DC high-voltage aluminum alloy cable for magnetic suspension system

A DC high voltage, aluminum alloy technology, used in insulated cables, power cables, cable/conductor manufacturing, etc., can solve problems such as the large proportion of cable prices and the inability of investors to bear, and achieve excellent electromagnetic shielding performance, reliable performance, The effect of reducing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

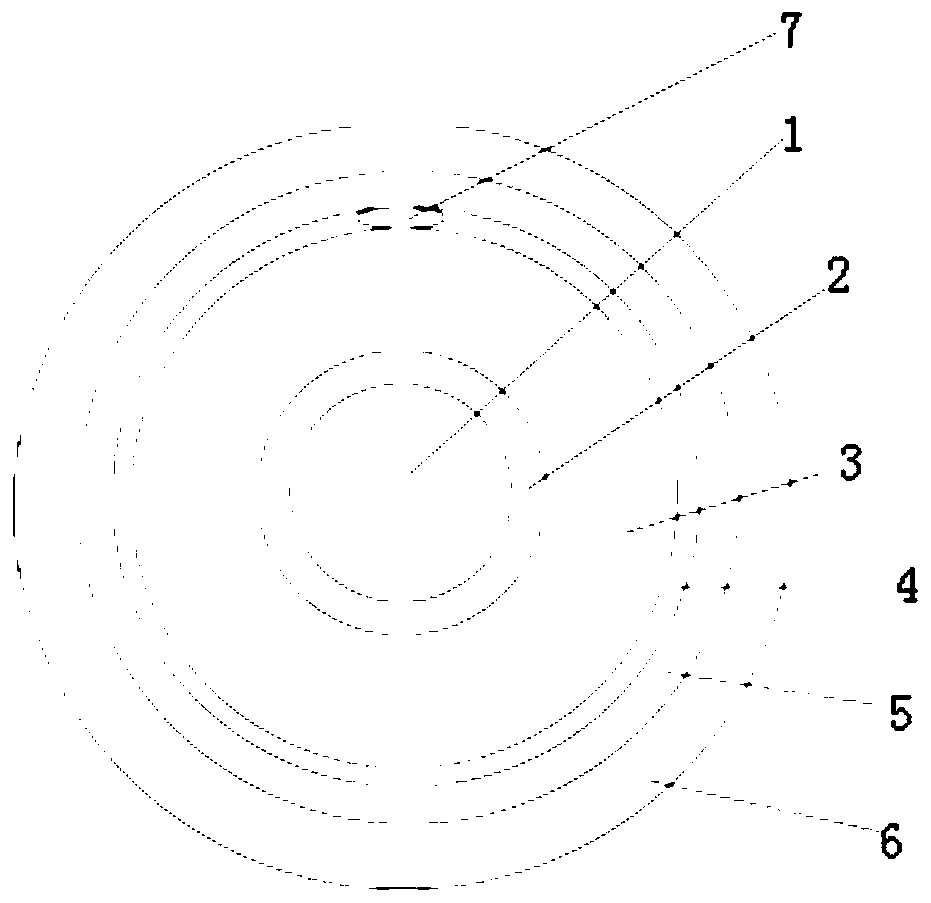

[0022] Such as figure 1 As shown, a DC high-voltage aluminum alloy cable for a magnetic levitation system includes an aluminum alloy conductor 1, and the outer side of the aluminum alloy conductor 1 is sequentially covered with a semiconductive shielding tape 2, a cross-linked polyethylene insulating layer 3, and a tinned copper wire Braided shielding layer 4, aluminum alloy belt interlocking metal sheath layer 5 and halogen-free low-smoke polyolefin outer sheath 6; the aluminum alloy conductor 1 is made of aluminum alloy wires tightly twisted and twisted. The alloy wire is drawn into a trapezoidal monofilament through a trapezoidal wire drawing die. The innermost aluminum alloy monofilament is round, and the outer layer of the round monofilament is wrapped with a trapezoidal monofilament. The mold is pressed tightly, and the filling rate of each layer is more than 95%; a guide wire 7 is also provided on the tinned copper wire braided shielding layer 4 .

[0023] The semi-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com