Microsphere probe preparation method based on micro-cantilever transfer

A micro-cantilever and probe technology, which is applied in the photoengraving process, manufacturing tools, welding equipment and other directions of the pattern surface, can solve the problems of high price, easy fork of the needle tip, single probe material, etc., and reduce the loading error. , the effect of increasing the loading range and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

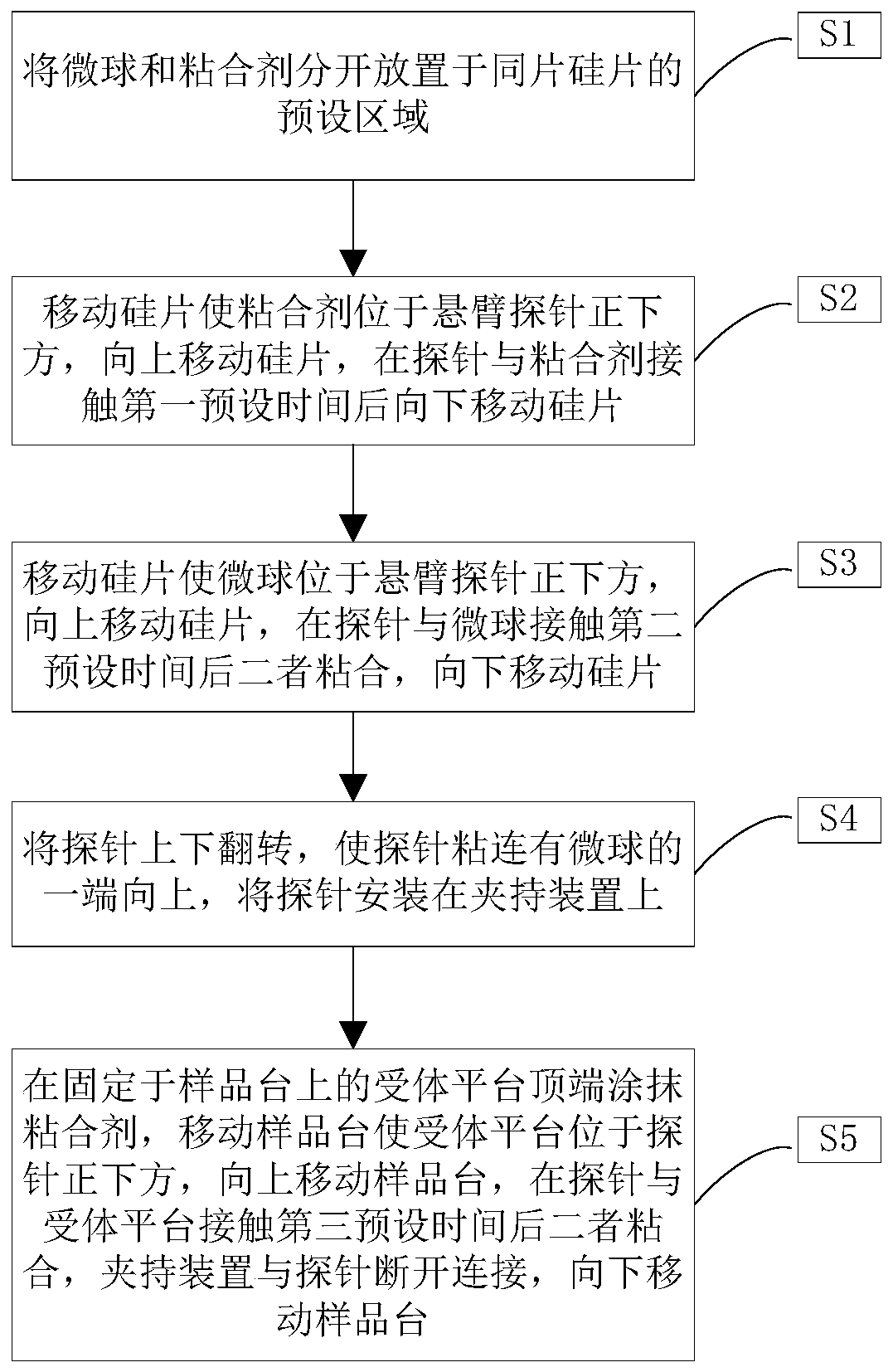

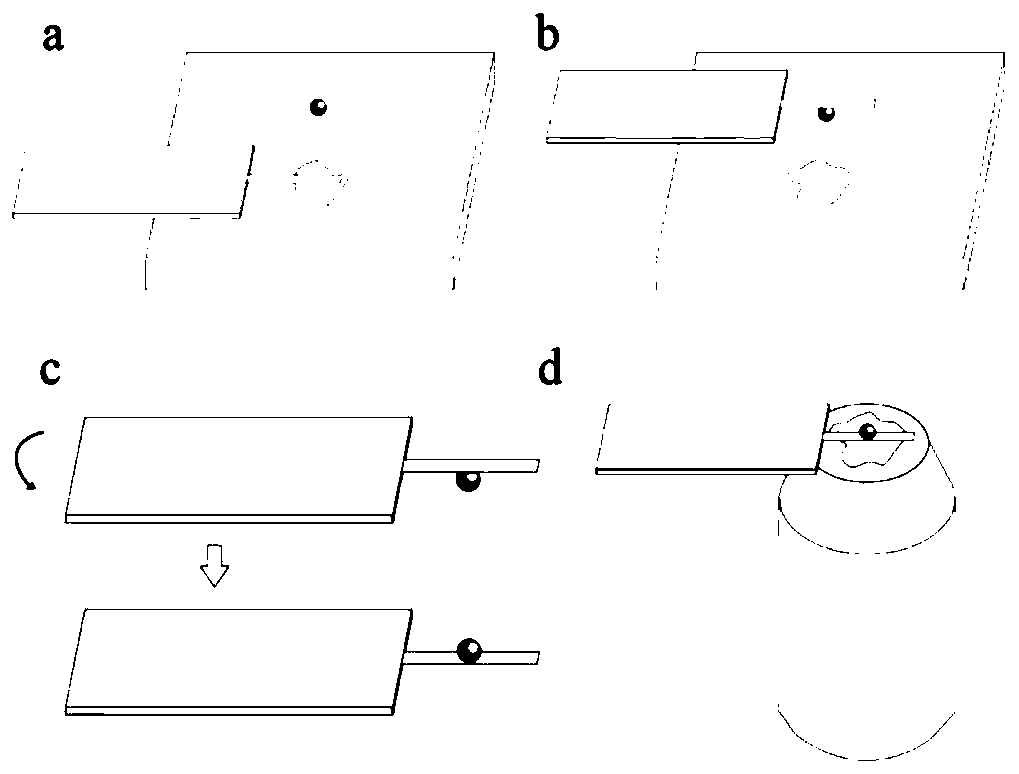

[0026] see figure 1 , a method for preparing microsphere probes based on microcantilever transfer, realized by the following steps:

[0027] S1. Place the microspheres and the adhesive on the first preset area and the second preset area of the silicon wafer respectively, and place the silicon wafer on the sample stage.

[0028] In this embodiment, microspheres of appropriate material and size are selected according to requirements, placed on a predetermined microsphere placement area on the silicon wafer, and the adhesive is placed on another predetermined area on the silicon wafer.

[0029] In this embodiment, the material of the microspheres is not particularly limited, and the size can be changed in a large gradient range from nanometers to millimeters, and the best effect is especially when the radius of curvature is in the range of 50-500 μm. Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com