LCD display panel, manufacturing method thereof, and terminal equipment

A technology for display panels and color filter substrates, which is used in printing image acquisition, instruments, computing, etc., can solve the problems of many lines, small effective use of LCD display panels, and inability to apply LCD display panels, etc., to achieve full-screen fingerprint recognition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

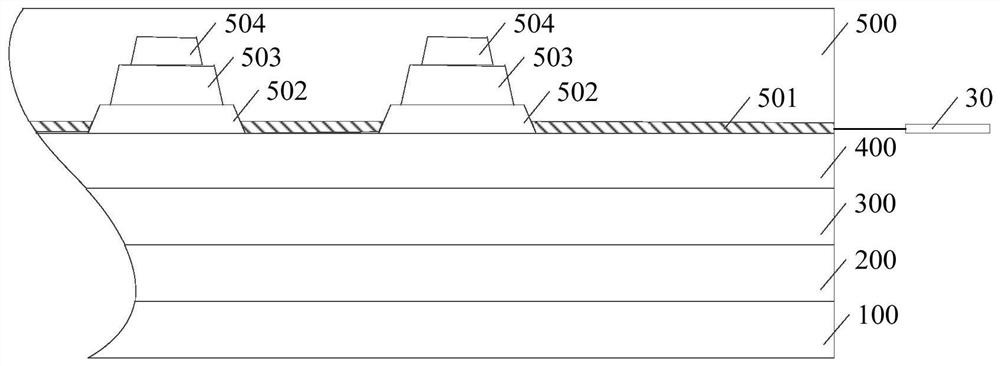

[0058] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0059] One embodiment of the present invention provides a method for preparing an LCD display panel, comprising:

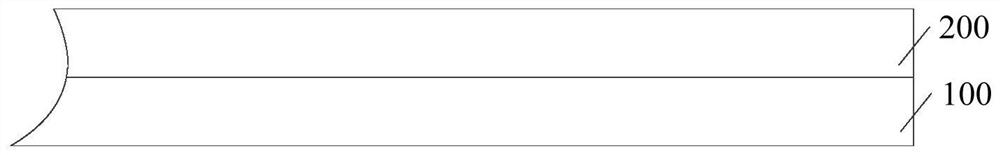

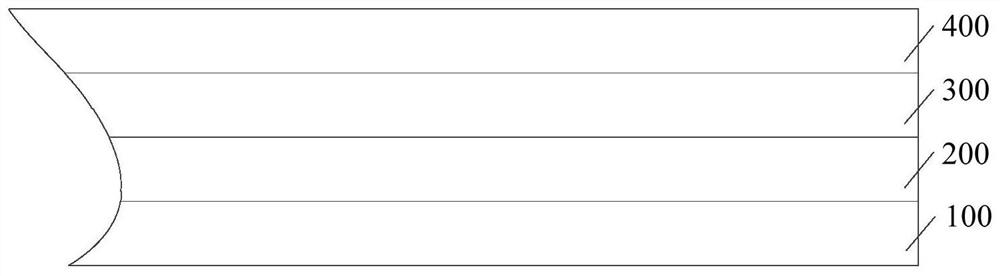

[0060] Step S1, such as figure 1 As shown, a capacitive touch layer 200 is formed on a TFT (Thin Film Transistor, thin film transistor) array substrate 100 .

[0061] Wherein, the method for forming the touch layer 200 can adopt the OGS process known in the art to separately form the capacitive touch layer 200 and bond it with the TFT array substrate 100 .

[0062] in addition, figure 1 What is represente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com