Solid waste multistage treatment device

A solid waste and processing device technology, applied in the field of waste recycling and processing equipment, can solve the problems of difficult solid waste to be fully broken, low utilization rate of organic matter, low recovery efficiency and quality, etc., so as to facilitate later recycling and professional recycling , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

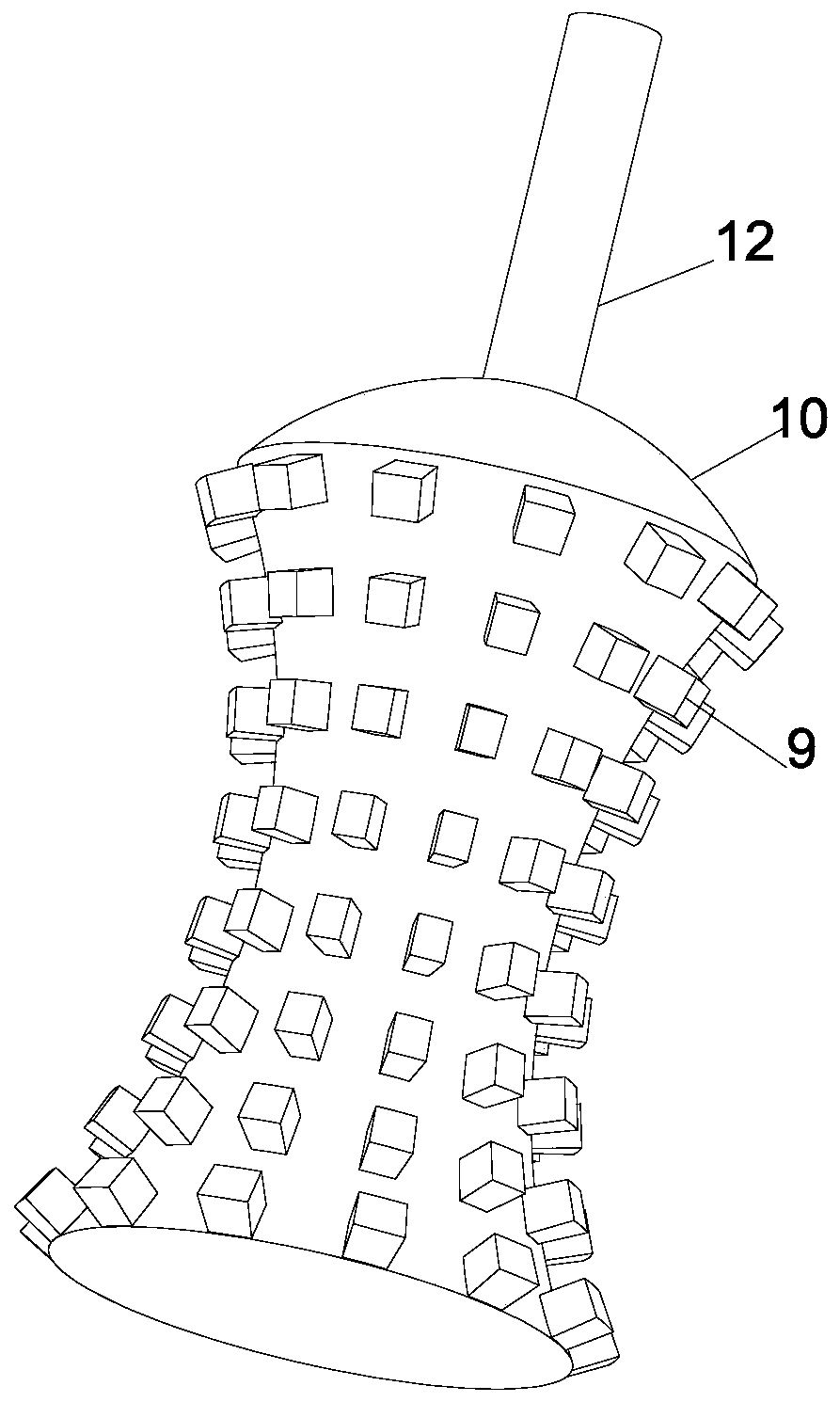

[0024] see Figure 1~4 , in an embodiment of the present invention, a solid waste multi-stage treatment device includes a vertically arranged support installation cylinder 16, a number of support installation columns 7 are arranged at an equal angle at the lower end of the support installation cylinder 16, and the upper half of the support installation cylinder 16 is horizontal An installation partition 14 is provided, and the middle position of the upper end of the installation partition 14 is vertically provided with a drive installation plate 21, the upper end of the drive installation plate 21 is connected with the support installation cylinder 16, and the tops of the support installation cylinder 16 at both ends of the drive installation plate 21 are provided with There is a feeding hole 18, and the middle position of the driving installation plate 21 is horizontally provided with a driving motor 20, and the two ends of the driving motor 20 are symmetrically provided with ...

Embodiment 2

[0027] On the basis of Embodiment 1, the solid waste entering from the feeding hole 18 will not fall into the non-working area by stretching the partition belt 19, so that the continuous and stable operation of the device can be ensured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com