A kind of gear billet mold

A gear mold and gear technology, which is applied to gears, household appliances, and other household appliances, can solve the problems of time-consuming cleaning of saw teeth and breakage, and achieve the effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

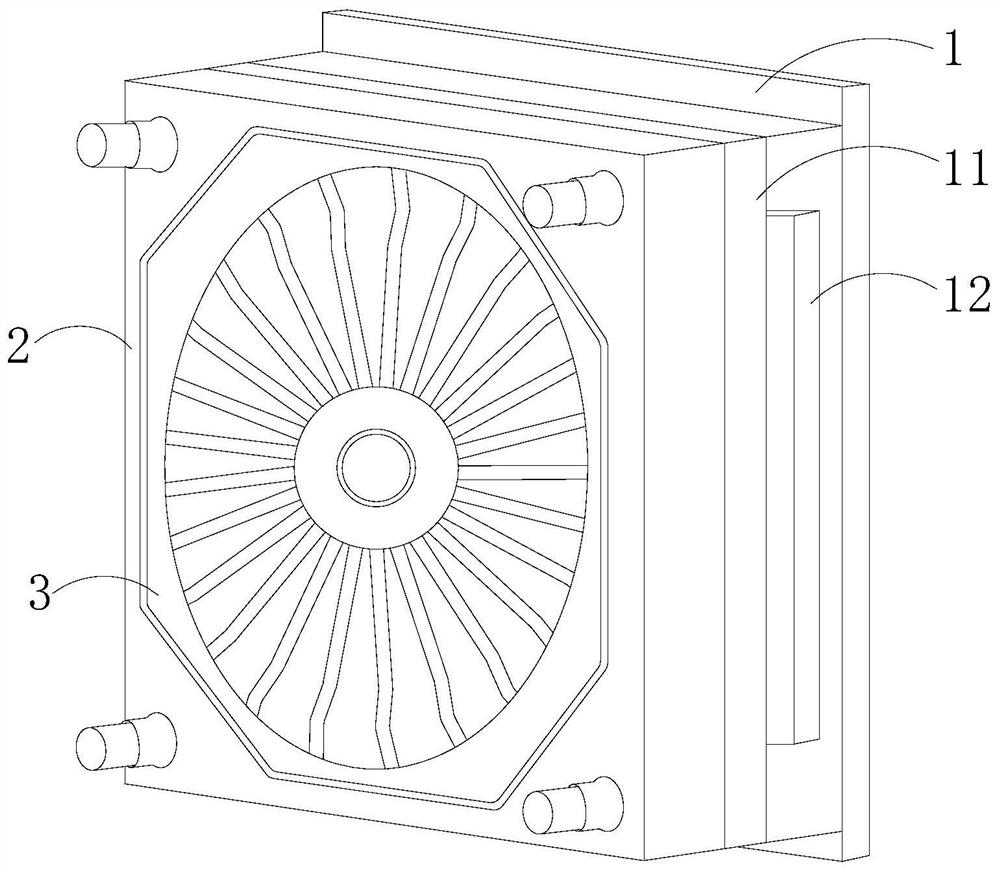

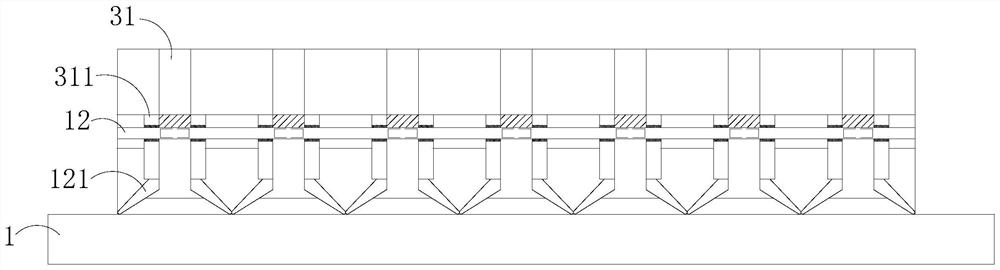

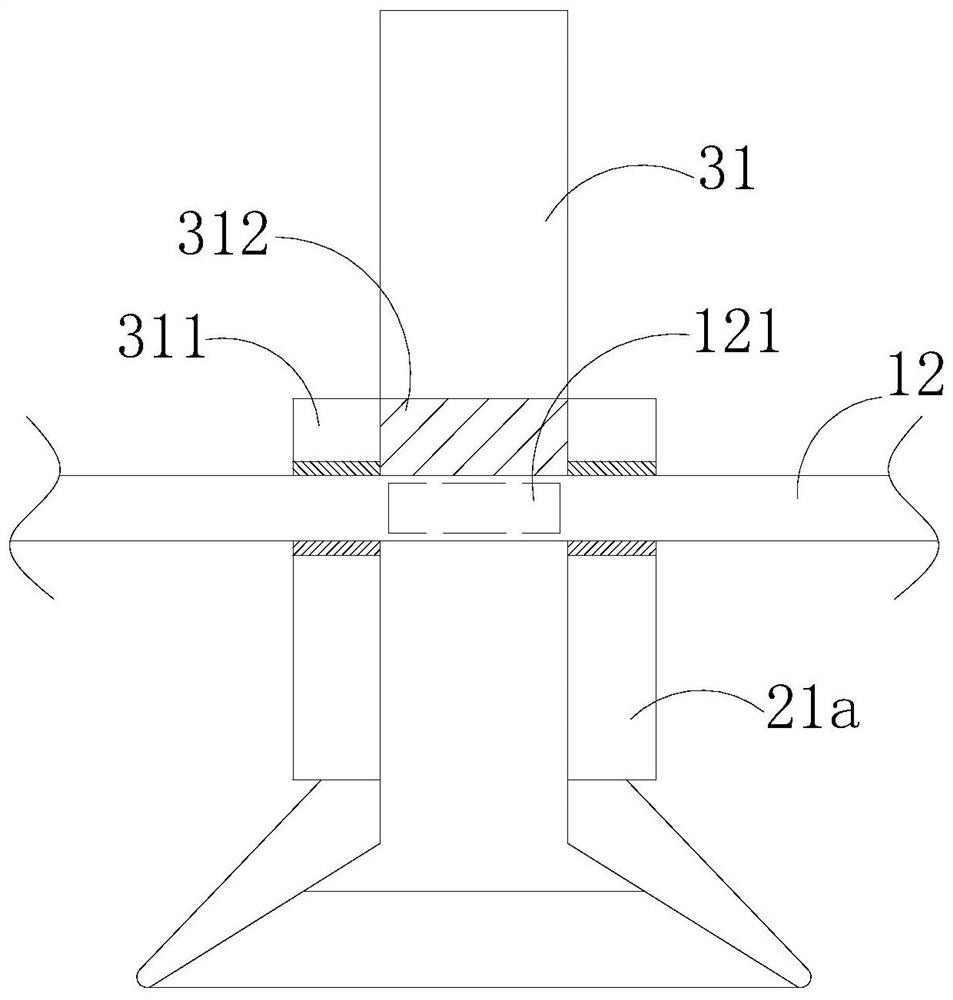

[0031] Such as Figure 1-Figure 6 As shown, the present invention provides a kind of gear billet mold, and its structure comprises bottom mold base 1, bottom mold 2, gear mold 3, and described gear mold 3 is provided with two or more tooth grooves 31, and in described bottom mold 2 is equipped with a gear mold 3, the bottom mold base 1 and the bottom mold 2 are integrated, a side groove 11 and a push rod 12 are arranged between the bottom mold base 1 and the bottom mold 2, and the side The gap fit is adopted between the groove 11 and the push rod 12, the side groove 11 communicates with the cooling groove 311 in the tooth groove 31, and the end of the push rod 12 placed inside the bottom mold 2 is fitted with a limit base 121, The limiting base 121 is provided with a limiting washer 21 a limited to the horizontal axis of the push rod 12 , and the cooling groove 311 wraps the outer surface of the tooth groove 31 .

[0032] The inside of the tooth groove 31 is provided with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com