3D printer monitoring device

A 3D printer and monitoring device technology, applied in the field of 3D printing, can solve the problems of 3D printer equipment failure, lack of operation management, hidden danger of 3D printer service life, etc., and achieve the effect of avoiding equipment failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

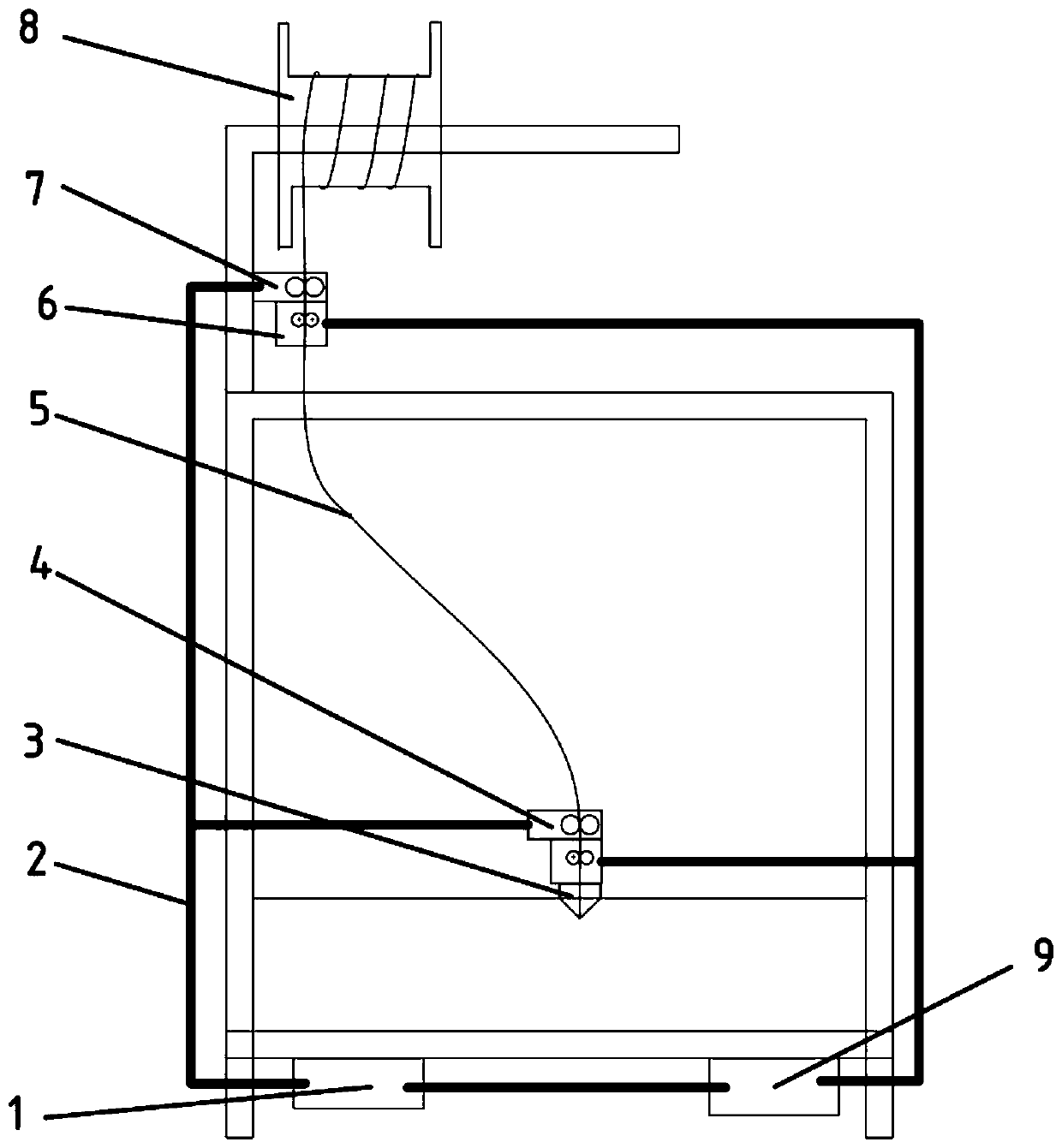

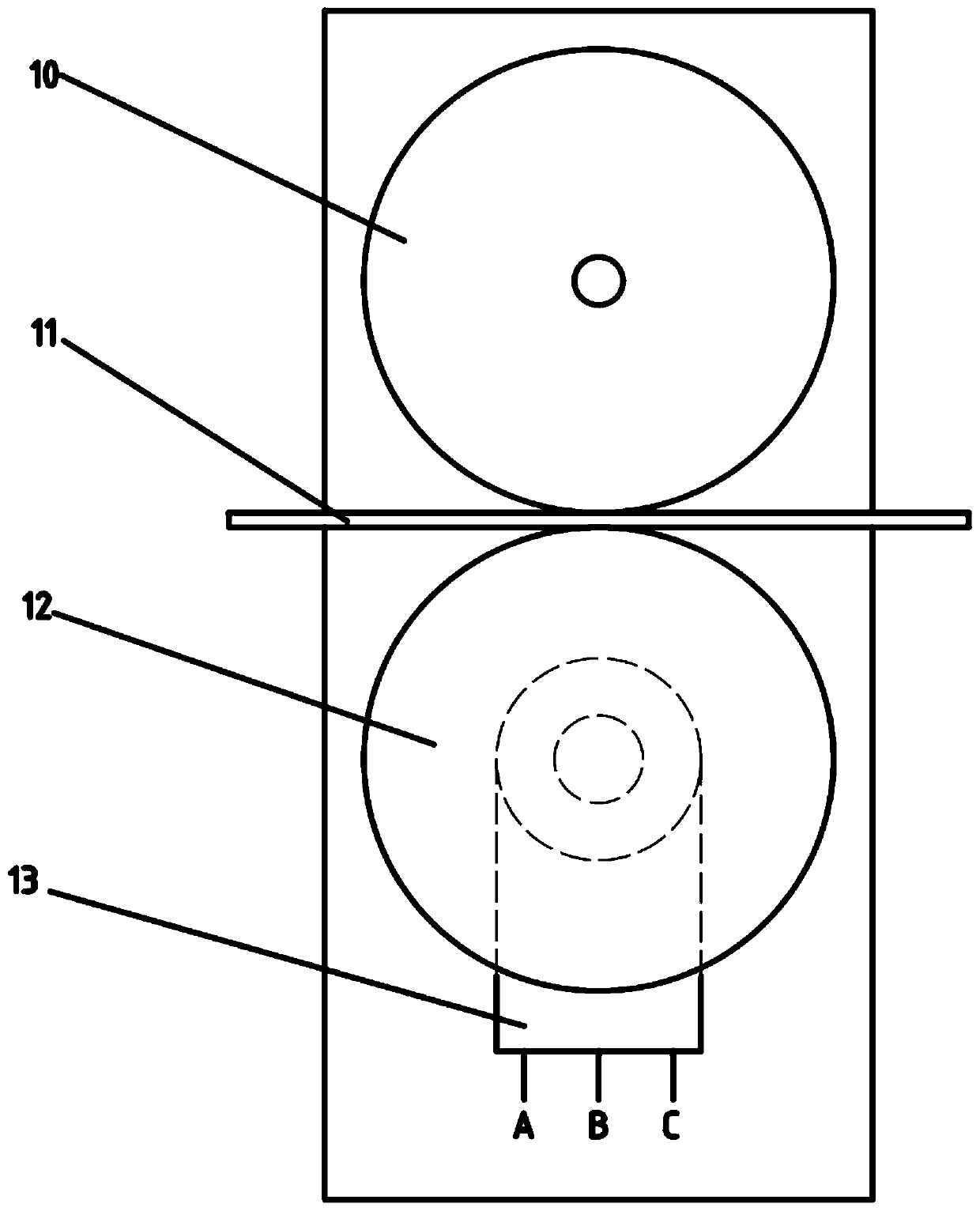

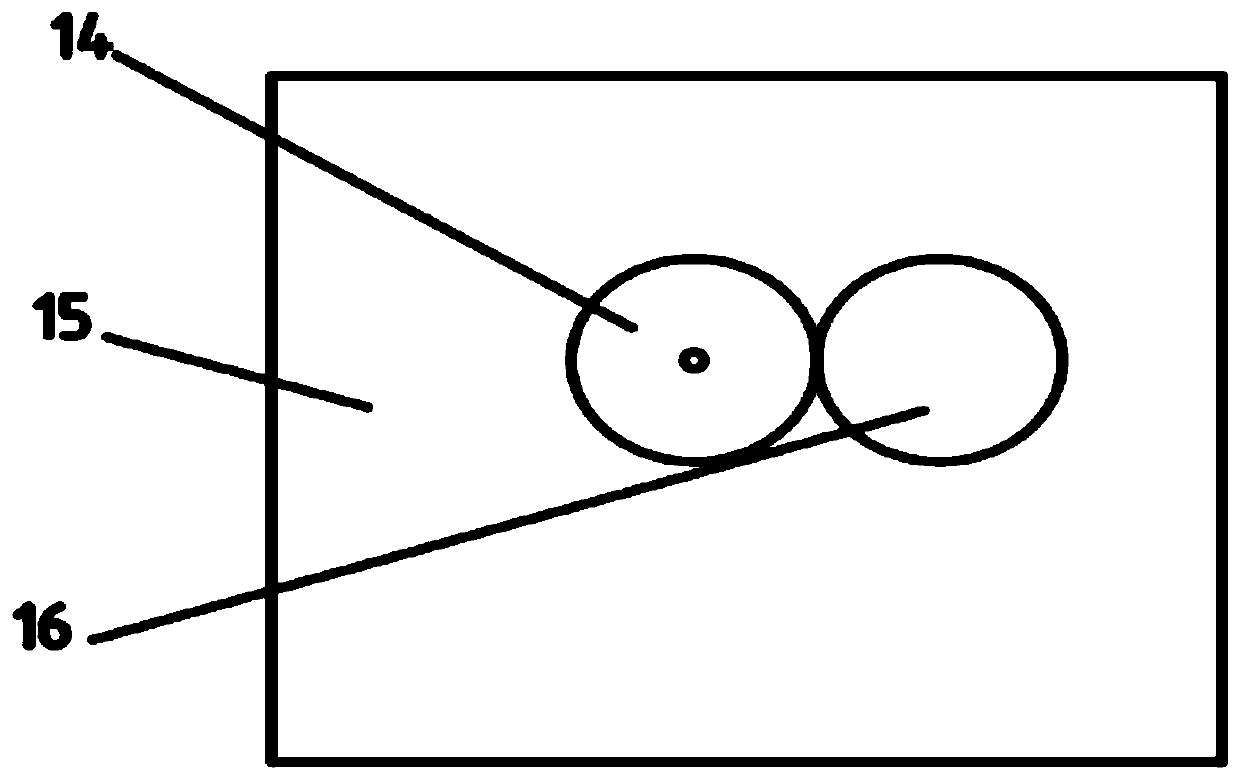

[0022] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , a 3D printer monitoring device, a detector 7, a traction device 6, and a detector 4 are sequentially arranged between a wire tray 8 and an extrusion device 3. The detector 4 / 7 adopts a symmetrical double roller structure, including a driven wheel 10 and a detection roller 12. The detection roller 12 is made of a flexible outer ring with a large friction coefficient, and the wire 5 passes between the two wheels; the detection roller 12 and the Encoder 13 is connected, under normal circumstances, encoder 13 outputs a square wave pulse signal. When the wire feed fails, the wire material 5 will not be conveyed forward, and encoder 13 will stop outputting square waves and become output high / low level. When the counter of the single-chip microcomputer stops working, when the counter stops working within a certain period of time, it can be judged as a wire failure; the encoder 13 is connected to the signal li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com