A recovery method of petrochemical output gas

A petrochemical and recovery method technology, applied in the petroleum industry, chemical instruments and methods, carbon monoxide, etc., can solve the problems of low output purity, insufficient separation, high energy consumption, etc., to achieve improved purity, simple operation, and energy consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

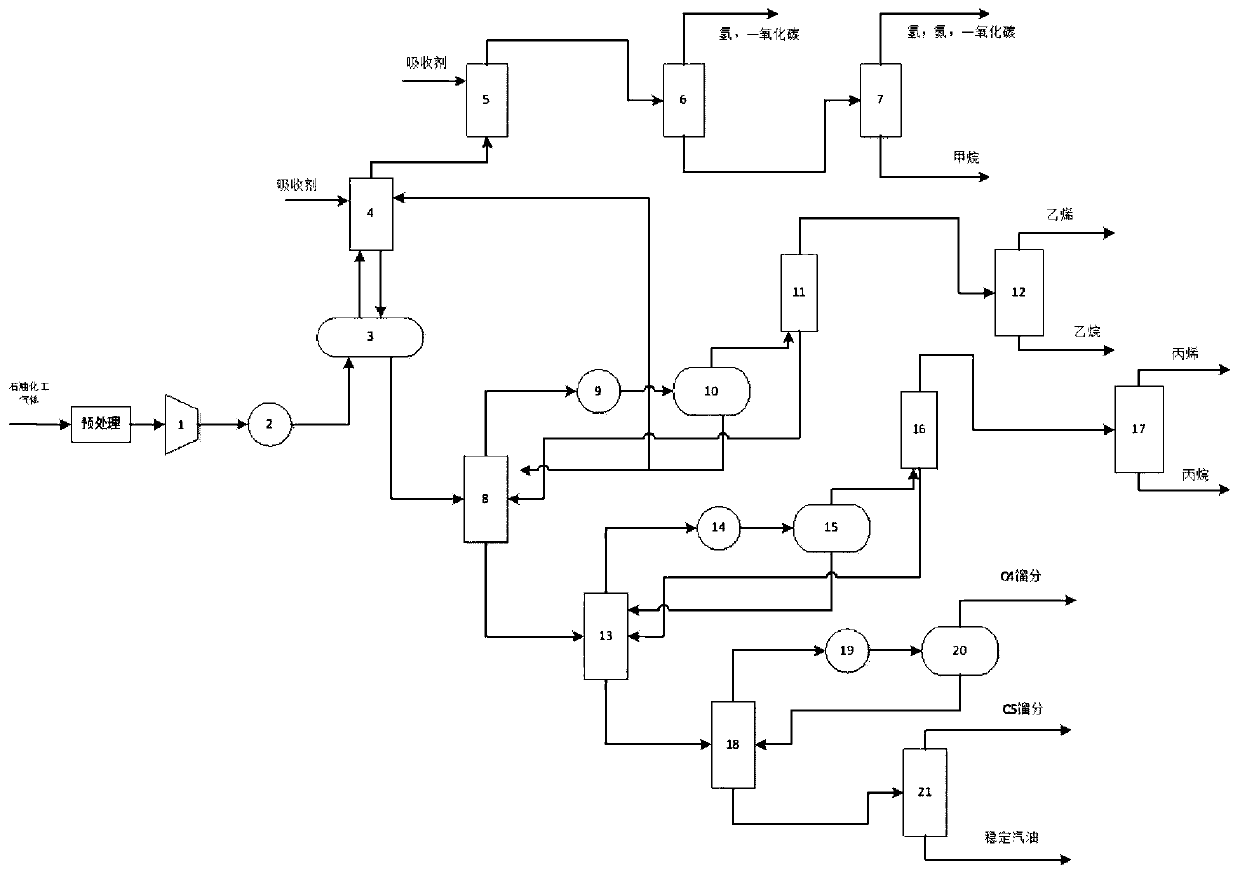

[0022] see figure 1 , the present invention is a kind of petrochemical output gas recovery method, concrete operation steps are as follows:

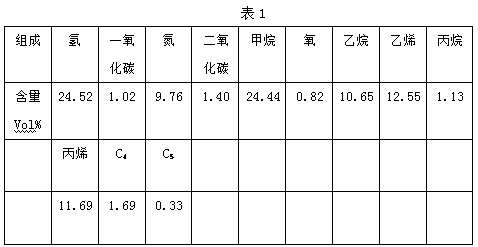

[0023] The gas produced by the petrochemical process is first pretreated to remove free water and impurities, and then the pressure is increased by the compressor 1, and then enters the cooler 2 to cool and dry, and then passes through the balance tank 3 and then flows from the bottom of the first absorption tower 4 Into the tower, the C in the gas is absorbed by the first absorbent in the first absorption tower 4 2 and heavier components to obtain a rich absorption liquid, which is discharged from the bottom of the first absorption tower 4 and enters the balance tank 3 to contact the raw gas, and the gas discharged from the top of the first absorption tower 4 enters the bottom of the second absorption tower 5 , a small amount of C in the gas is further absorbed by the second absorbent in the tower 2 , the gas discharged from the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com