Small-caliber ammunition remote arming MEMS safety system and implementation method thereof

A safety system and small-caliber technology, applied in the field of small-caliber ammunition safety and security release control, can solve the problem of inability to meet the long-distance release insurance index of fuze, reduced reliability of small-caliber ammunition fuze action, and reduced quality and size of fuze security system, etc. problems, to achieve good consistency of processing samples, improve high integration, and achieve the effect of intelligent control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

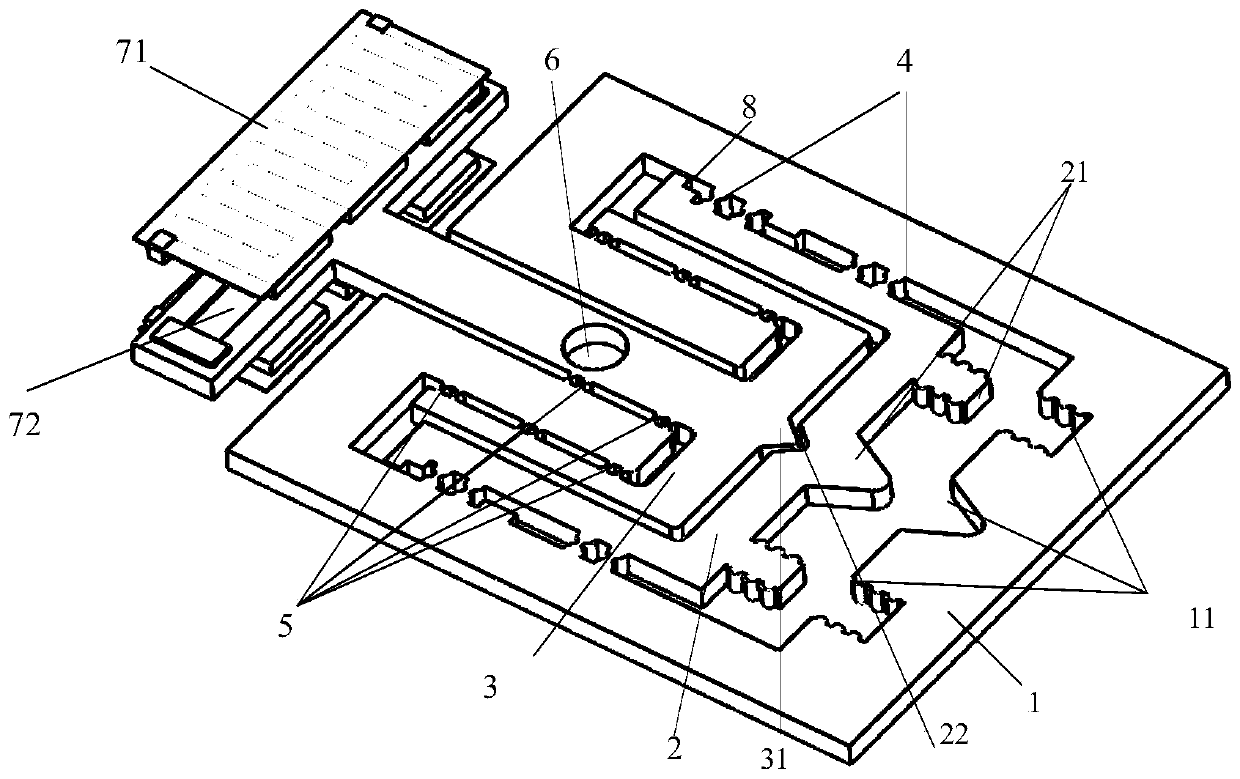

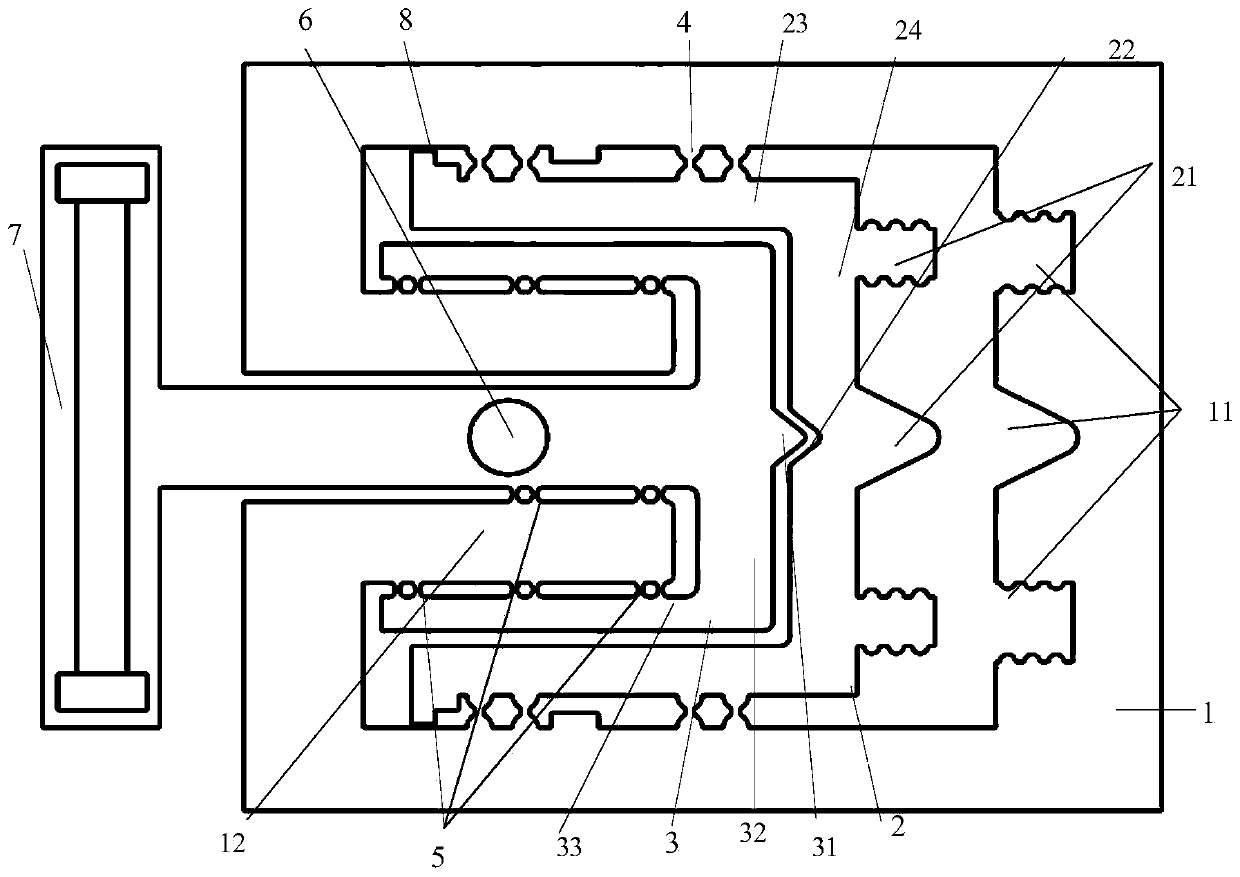

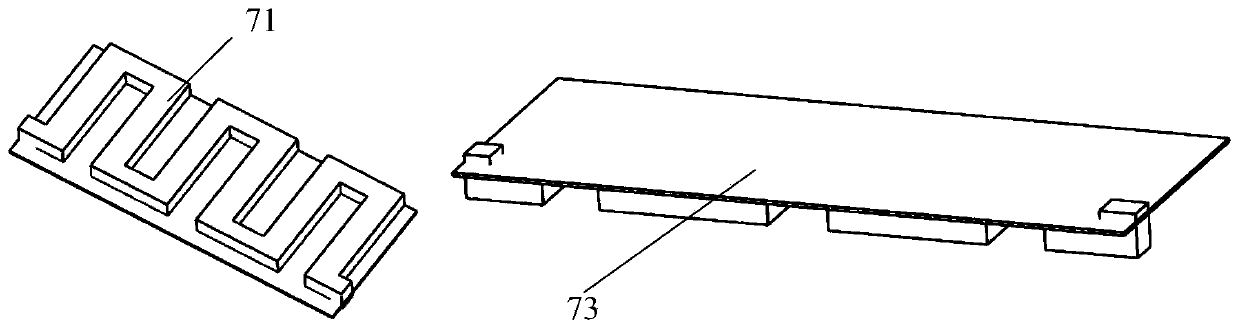

[0035] Such as figure 1 and 2 As shown, the MEMS safety system of the small-caliber projectile of the present embodiment for long-distance release includes: a limit frame 1, a recoil flameproof slider 2, a centrifugal flameproof slider 3, a frame limit groove 11, and a recoil limit pin 21 , recoil limit groove 22, centrifugal limit pin 31, recoil overload threshold judging mechanism 4, centrifugal overload threshold judging mechanism 5, explosion transmission hole 6, delayed unlocking device 7 and anti-shake device 8; MEMS safety system on centrifugal overload direction It is an axisymmetric structure; wherein, the limit frame 1 is an internal hollow frame structure, a recoil flameproof slider 2 is set in the limit frame 1, a centrifugal flameproof slider 3 is set in the recoil flameproof slider 2, and the limit The center planes of fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com