Method and system for inspecting wafer defects

A wafer and defect technology, applied in the field of wafer inspection, can solve the problem that the wafer cannot accurately record the location of defects, etc., and achieve the effects of quick reference, high degree of visualization, and easy analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

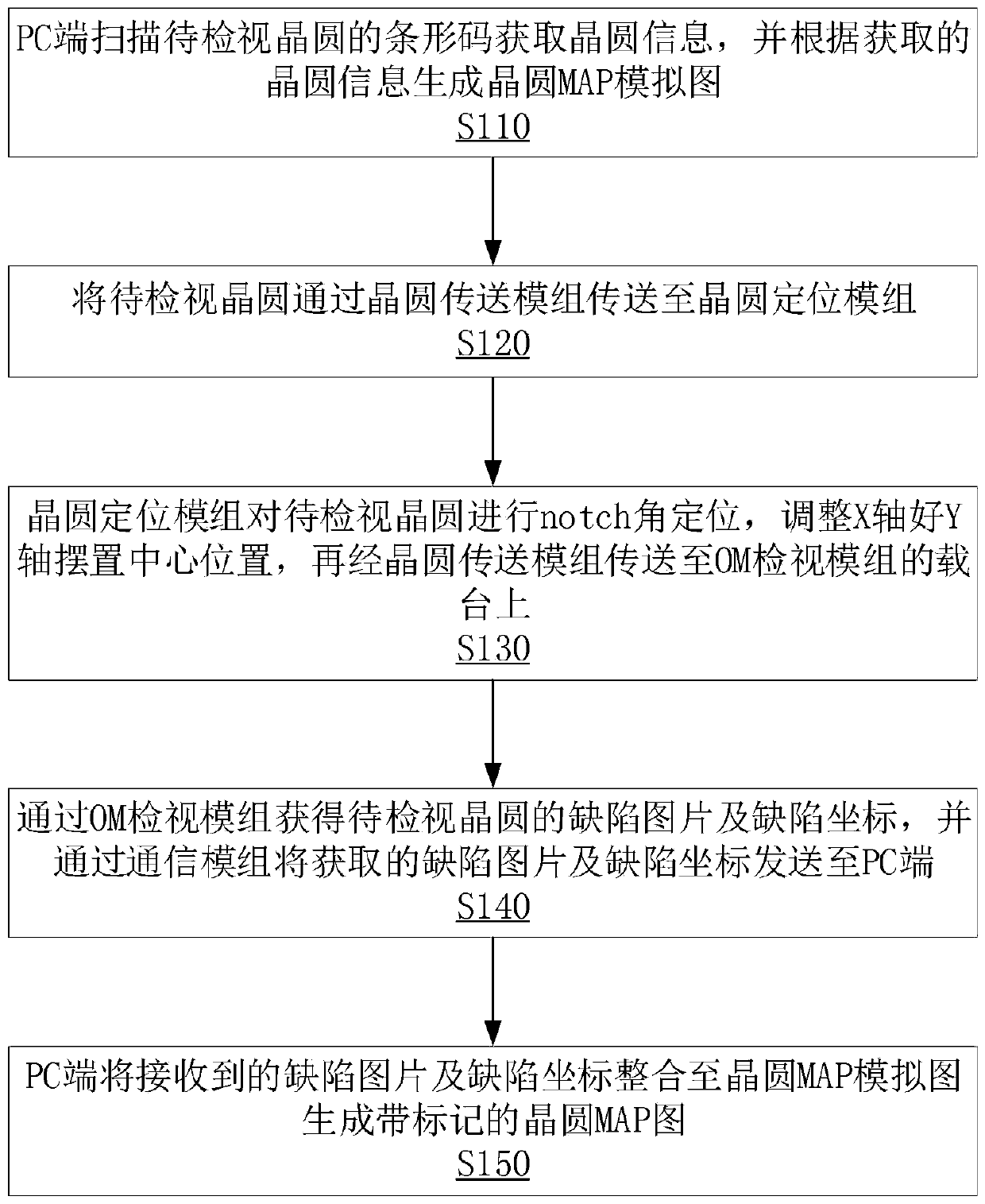

[0042] see figure 1 The method for inspecting wafer defects described in this embodiment includes the following steps:

