Stirring barrel for stirring vehicle and stirring vehicle

A mixing drum and mixer truck technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of slow feeding speed, high height of the mixer truck, unfavorable mixer truck registration, etc., and achieve an improvement The effect of increasing the loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

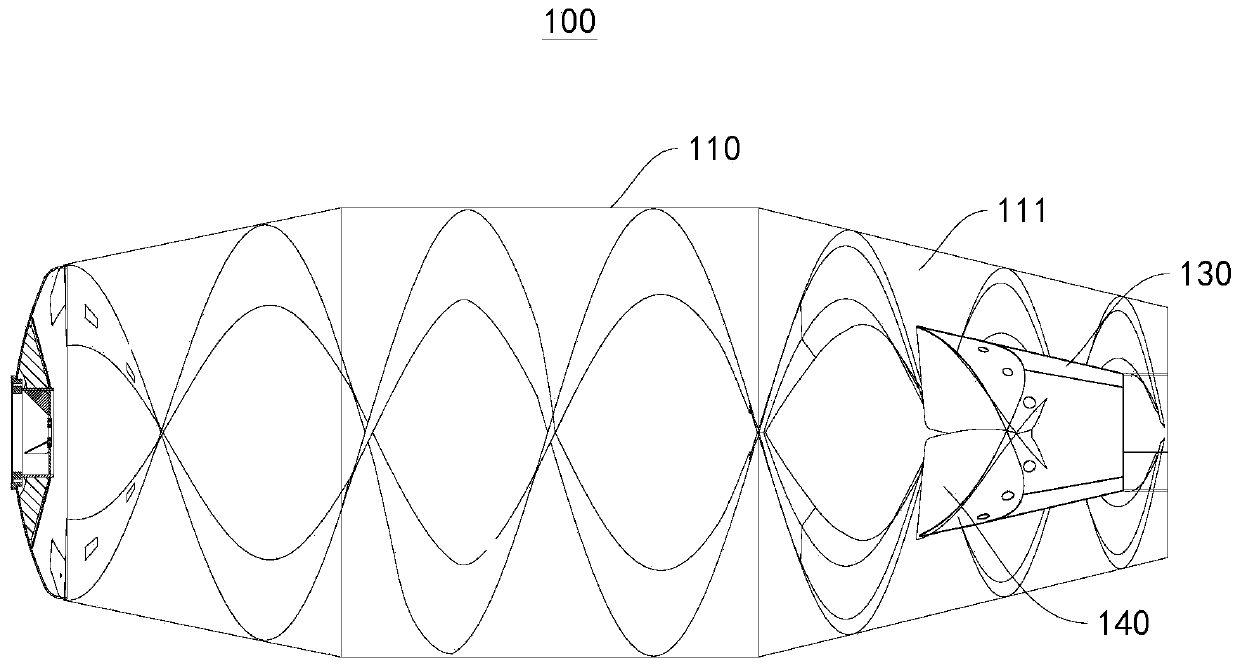

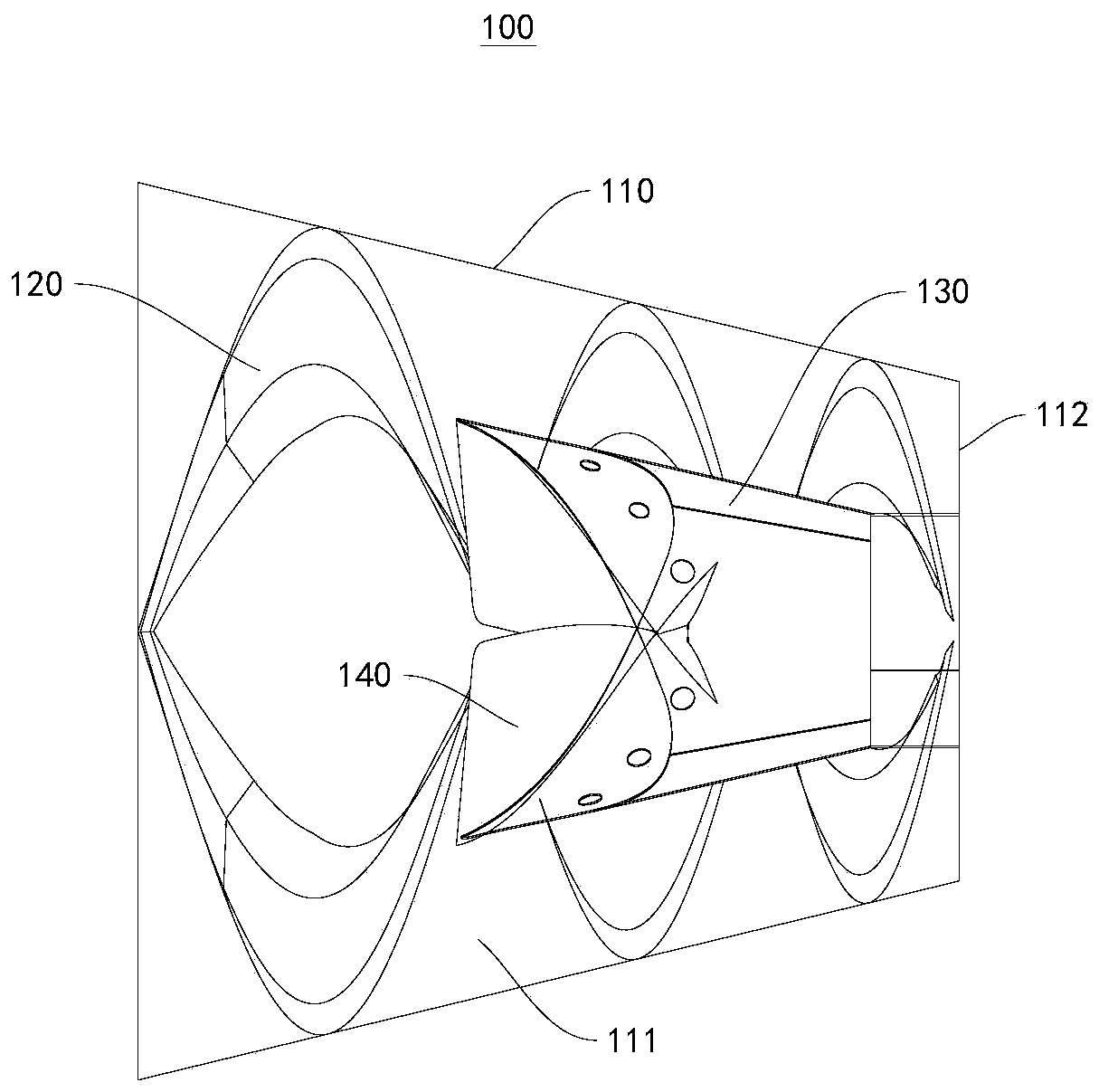

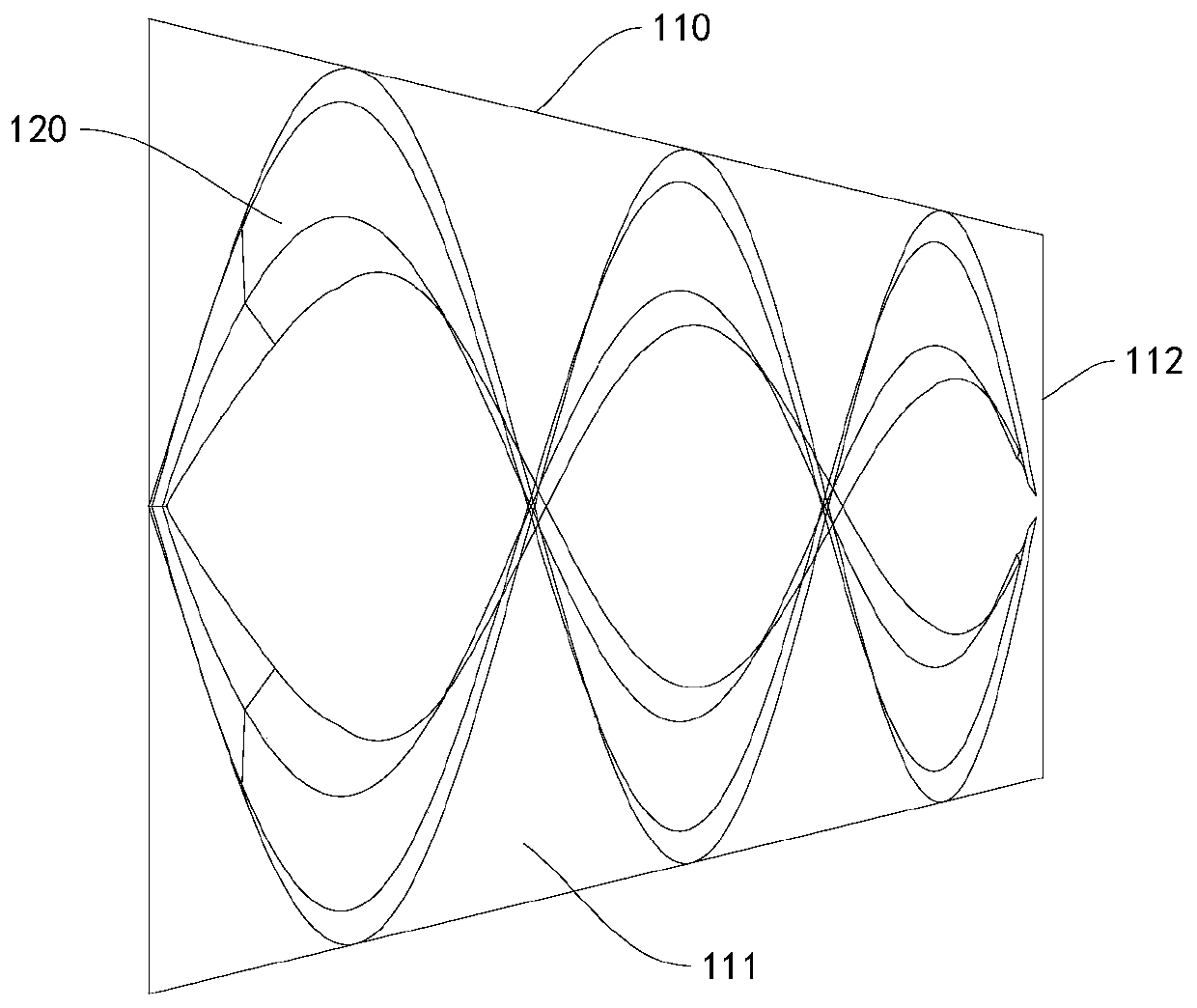

[0033] This embodiment provides a mixing drum 100 for a mixer truck, please refer to figure 1 , figure 2 , image 3 , Figure 4 as well as Figure 5 , comprising a barrel body 110 and a feed cone 130 positioned at the rear end of the barrel body 110, a discharge opening 112 is formed between the inner surface of the rear end of the barrel body 110 and the