Methods and systems for electric turbocharger

A turbocharger, turbine technology, applied in electrical control, combustion engine, engine control, etc., can solve problems such as difficult installation, increase exhaust back pressure, and will not provide other functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

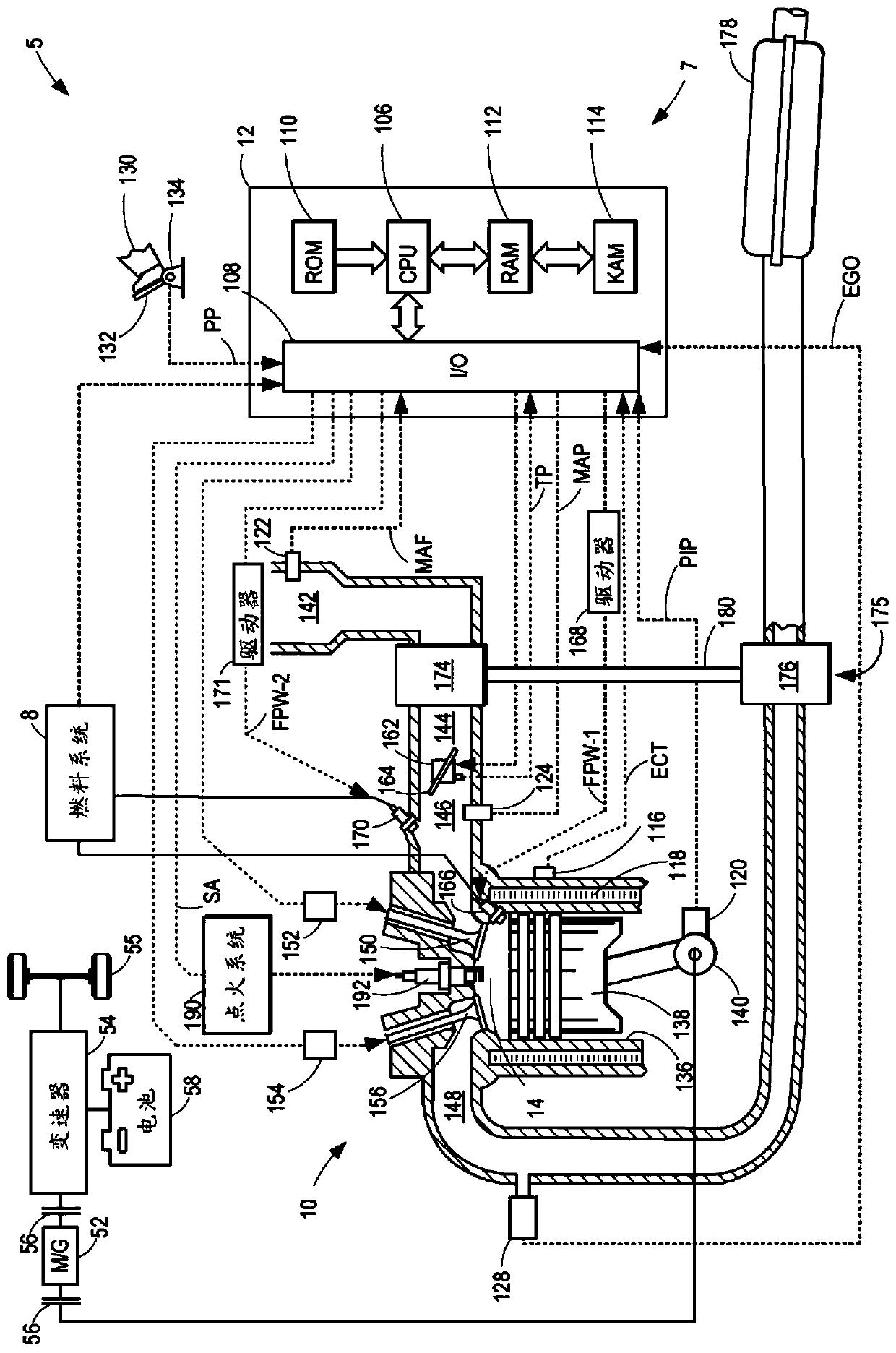

[0013] The following description relates to systems and methods for an electric turbocharger. Electric turbochargers may be included in hybrid vehicles that include engines such as figure 1 of hybrid vehicles.

