Asymmetric furnace arch structure capable of reducing boiler flue gas temperature difference

A technology of flue gas temperature deviation and flame angle, which is applied to steam boiler components, steam boilers, steam boiler accessories, etc., and can solve the problems of increased deviation, steam temperature deviation, superheater, reheater tube wall overheating, etc. problem, to achieve the effects of reduced smoke temperature deviation, consistent heat transfer, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

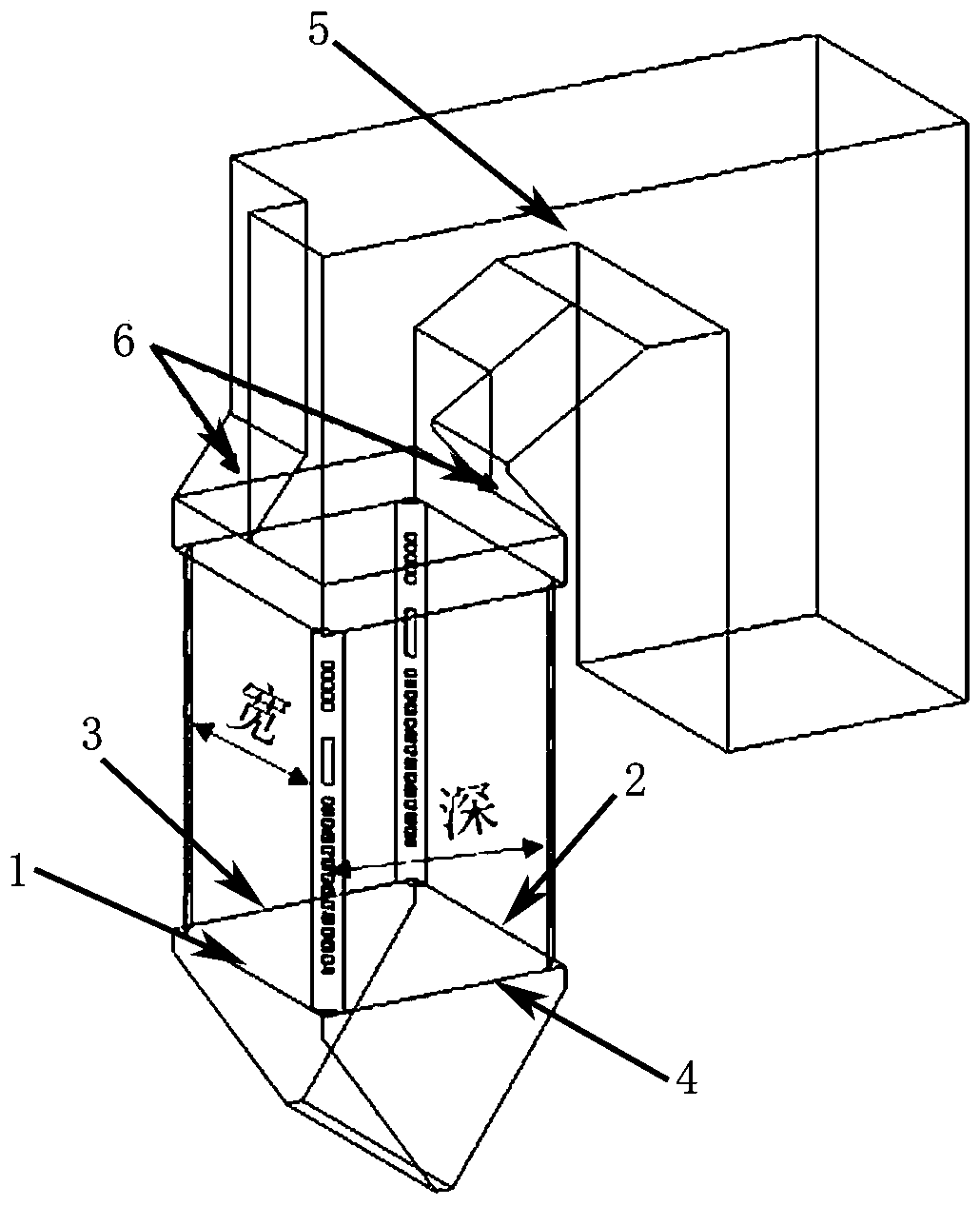

