Multi-screw-edge structure screw rod

A technology of screw and flight, applied in the field of multi-flight structure screw, to achieve the effect of enhancing mixing capacity and promoting air discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

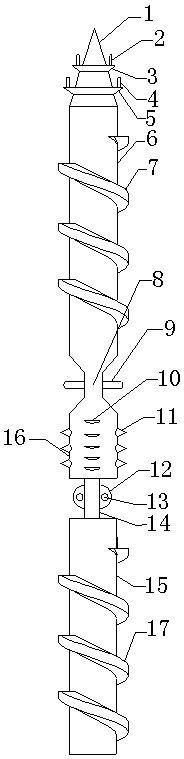

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The multi-flight structure screw of the present invention comprises a screw head 1, a stirring column 2, an obstacle ring 3, a stirring column 2 4, an obstacle ring 5, a screw body 6, a screw edge 7, a screw body 2 8, and a horizontal stirring Column 9, short edge 10, tapered edge 11, ear edge 12, hemispherical body protrusion 13, screw body four 14, screw body five 15, screw body three 16 and screw edge two 17, the screw head 1 is provided with Screw body one 6, the bottom of screw body one 6 is screw body two 8, the bottom of screw body two 8 is screw body three 16, the bottom of screw body three 16 is screw body four 14, and the outside of screw head 1 is provided with obstacle ring one 3, the obstacle The ring one 3 is provided with a stirring column one 2, the screw head 1 is provided with an obstacle ring two 5, the obstacle ring two 5 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com