A connection structure between a hydraulic cylinder piston rod and a load

A connection structure and hydraulic cylinder technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of hydraulic system dynamic performance deterioration, increased clearance, and aggravated mechanism damage, so as to increase stability and reliability, reduce heat, The effect of reducing mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

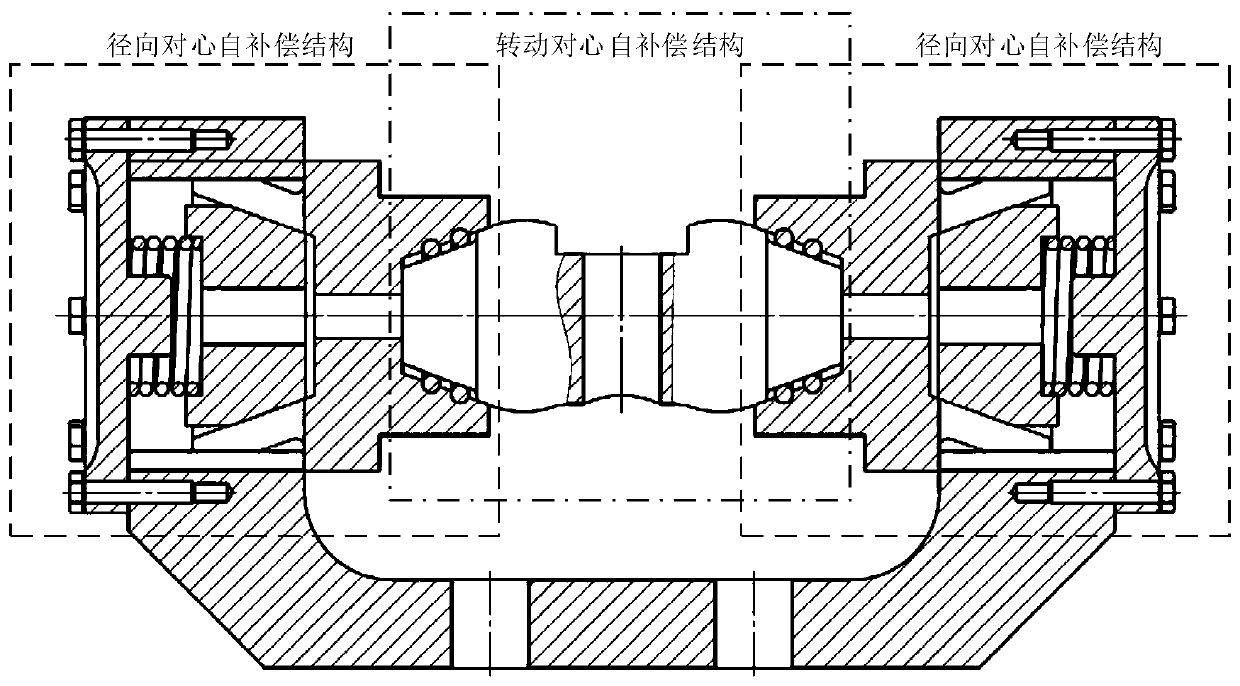

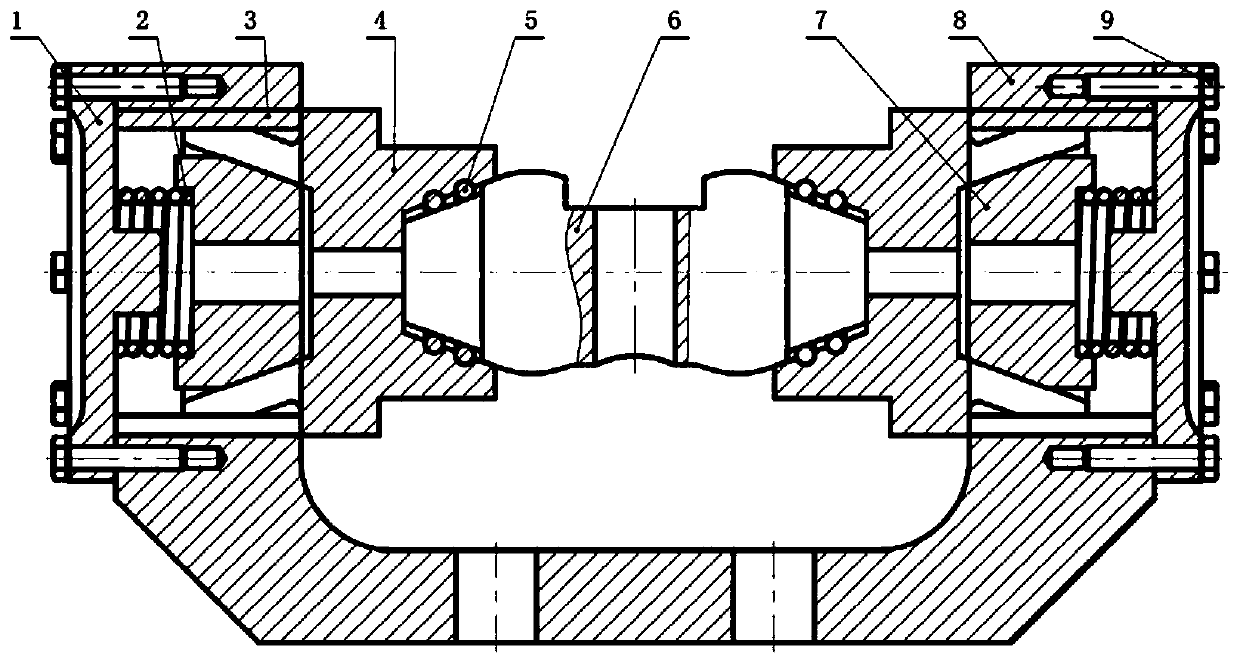

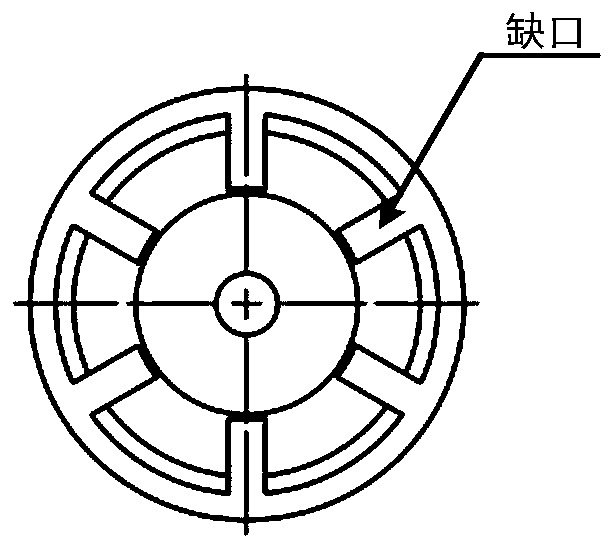

[0016] combine Figure 1~3b , the present invention is mainly composed of two parts: a radial centering self-compensation structure and a steering centering self-compensation structure. The radial centering structure is mainly composed of gland 1, compression spring 2, open bushing 3, self-compensating parts 4, expansion block 7, external parts 8, and hexagonal bolts 9; the steering centering self-compensating structure is mainly composed of self-compensating Part 4, rolling body 5, and hydraulic cylinder connecting shaft 6 are composed. The gland 1 is connected to the external member 8 through eight hexagonal bolts 9 evenly arranged, and the bottom of the external member 8 is arranged with four threaded holes symmetrically distributed to connect with the load end; the compression spring 8 is nested on the gland 1 and tightened by ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com