Chip writing mechanism for chip personalized data writing machine

A technology of data writing and writing mechanism, which is applied in the direction of manipulators, conveyor objects, program-controlled manipulators, etc., can solve the problems of high manufacturing and processing costs and complex structures, and achieve simple and reliable structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

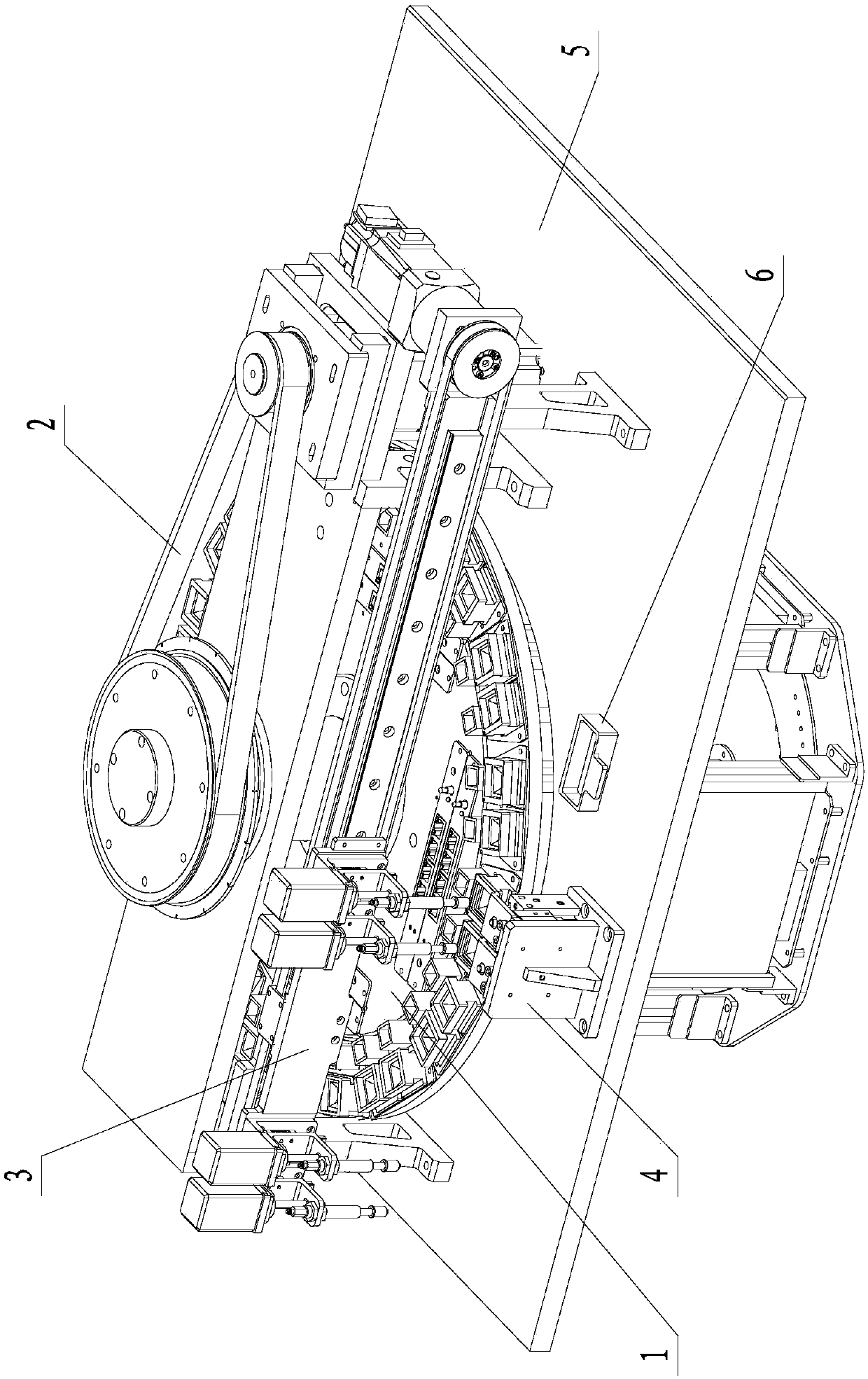

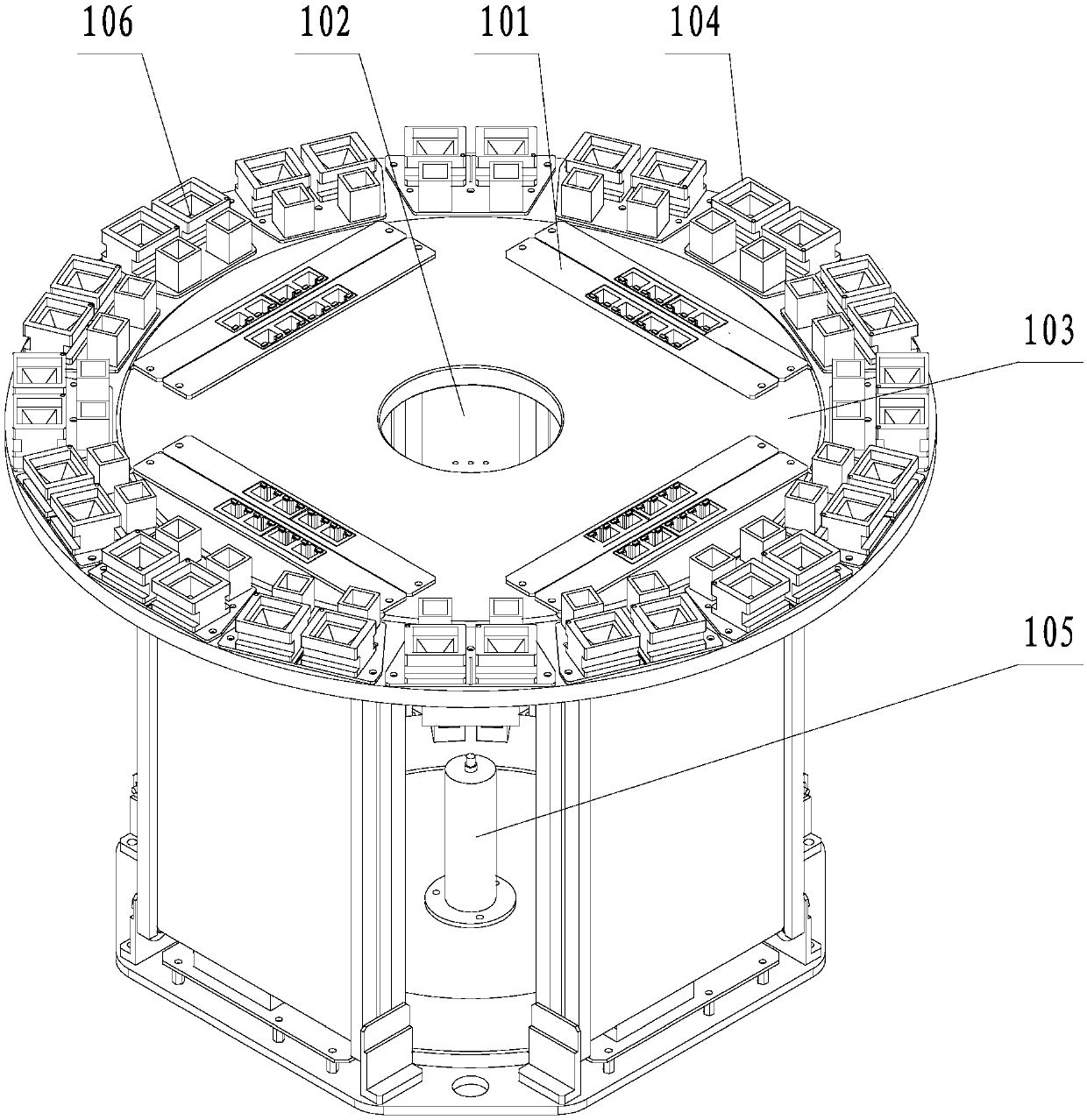