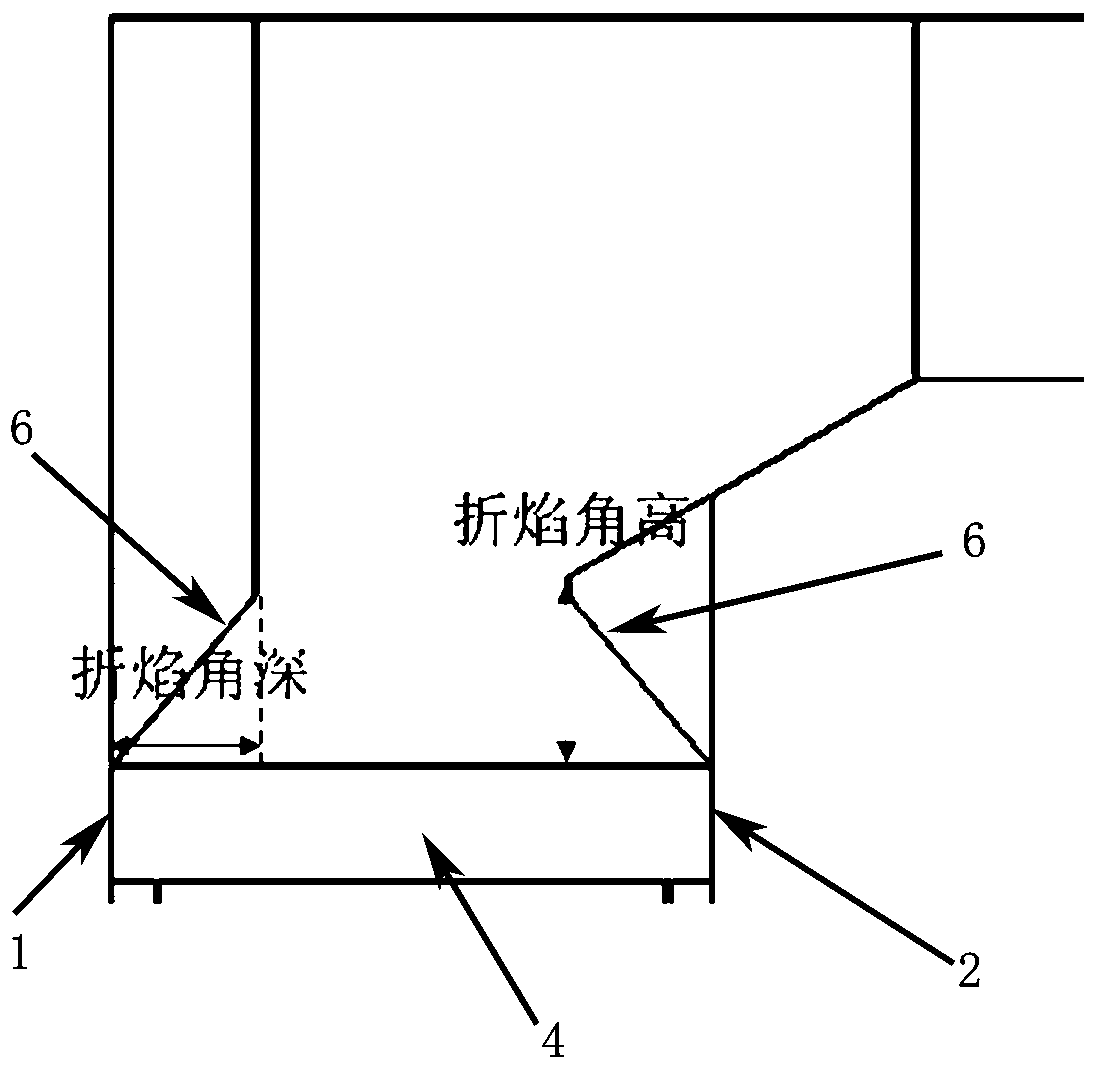

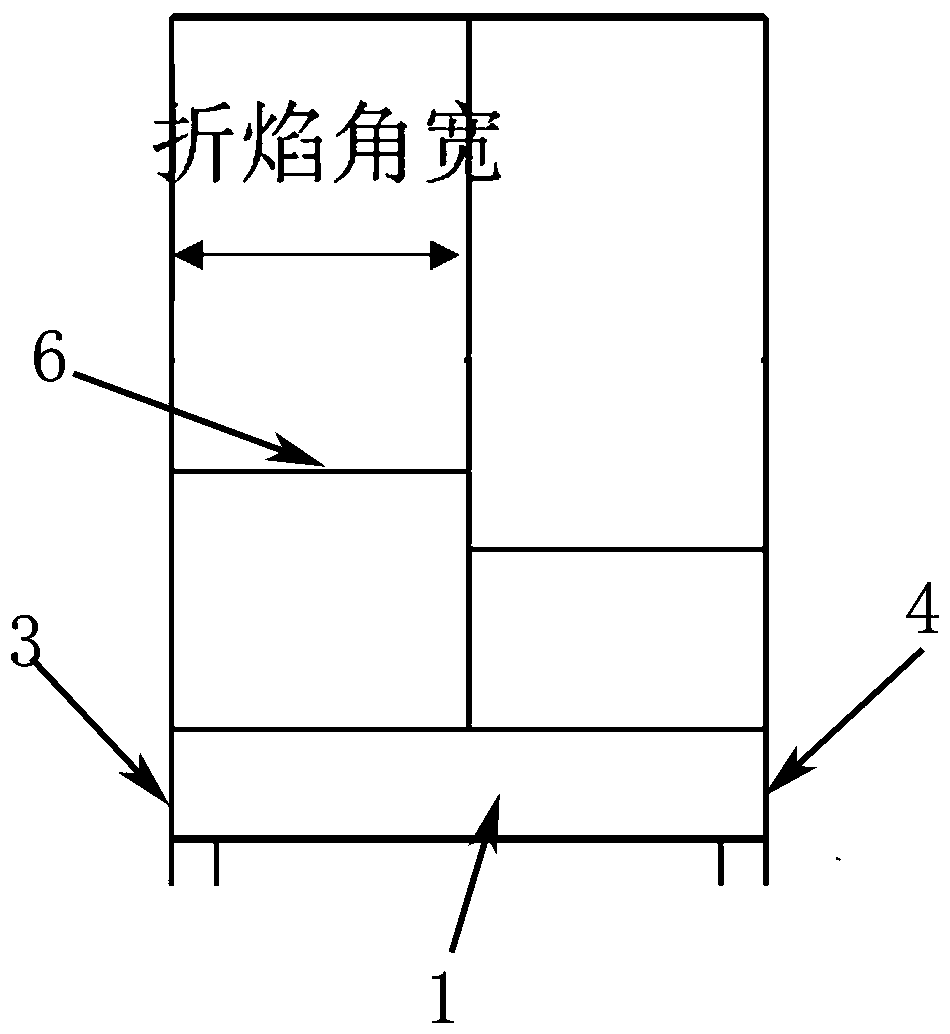

[0020] The present invention is an asymmetrical refraction angle 6 structure for reducing boiler flue temperature deviation, comprising a refraction angle 6 arranged at the junction of the horizontal flue 5 and the main combustion zone of the furnace, the main combustion zone of the furnace is defined by the front wall of the furnace 1. The back wall 2 of the furnace, the right wall 4 of the furnace and the left wall 3 of the furnace form a hollow columnar chamber; the said refraction angle 6 is set to two, and the two refraction angles 6 are respectively arranged on the front wall 1 of the furnace and the rear of the furnace On the wall 2; two refraction angles 6 are asymmetrically arranged on the front wall 1 and the rear wall 2 of the furnace.

[0021] The widths of the two refraction angles 6 are equal, and the width of the refraction angles 6 is half of the width of the furnace, which is the distance between the left wall 3 and the right wall 4 of the furnace.

[0022] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com