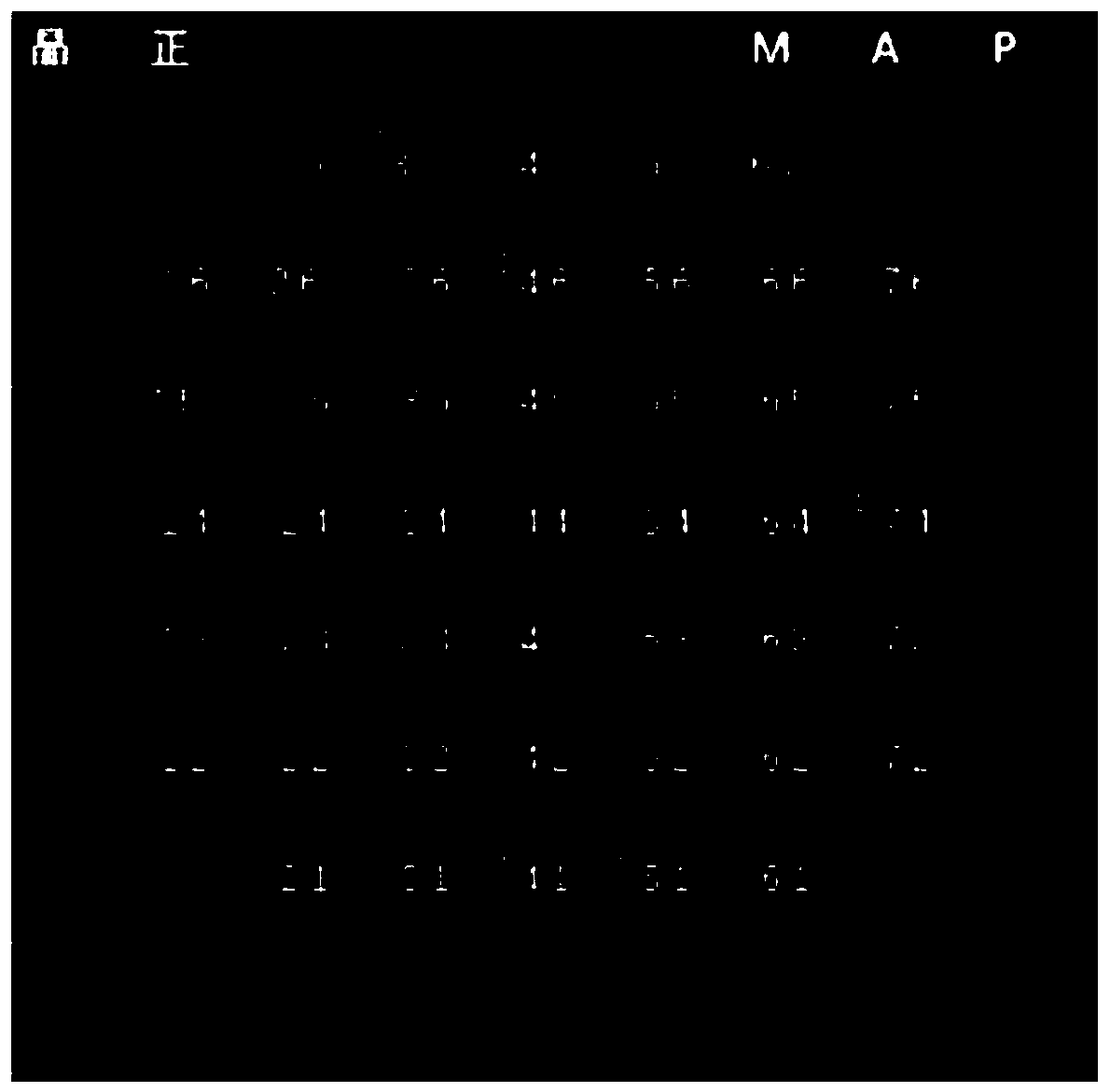

[0043] Step S110: The PC scans the barcode of the wafer to be inspected to obtain wafer information, and generates a simulation map of the wafer MAP according to the obtained wafer information; scans the barcode of the wafer to be inspected through the PC, identifies the wafer to be inspected and obtains the prior information. The entered wafer information, where the wafer information includes wafer size, shot size, PCM size, and dicing line size, etc., and generates a wafer MAP simulation diagram corresponding to the wafer to be inspected based on the obtained wafer information. Such as figure 2 and image 3 In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com