Single-track railway tunnel full cross-section excavation rack and construction method thereof

A single-track railway, full-section technology, used in tunnels, tunnel linings, drilling equipment and methods, etc., can solve the problems of humanization, safety, low practicability, rough and simple processing, etc., and achieve convenient manual operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

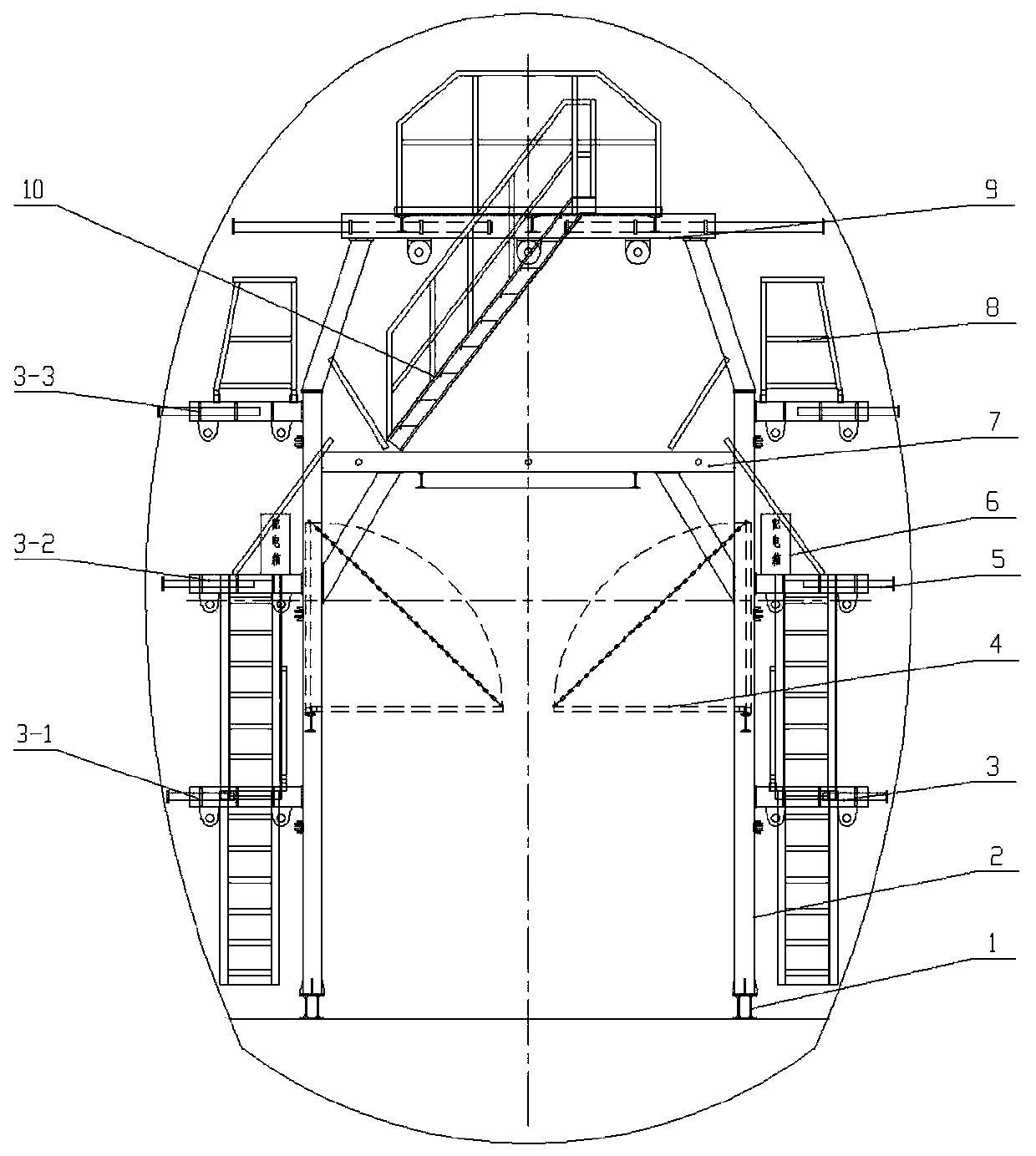

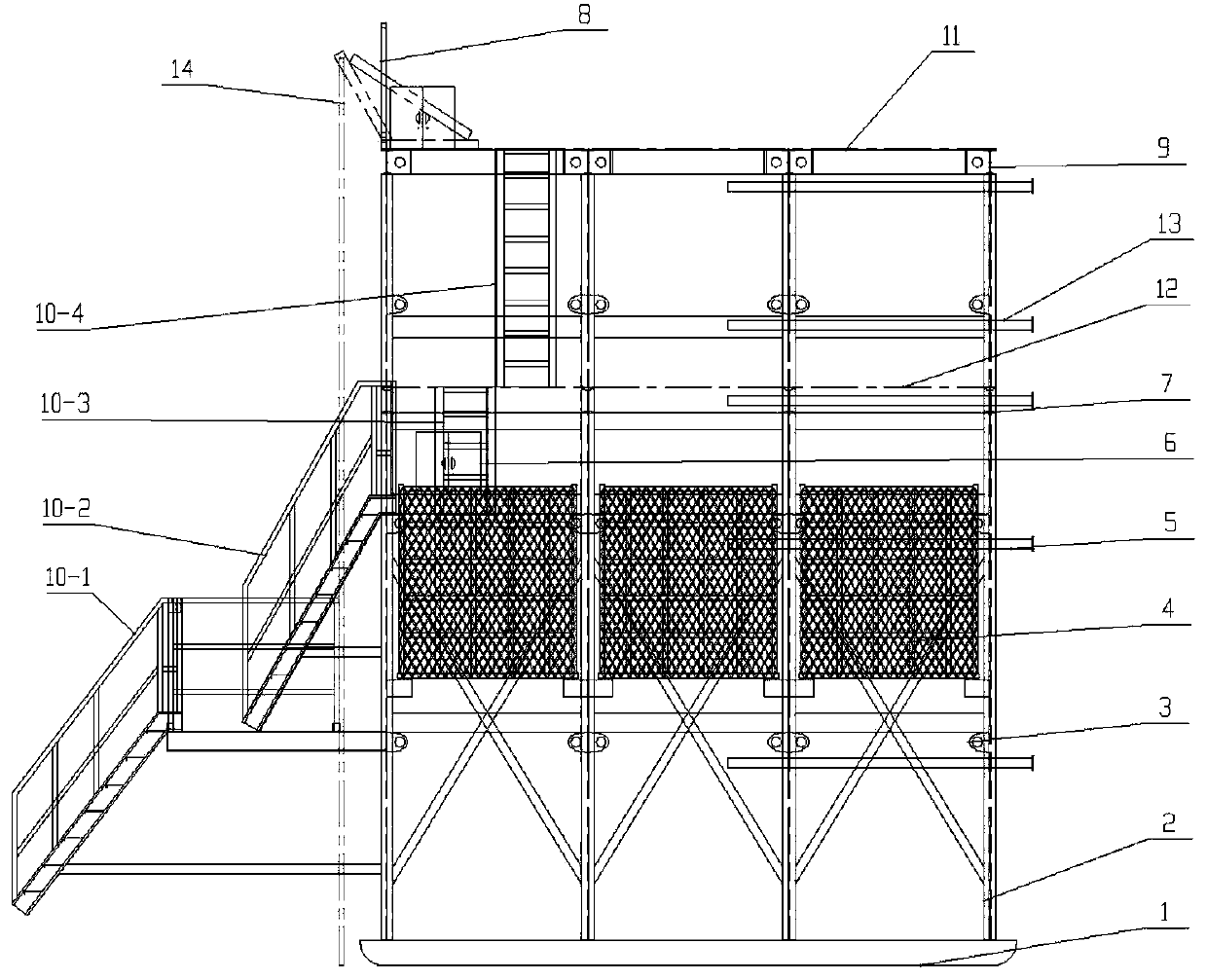

[0041] as attached figure 1 with 2 As shown, a full-section excavation bench of a single-track railway tunnel includes a bottom beam 1, a column 2, a side working platform 3, a middle turning working platform 4, a side telescopic sleeve 5, a distribution box 6, and a lower door beam 7. Guardrail 8, upper door beam 9, climbing ladder 10, upper working platform 11, middle working platform 12, front telescopic sleeve 13, escape rod 14. The above-mentioned components should be processed with steel materials, and the components should be connected in the form of bolts and flanges, and the necessary stiffness and stability calculations should be carried out.

[0042] There are two bottom beams 1, which are arranged parallel to each other. The bottom beams are designed as a ship-shaped structure to reduce the frictional resistance between the bottom beams and the ground when the platform is moved, and the two bottom beams 1 are equidistant along the length of the bottom beams. Ther...

