stir for 2 hours. Filter, filter out the solid, wash three times with absolute ethanol, and dry;

[0055] Preparation of plastics with surface grafted graphene and anthraquinone compounds...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com