Circuit board and formation method of circuit board, and camera module

A technology of camera modules and circuit boards, applied in the direction of cameras, printed circuits, printed circuits, etc., can solve the problems of power increase, affecting the service life of mobile phone cameras, unstable picture quality, etc., and achieve the effect of avoiding imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings.

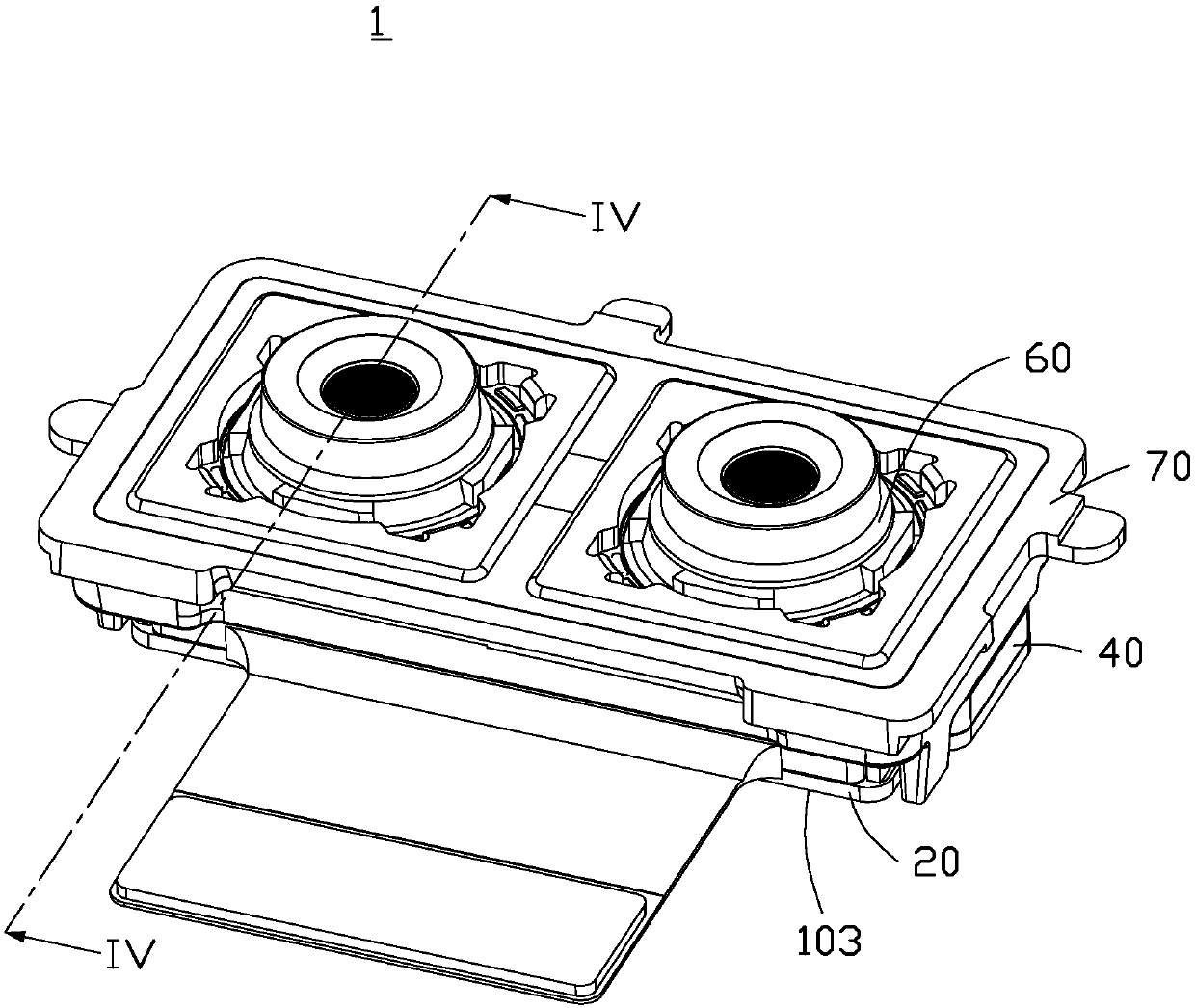

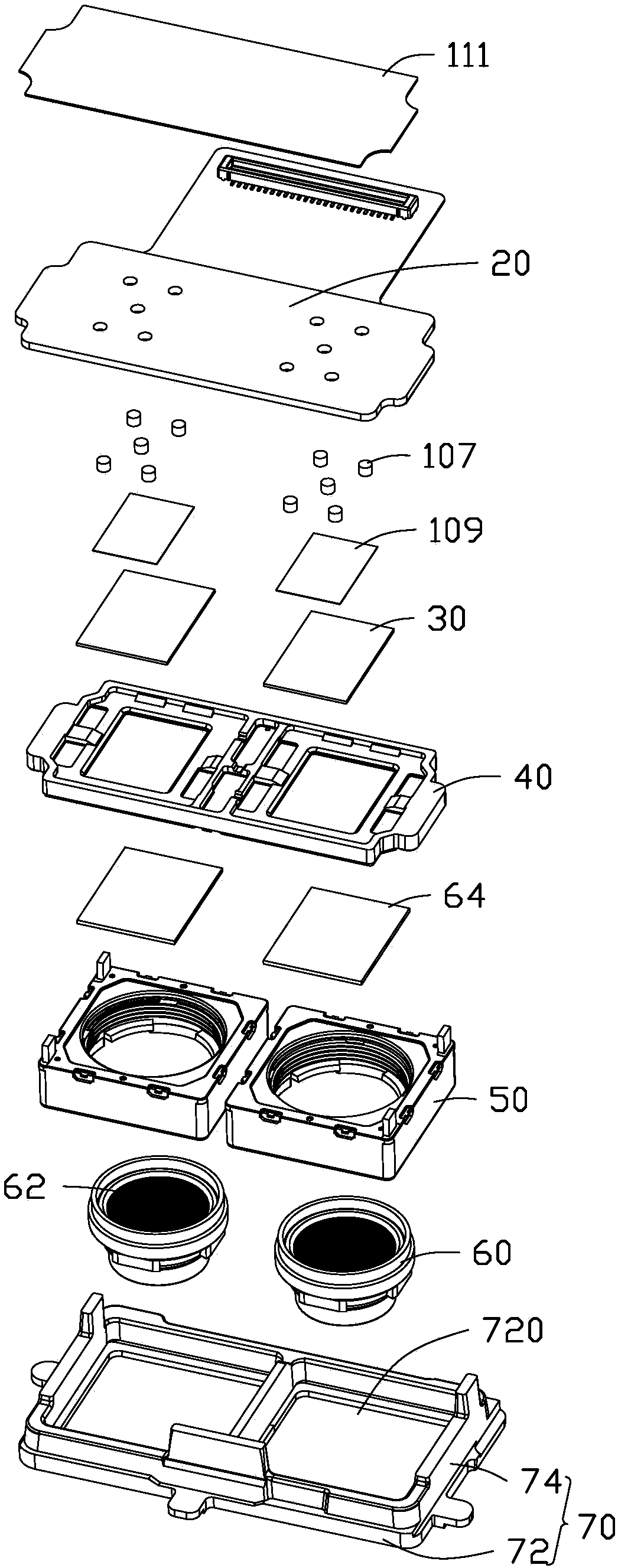

[0035] see Figure 1-4 , a camera module 1 provided in the first embodiment of the present invention. figure 1 The auto-focus dual-lens module is used as an example for illustration, and it can be understood that the technical solution of the present invention can also be used for a fixed-focus module and an auto-focus single-lens module.

[0036] The camera module 1 includes a circuit board 20, an image sensor 30 electrically connected to the circuit board 20, a base 40 disposed on the circuit board 20, and a base 40 disposed on the base. The lens holder 50 , the lens module 60 and the upper cover bracket 70 accommodated in the lens holder 50 .

[0037] see figure 2 and image 3 , the circuit board 20 includes a wiring area 101 and a heat dissipation area 103 inside the wiring area 101 . In this embodiment, the wiring area 101 is electrically insulated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com