A kind of composite corrosion inhibitor and its alkaline electrolyte and aluminum-air battery added with the composite corrosion inhibitor

A composite corrosion inhibitor and electrolyte technology, applied in the directions of alkaline electrolyte, composite electrolyte, aqueous electrolyte, etc., can solve the problems such as the need to further improve the anode efficiency, the complex composition of the composite corrosion inhibitor, and the reduction of the anode corrosion rate. , to achieve the effect of facilitating large-scale popularization and application, reducing hydrogen evolution self-corrosion rate, and improving anode efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

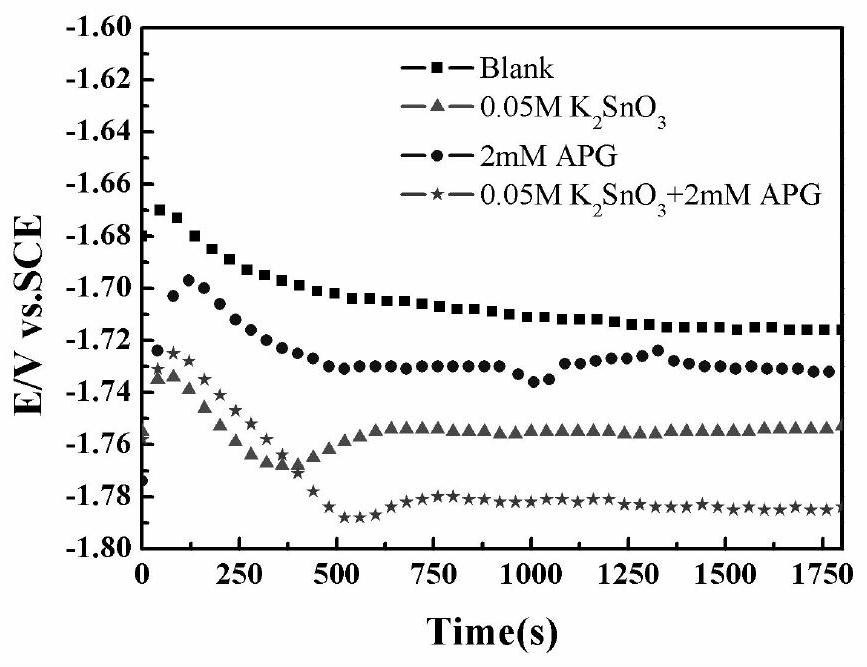

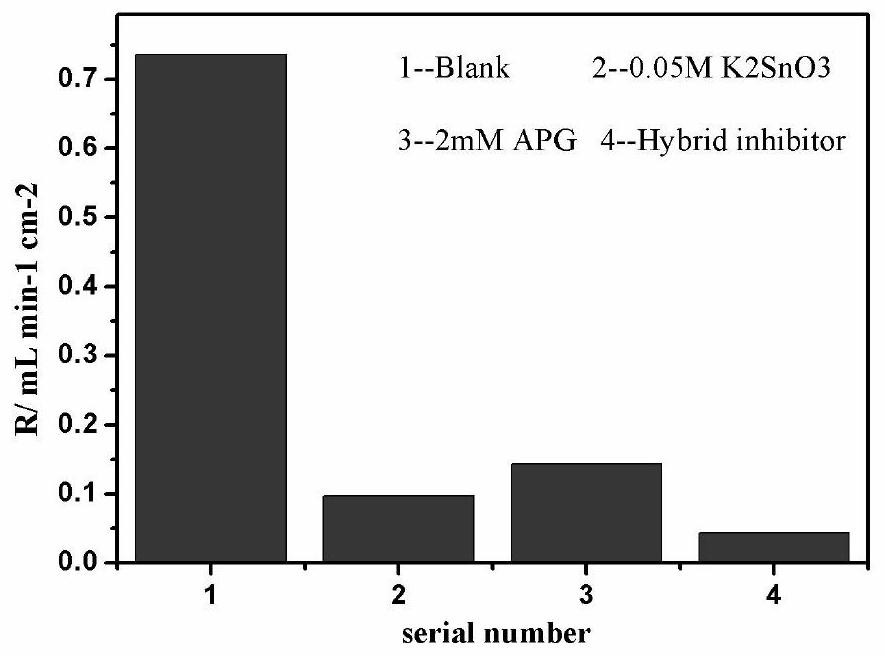

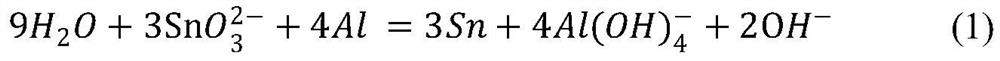

[0046] The electrolyte composite corrosion inhibitor of this embodiment is composed of potassium stannate and aminoglycoside; wherein the molar ratio of potassium stannate and aminoglycoside APG0810 is 25:1.

[0047] The aluminum-air battery electrolyte of the present embodiment includes KOH, potassium stannate, alkyl glycoside, and water; the concentration of alkyl glycoside in the electrolyte is 2mmol / L, the concentration of potassium stannate is 0.05mol / L, and the concentration of KOH is 5mol / L.

[0048] The preparation method of the aluminum-air battery electrolyte of the present embodiment comprises the following steps:

[0049] Preparation concentration is the potassium hydroxide solution of 5mol / L, cools down to room temperature, then adds the potassium stannate of formula quantity in potassium hydroxide solution, stirs, dissolves completely; Potassium in potassium hydroxide solution, stirring to dissolve.

[0050] The aluminum-air battery of this embodiment uses the ...

Embodiment 2

[0052] The electrolyte composite corrosion inhibitor of this embodiment is composed of potassium stannate and alkyl glycoside; wherein the molar ratio of potassium stannate and alkyl glycoside APG0810 is 500:8.

[0053] The aluminum-air battery electrolyte of this embodiment includes KOH, alkyl glycosides, potassium stannate, and water; the concentration of alkyl glycosides in the electrolyte is 0.8mmol / L, the concentration of potassium stannate is 0.05mol / L, KOH The concentration is 5mol / L.

[0054] The preparation method of the aluminum-air battery electrolyte of the present embodiment comprises the following steps:

[0055] Preparation concentration is the potassium hydroxide solution of 5mol / L, cools down to room temperature, then adds the potassium stannate of formula quantity in potassium hydroxide solution, stirs, dissolves completely; Potassium in potassium hydroxide solution, stirring to dissolve.

[0056] The aluminum-air battery of this embodiment uses the above-m...

Embodiment 3

[0058] The electrolyte composite corrosion inhibitor of this embodiment is composed of potassium stannate and alkyl glycoside; wherein the molar ratio of potassium stannate and alkyl glycoside APG1214 is 70:1.

[0059] The aluminum-air battery electrolyte of the present embodiment includes KOH, potassium stannate, alkyl glycoside and water; the concentration of alkyl glycoside in the electrolyte is 1mmol / L, the concentration of potassium stannate is 0.07mol / L, and the concentration of KOH The concentration is 6mol / L.

[0060] The preparation method of the aluminum-air battery electrolyte of the present embodiment comprises the following steps:

[0061] The preparation concentration is the potassium hydroxide solution of 6mol / L, cools down to room temperature, then adds the alkyl glucoside of formula quantity in potassium hydroxide solution, stirs, dissolves completely; In the potassium hydroxide solution of the glycoside, stir to dissolve.

[0062] The aluminum-air battery o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com