Novel double-layer vacuum cup

A new type of double-layer heat preservation technology, applied in the field of thermos cups, can solve the problems of reduced function and life, immature processing technology, and discounted effects, etc., and achieve good heat preservation effect, good heat absorption storage function, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order for those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

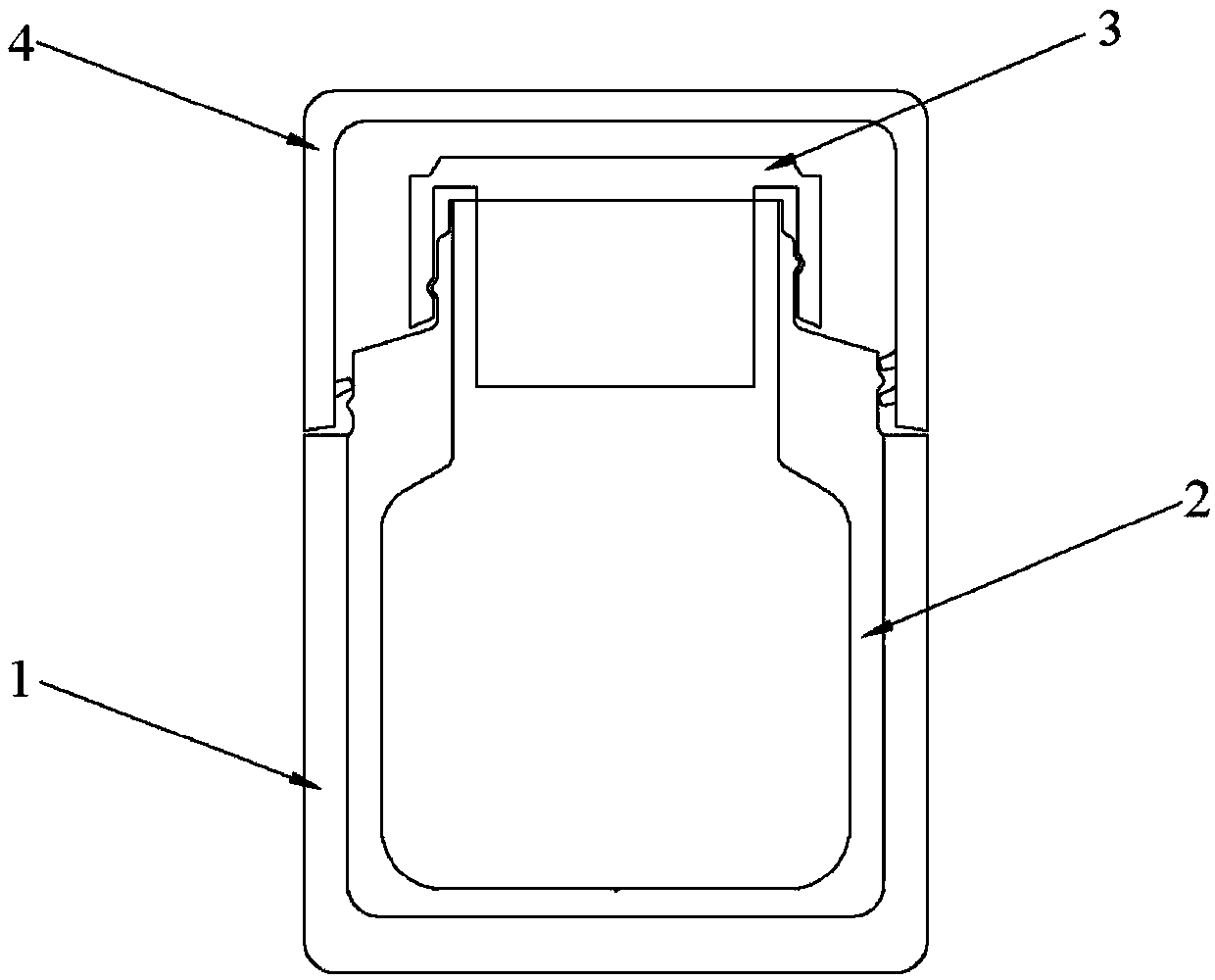

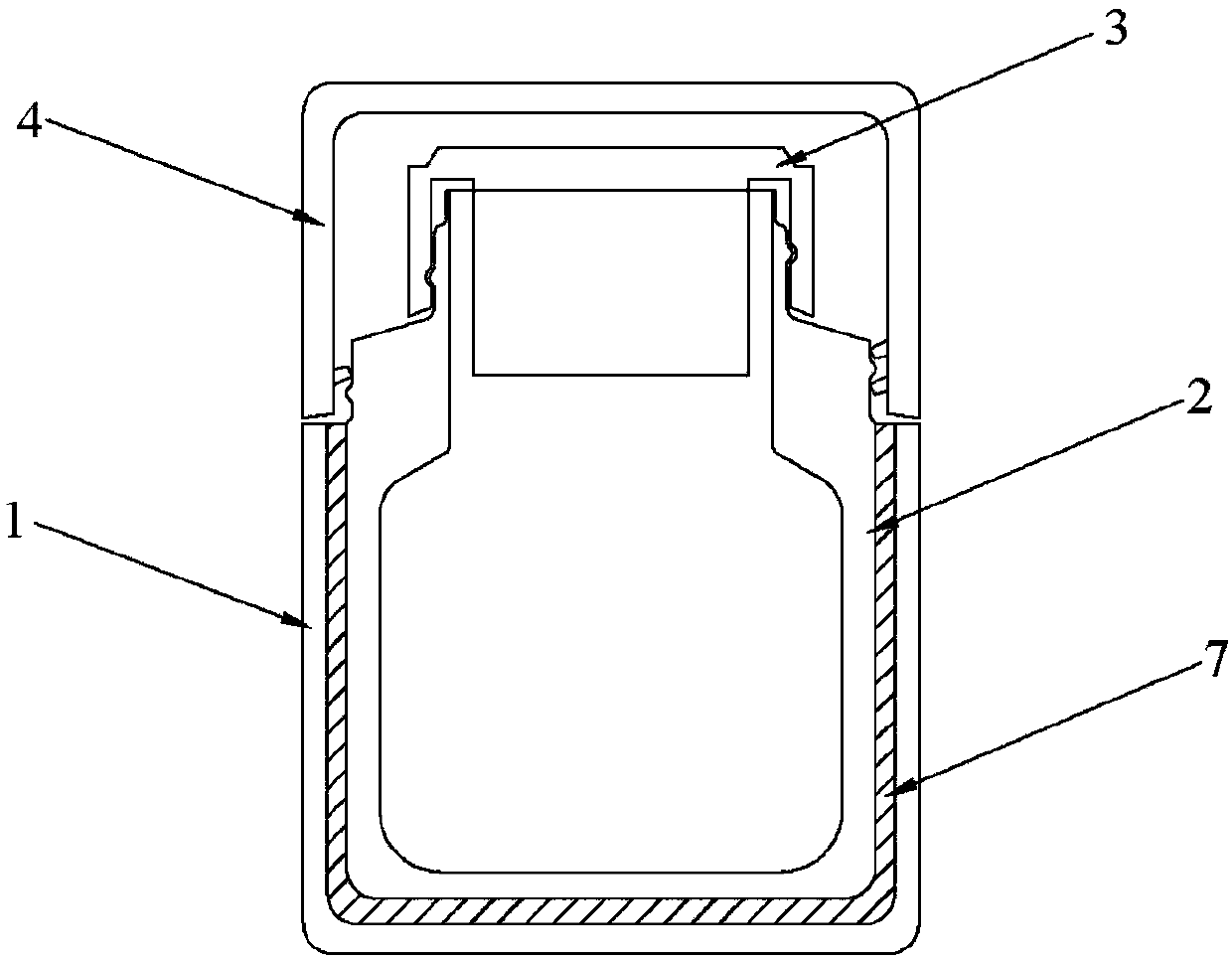

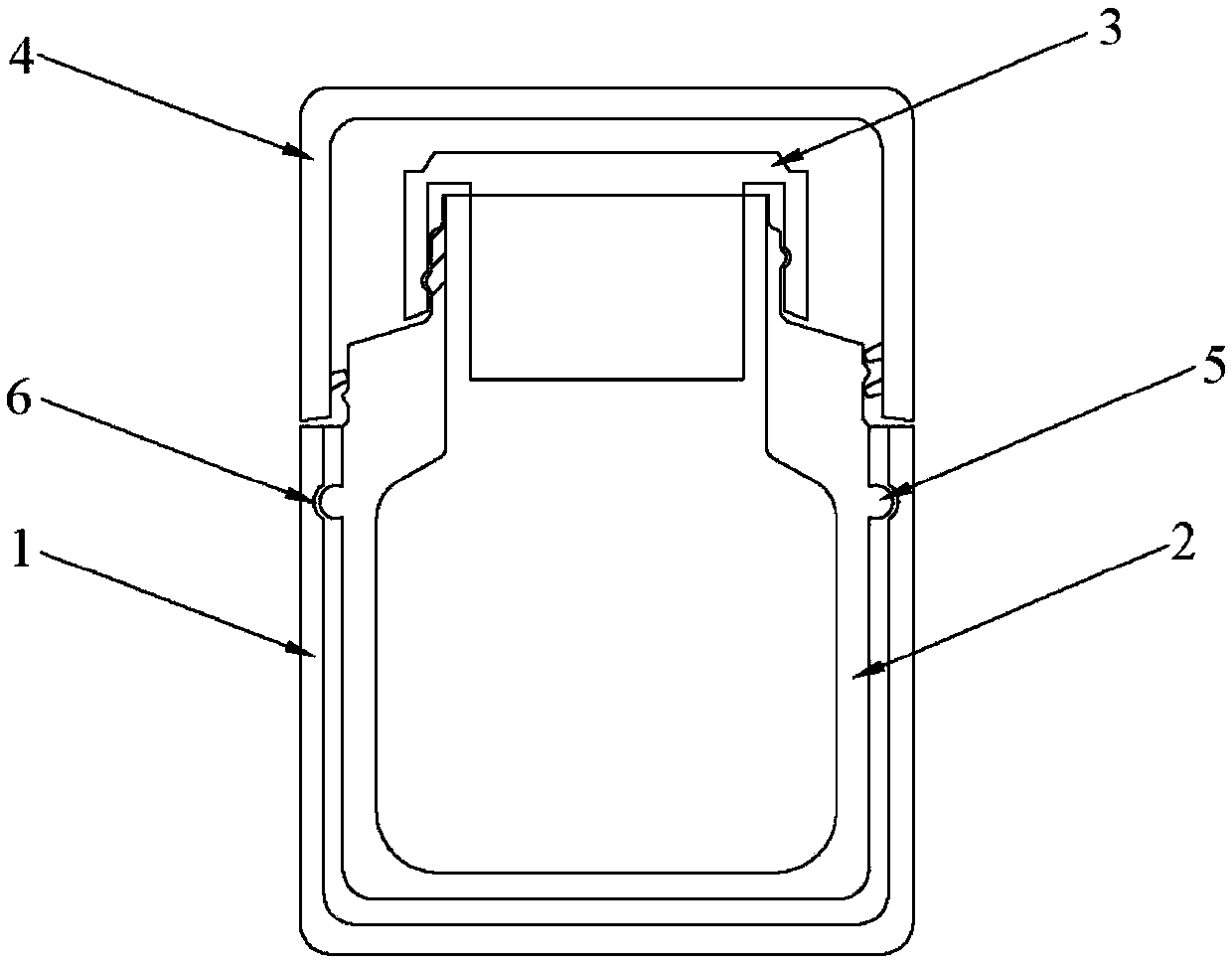

[0022] see Figure 1 to Figure 4 As shown, the present invention provides a novel double-layer thermos cup, comprising a cup body made of a cup wall and a cup cover made of a cover wall, wherein the cup body includes an outer cup body 1 with a whole body vacuum inside the cup wall and The inner cup body 2 with a whole body vacuum inside the cup wall, the cup wall constituting the outer cup body is a phase change material, the inner cup body is wrapped in the outer cup body through its own lower section, and the cup cover includes an inner cup cover 3 and the outer cup lid 4 with a whole-body vacuum inside the cover wall, the inner cup lid is buckled and fastened on the mouth of the inner cup body, and the outer cup lid is tightly fastened on the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com