One-stop production process of wood-rod pencil

A production process and pencil technology, applied in the direction of non-active pencils, printing, writing utensils, etc., can solve the problems of short delivery time, inestimable losses, and inability to respond to short, flat and fast demands, so as to avoid loss and loss, simplify intermediate steps, Satisfy the effect of multiple varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

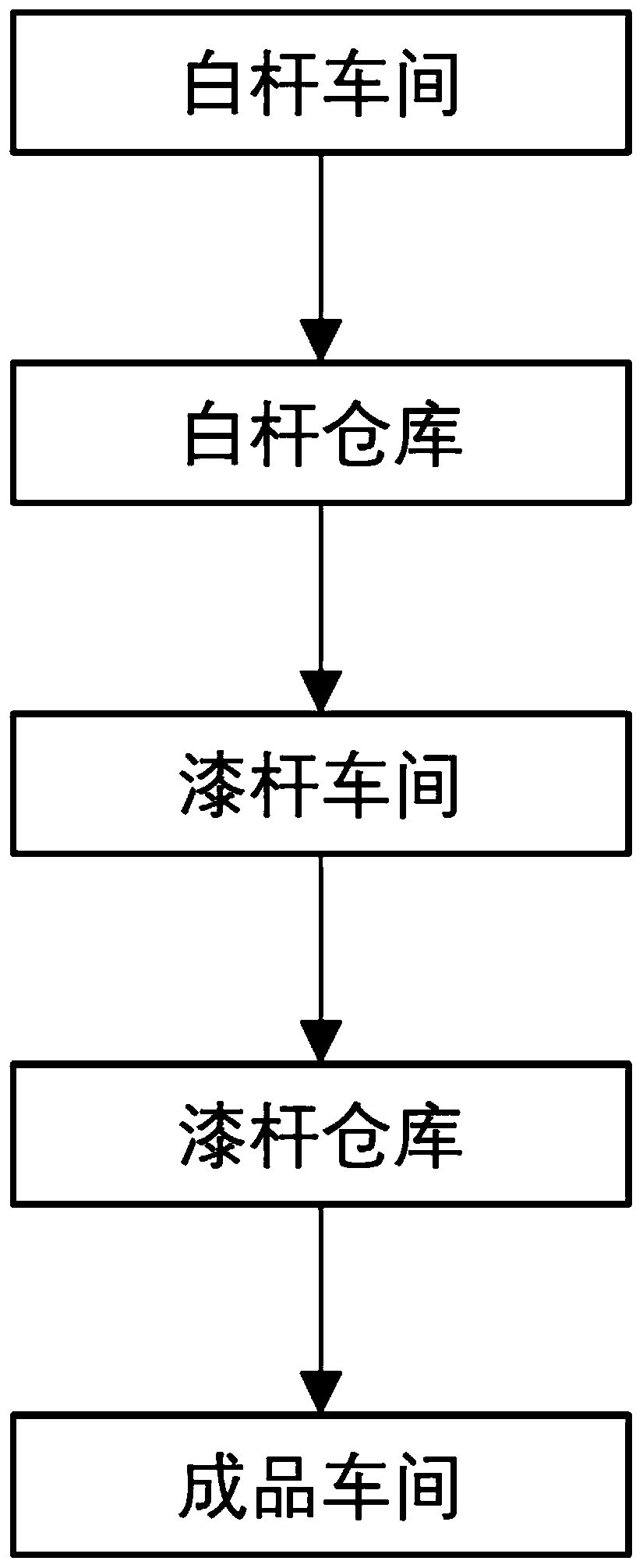

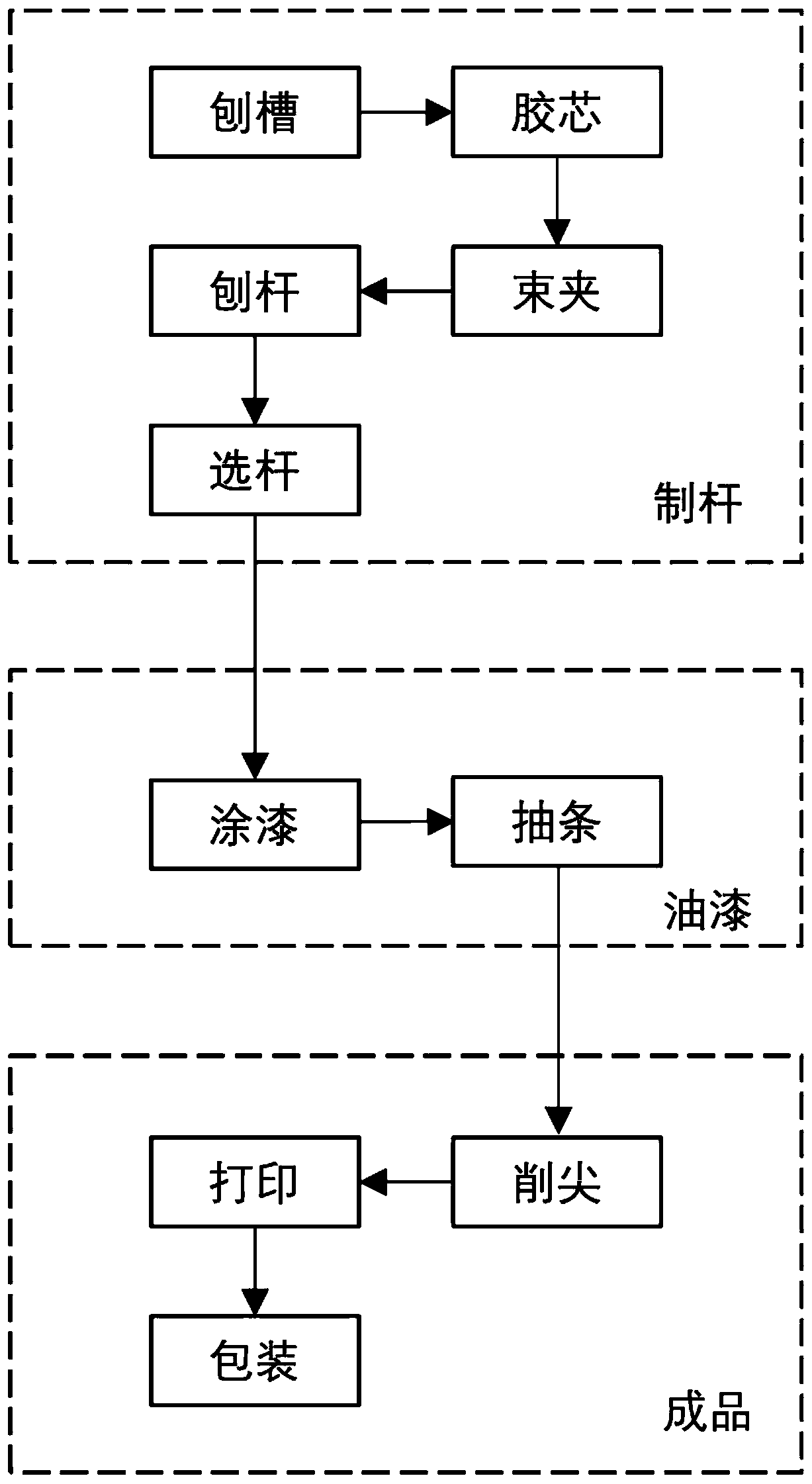

[0015] The invention provides a one-stop production process of wooden pencils, which adopts pull-type production, no longer sets up workshops according to the procedures, but merges all procedures into one production line, completes all procedures in one workshop, and completes all procedures in the pull-type production line. In production, the latter operation is required to process as many products as needed, and the previous operation is required to manufacture just the required semi-finished products / parts, and there is no semi-finished product inventory, that is, the production plan is to place customer orders directly to the production line instead of dismantling customer orders It is divided into semi-finished products and distributed to each production workshop.

[0016] Such as figure 2 As shown, the one-stop production process of the wooden pencil includes the rod making process, the painting process, and the finished product process. The three processes are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com