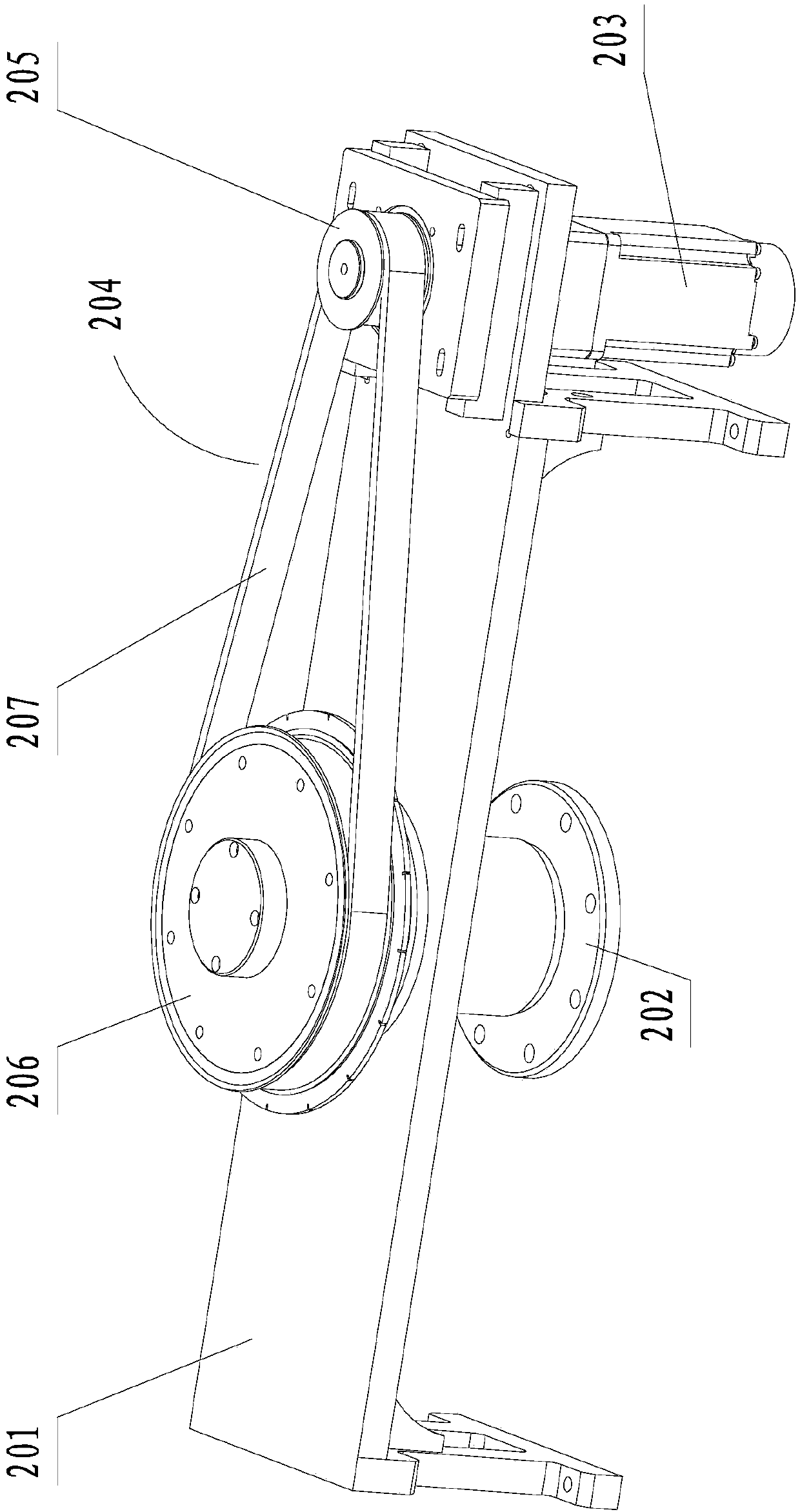

[0027] Such as figure 1 As shown, the present invention includes a writing drum 1, a worktable 5 and a rotating drum power mechanism 2, a mechanical gripper 3, an opening mechanism 4 and a waste chip box 6 respectively installed on the working table 5, wherein writing The input drum 1 passes through the worktable 5 and rotates relative to the worktable 5. The upper end of the writing drum 1 is driven to rotate by the servo motor 203 in the drum power mechanism 2, and the upper end edge of the writing drum 1 A plurality of test sockets 104 are evenly distributed along the circumferential direction. The mechanical gripper 3 has multiple groups of grippers that can move back and forth. The test socket 104 rotates with the writing drum 1 to the unclamping station where the clamping mechanism 4 is located. Any set of grippers will grasp the chips in the test sock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com