Automatic welding device with multi-station rotary disc, and welding method

An automatic welding, multi-station technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of relying on manual operation and cannot realize fully automatic production, and achieve the effect of improving welding quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the protection scope of the present invention.

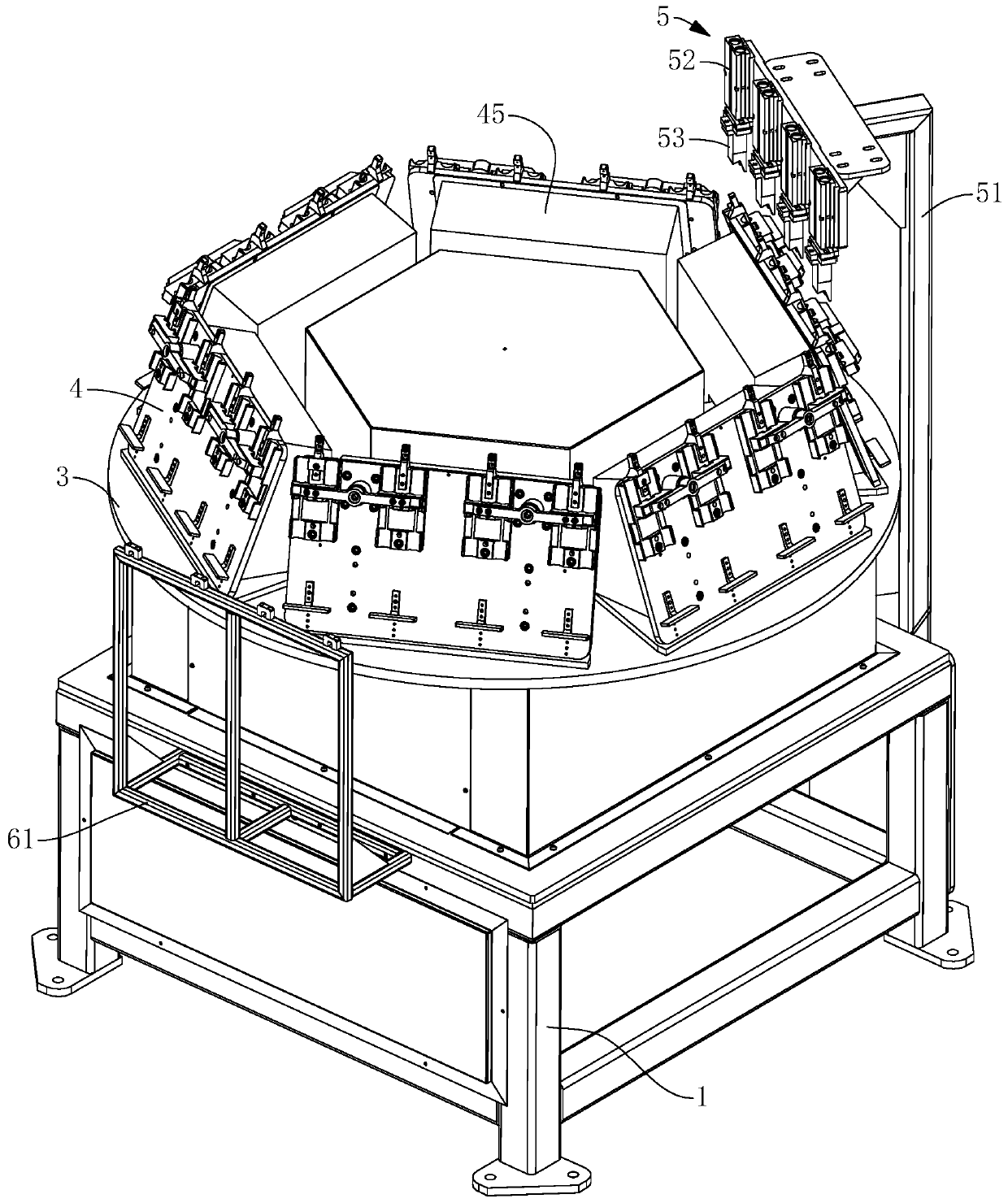

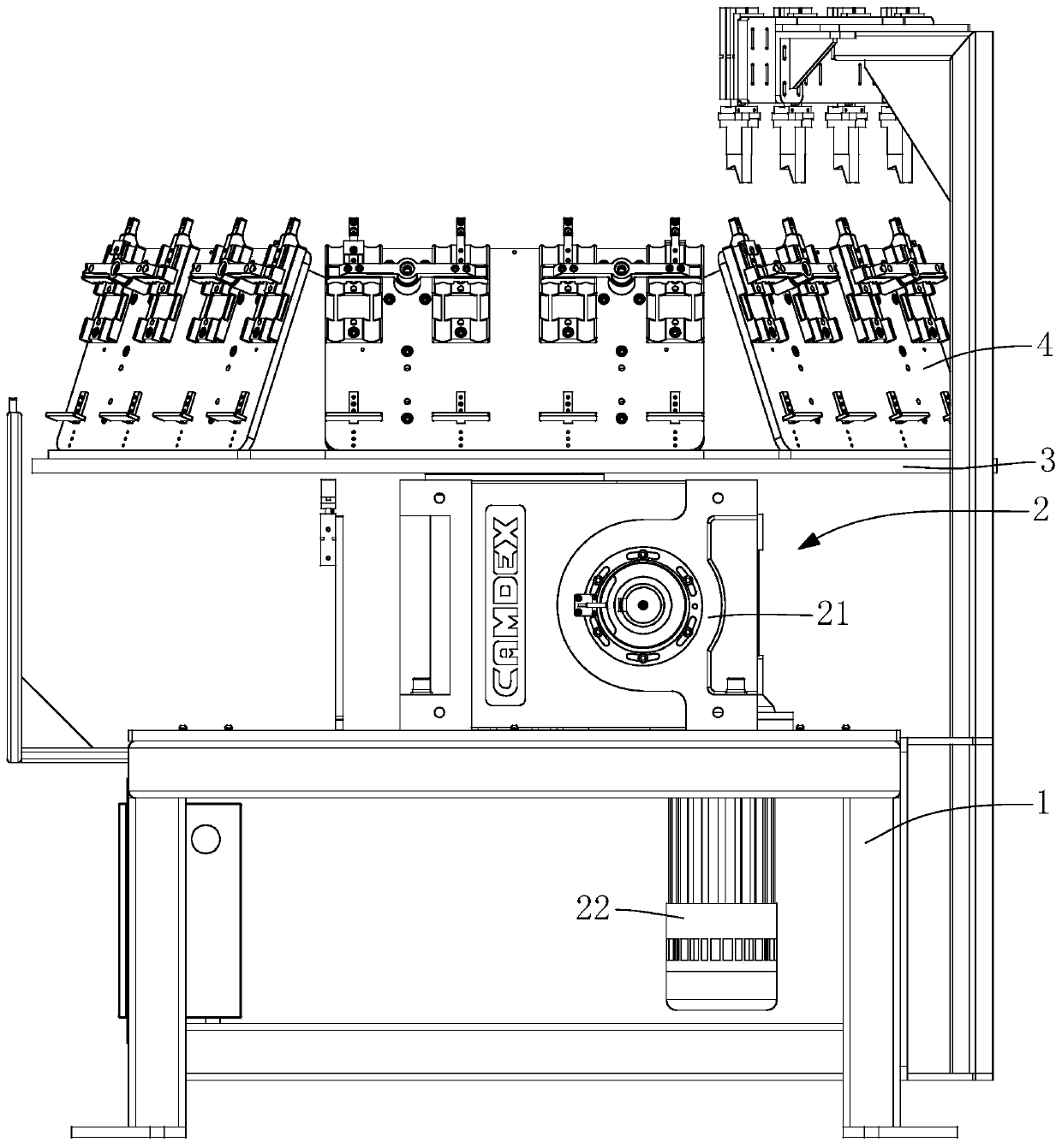

[0025] see Figure 2 to Figure 6 , the present invention provides an automatic welding device with a multi-station turntable, including a base 1, a drive device 2, a turntable 3 and a plurality of workpiece positioning devices 4, the drive device 2 is fixed on the base 1, and the turntable 3 is fixed on the drive device 2 On the output shaft of the turntable 3, the driving device 2 drives the turntable 3 to rotate intermittently, and a plurality of workpiece positioning devices 4 are fixed on the turntable 3 in an annular array, and a feeding station corresponding to each workpiece positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com