outer surface of the feed cone 130, and the inner wall of the barrel body 110 is provided with a stirring blade 120 , the inner wall of the small feeding cone 130 is provided with a small cone blade 140 , and the rotation direction of the small cone blade 140 is the same as that of the stirring blade 120 .

[0034] The opening of the feeding small cone 130 rear end is the feed inlet of the mixing drum. Therefore, the structure of the feeding small cone 130 is closely related to the feed rate of the mixing drum. In the technical solution of the present invention, the inner wall of the feeding small cone 130 Small cone bla...

Embodiment 2

[0063] This embodiment provides a mixer truck 200, please refer to Image 6 , this mixer truck 200 includes a chassis and the mixer drum 100 for a mixer truck provided in the first embodiment.

[0064] The chassis is provided with a front assembly and a backstage assembly along the length direction. The front assembly is provided with a reducer 220, and the output shaft of the reducer 220 is connected with the spherical crown 210 of the mixing drum; The rear cone of the vehicle mixer 100 is provided with a raceway 240 that cooperates with the supporting wheel 230 , and the rear cone of the mixer truck 100 is rotatably supported on the background assembly through the cooperation of the supporting wheel 230 and the raceway 240 .

[0065] When working, use the speed reducer 220 to drive the mixing drum to rotate, and the supporting wheel 230 and the raceway 240 cooperate to keep the mixing drum rotating, and due to the existence of the small cone blade 140, the mixer truck 200 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com