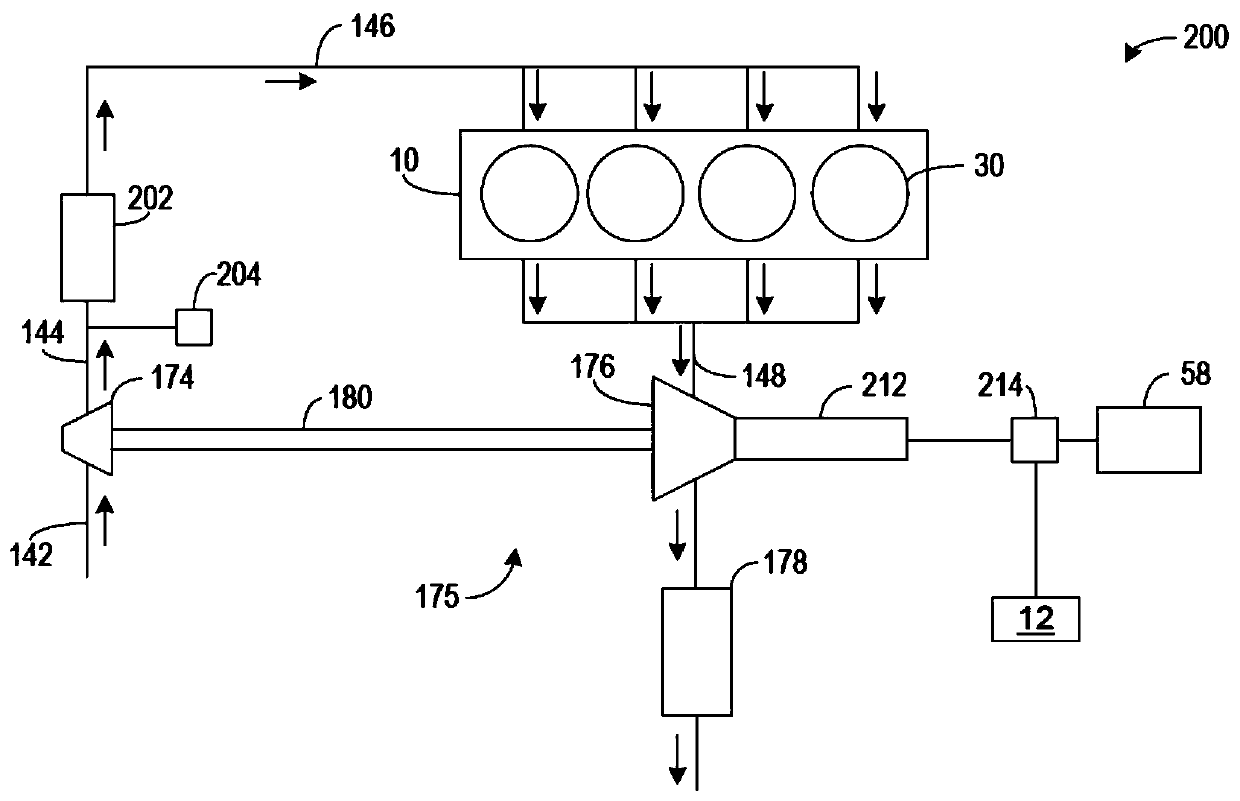

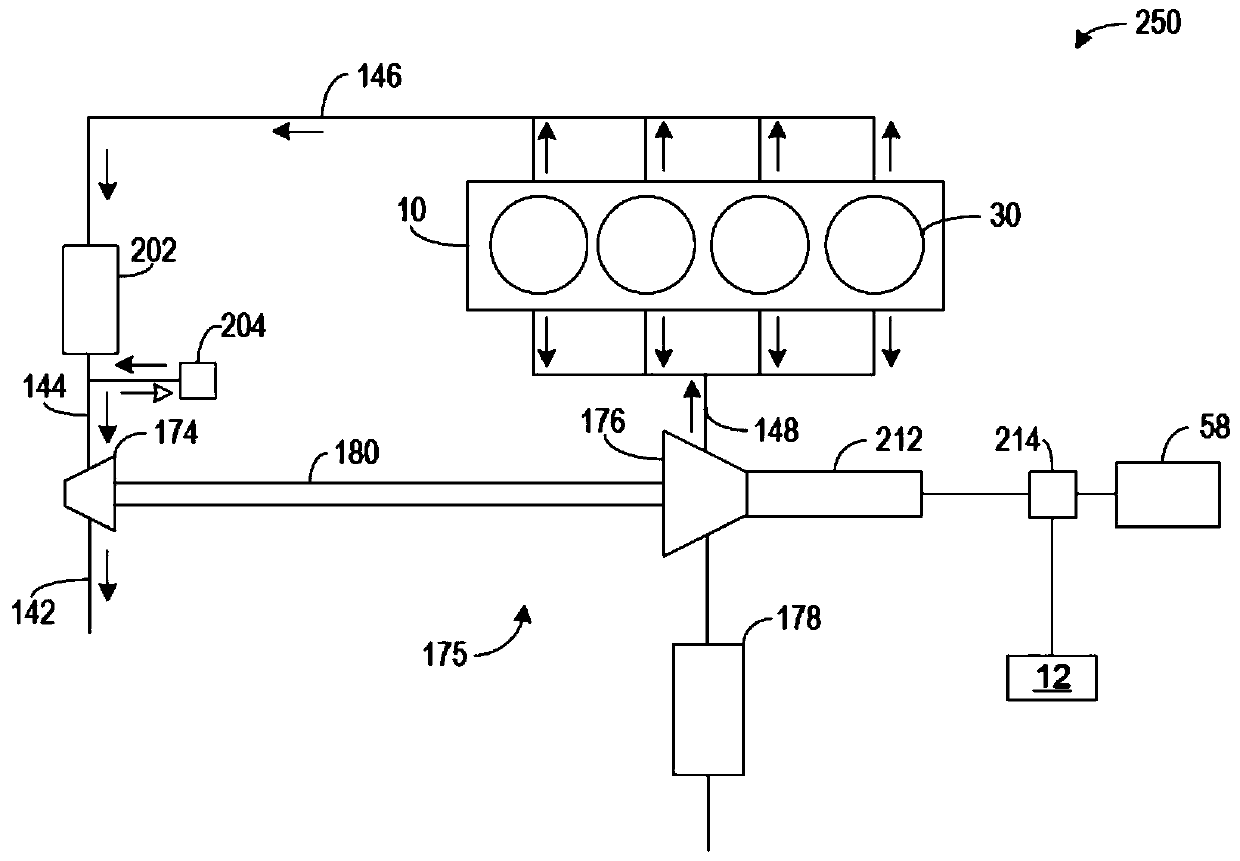

[0014] In some examples, an electric turbocharger includes an electric turbine mechanically coupled to a compressor. Turbine and compressor are shown along the Figure 2A Rotate in the forward direction. When the turbine and compressor rotate in the forward direction, charge air can flow to the engine. Therefore, exhaust backpressure may not increase, and manifold vacuum may not develop. However, when the turbine and compressor rotate in a reverse direction to the forward direction, exhaust backpressure may increase and manifold vacuum may develop, as in Figure 2B shown. Therefore, when the turbine and compressor rotate in opposite directions, charge air may not flow to the engine. The turbine and compressor can rotate in opposite directions during cold starts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com