Railway wagon loading video intelligent monitoring system

A technology for railway wagons and monitoring systems, which is applied to instruments, biological neural network models, calculations, etc. It can solve problems such as high work intensity, hidden safety hazards, and low work efficiency, and achieves guaranteed image quality, strong environmental adaptability, and intelligent high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical solutions and advantages of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

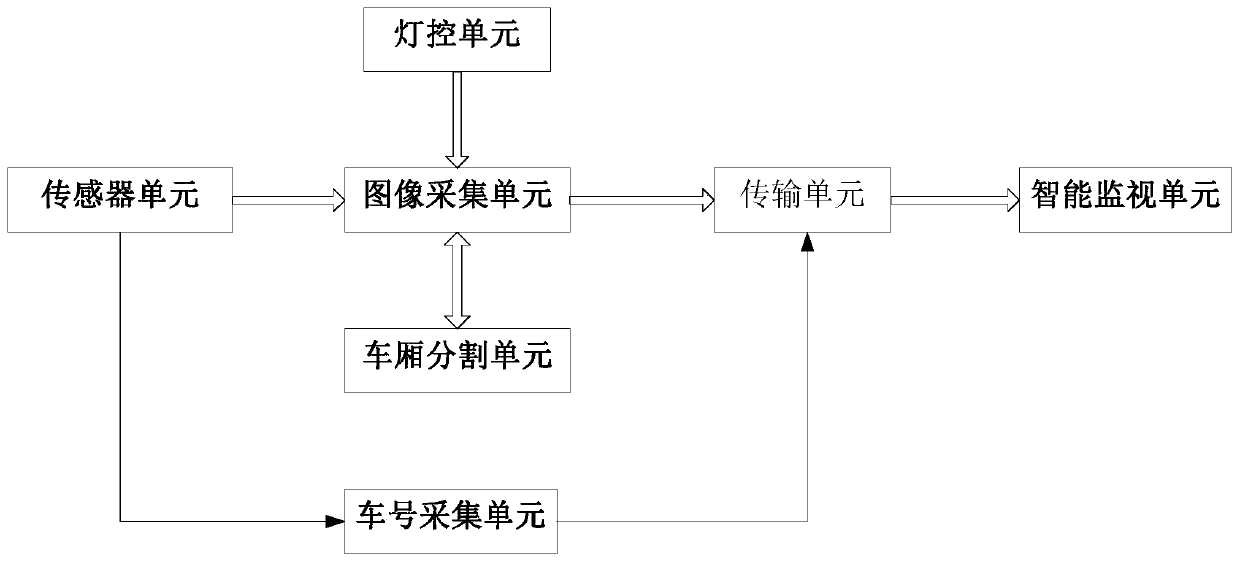

[0023] like figure 1 The shown intelligent video monitoring system for loading railway freight cars specifically includes: a sensor unit, an image acquisition unit, a car number acquisition unit, a light control unit, a compartment division unit, a transmission unit and an intelligent monitoring unit.

[0024] The sensor unit is installed next to the track at the entrance and exit of the station. When the train passes the detection point, the train will trigger the sensor units at different positions in turn. The sensor unit provides and transmits information such as start signal, train running direction, and train speed for the system. During the non-vehicle entry period, the system remains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com