Preparation method of epoxy resin curing agent

A technology for epoxy resin curing and epoxy compounds, which is applied in the field of preparation of epoxy resin curing agents, can solve the problems of low thermal conductivity, etc., and achieve the effect of simple preparation method, wide range of raw materials, and easy popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The application provides a kind of preparation method of epoxy resin curing agent, and its preparation step comprises:

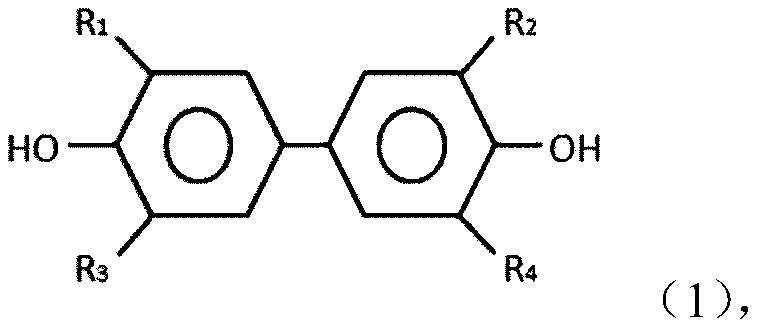

[0022] In step S10, 2 mol of compound A is dissolved in a solvent, wherein compound A is a compound represented by the following general formula (1),

[0023]

[0024] R in general formula (1) 1 , R 2 , R 3 and R 4 independently of each other -H or -CH 3 .

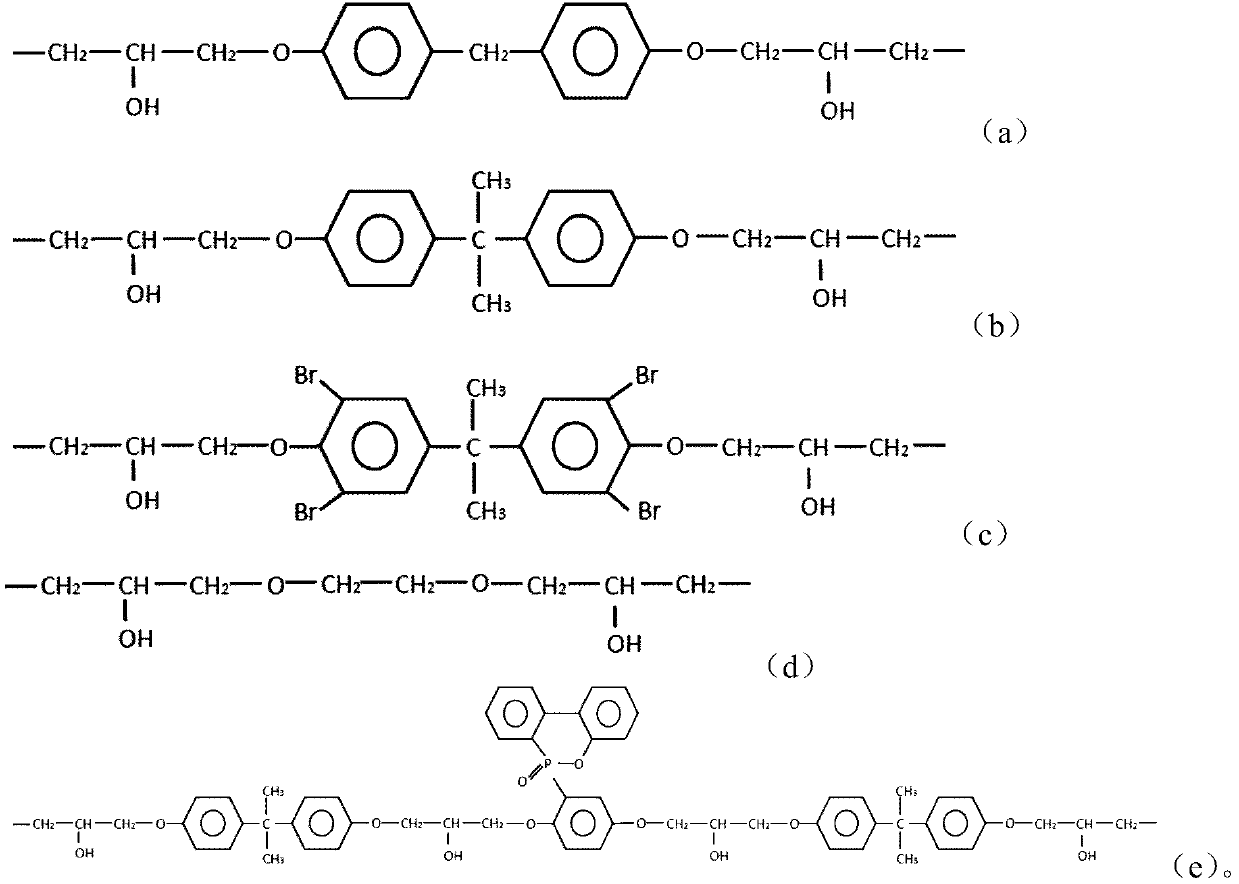

[0025] Step S20, adding 1-1.6 mol of bifunctional epoxy compound into the solvent in which compound A is dissolved.

[0026] In the present application, the difunctional epoxy compound includes one or more of the following five epoxy compounds of I-V,

[0027]

[0028]

[0029] Step S30, uniformly mix the dissolved compound A and the difunctional epoxy compound, raise the temperature to 70-160°C, and react for 1-6h to prepare an epoxy resin curing agent, which includes the following general formula Compounds represented by (2):

[0030]

[0031] In general formula (2), n repres...

Embodiment 1

[0036] The preparation process of epoxy resin curing agent comprises:

[0037] Take 90g of bisphenol A type epoxy with an epoxy equivalent of 175-185g / eq and 93g of 4,4-biphenyldiol and dissolve them in DMF, and react at 120-125°C for 2 hours to obtain it. The actual phenolic hydroxyl equivalent is 388g / eq mol.

[0038] In the present embodiment, the structural formula of bisphenol A type epoxy is:

[0039]

[0040] In the present embodiment, the epoxy resin curing agent that makes comprises following compound:

[0041] Among them, R is

[0042]

Embodiment 2

[0044] The preparation process of epoxy resin curing agent comprises:

[0045] Take 85g of bisphenol F-type epoxy with an epoxy equivalent of 160-180g / eq and 93g of 4,4-biphenyldiol and dissolve them in ethylene glycol methyl ether, then add 0.05g of 2-methylimidazole, 120- It can be obtained by reacting at 125°C for 2 hours, and its phenolic hydroxyl equivalent is measured to be 376g / mol.

[0046] In the present embodiment, the structural formula of bisphenol F type epoxy is:

[0047]

[0048] In the present embodiment, the epoxy resin curing agent that makes comprises following compound:

[0049] Among them, R is

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com