Embodiment 2

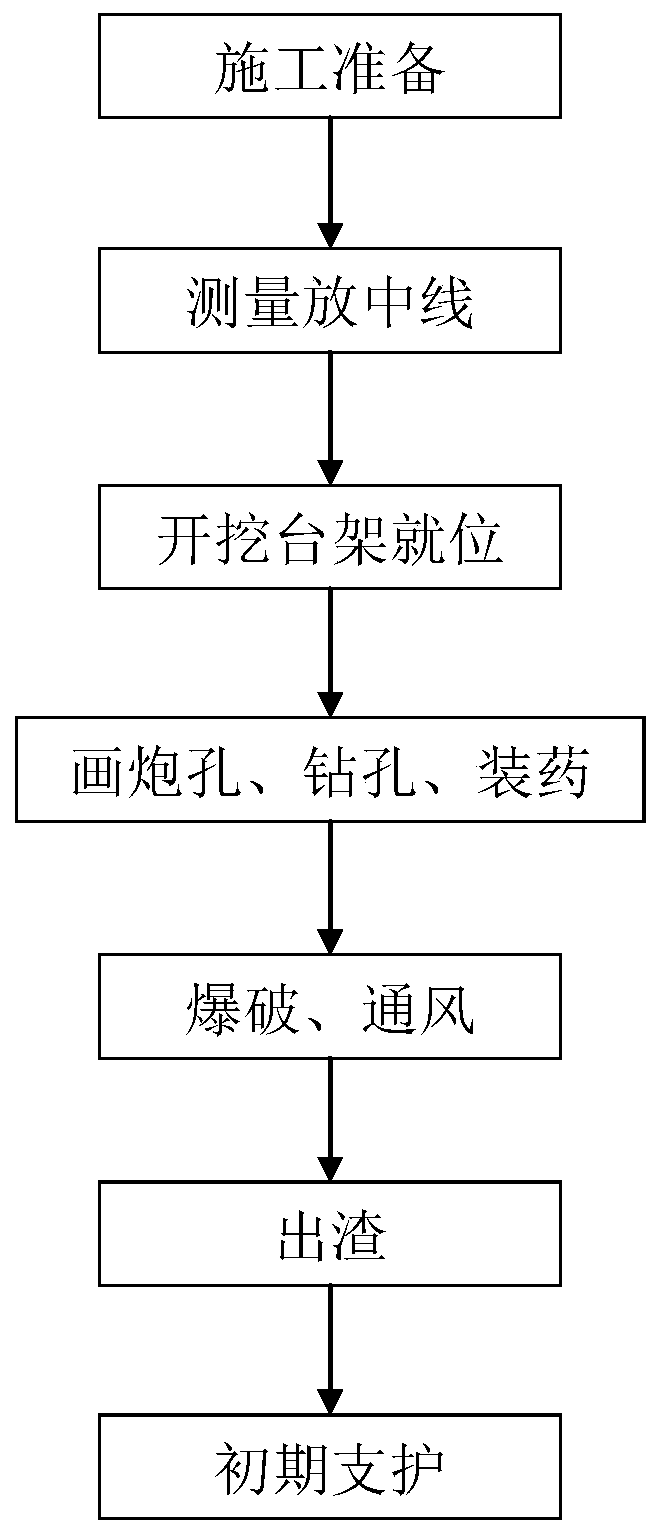

[0049] Such as image 3 Shown, specify construction method of the present invention:

[0050] Step 1. Construction preparation: carefully check the drilling equipment, wind, water, electricity and other pipelines before construction.

[0051] Step 2. Measure and set out the center line: before excavating the borehole, the surveyor should measure and set out the section, center line and elevation of the tunnel excavation.

[0052] Step 3, the excavation bench is in place: place the excavation bench at an appropriate position, extend all the side telescopic sleeves 5 and the front telescopic sleeve 13 to a suitable position on the rock surface of the tunnel and lay a metal expansion net, The middle part turning operation platform 4 is turned over, so that follow-up manual hole drawing, drilling and charge operation.

[0053] Step 4. Draw blastholes, drill holes, and charge: according to the measurement and setting out, draw the excavation positions of peripheral holes, bottom ...

Embodiment 3

[0058] Further, a power distribution box 6 is also arranged on the excavation platform, which is installed on any side working platform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Upper and lower spacing | aaaaa | aaaaa |

| Upper and lower spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com