A handleless filter gate valve

A filter gate and filter screen technology, applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of difficult integration of filter functions, difficult installation of gate valves, insufficient appearance, etc., and achieve the effect of simple and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

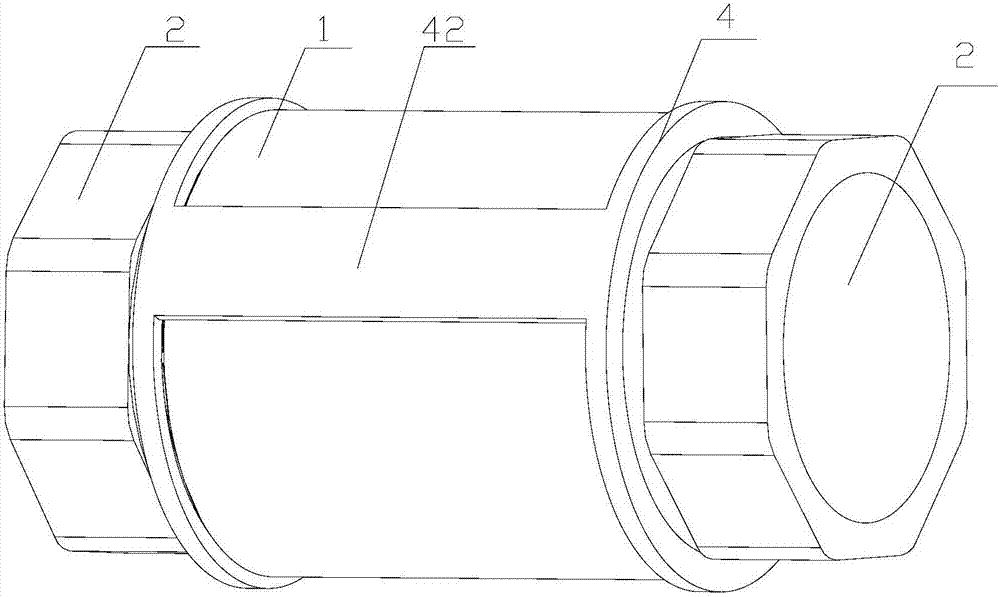

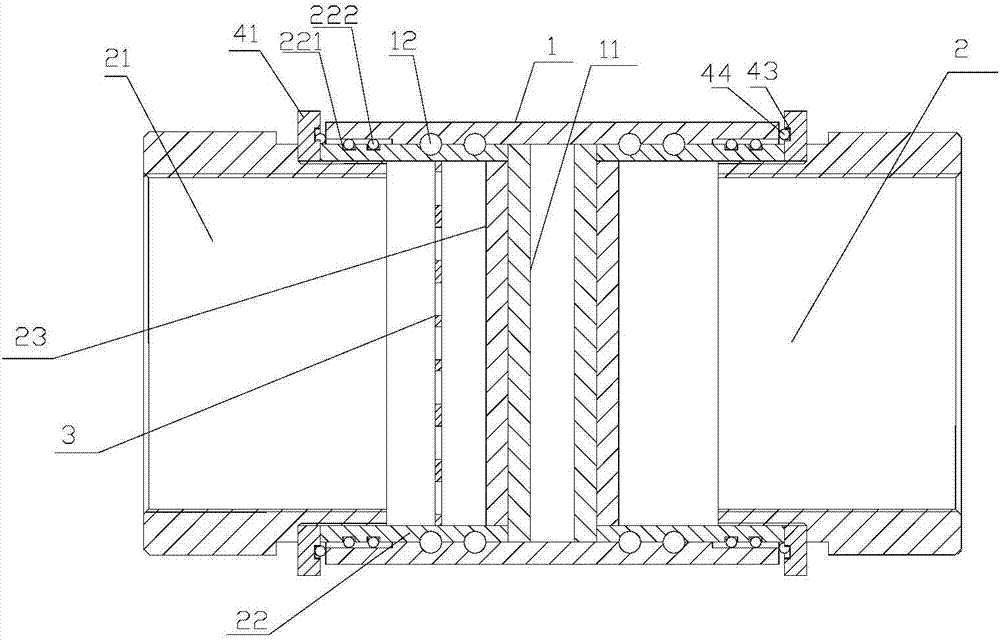

[0016] Embodiment 1 A sessless filter gate valve according to the present invention includes a rotary shell 1, a valve core 2 for connecting pipelines and a filter screen 3, and the inner cavity of the rotary shell 1 is equipped with two rotary The baffle 11, the rotary baffle 11 is provided with through holes or gaps; the ends of the rotary housing 1 are each equipped with a valve core 2; the valve core 2 includes a The connection port 21 at the end of the road, the fixed sleeve 22 and the fixed baffle 23, the connection port 21 is screwed to the fixed sleeve 22; the fixed sleeve 22 is sealed and inserted into the rotary The end of the housing 1; the fixed baffle 23 is sealed and installed on the inner end surface of the fixed sleeve 1, and the end surface of the fixed baffle 23 is sealed with the end surface of the rotary baffle 11 on the same side Fitting; the edge of the filter screen 3 is affixed to the inner wall of the fixed sleeve 22; the through hole or gap on the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com