Fracturing anti-roof tool

A technology of anti-roofing and tools, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of difficult operation of high-pressure wells, failure of oil wells to be put into production in time, etc., to achieve simple and firm anchoring, safe tripping, good blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

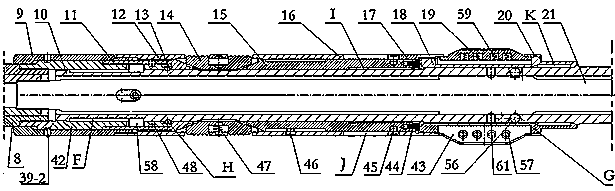

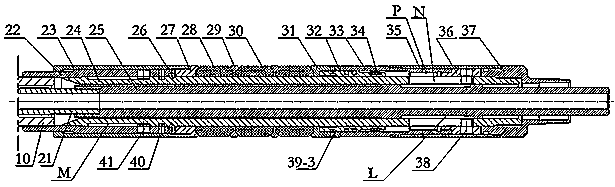

[0012] See figure 1 , The upper joint 1 is threadedly connected with the upper transmission shaft 2, and the upper transmission shaft 2 is processed with a liquid inlet A and a keyway B. The fixing sleeve 3 is connected with the release sleeve 5 through the release pin 39-1. The thrust spring 51 is placed outside the fixed sleeve 3 . The key 6 is connected to the release sleeve 5 through the socket head cap screw 50 and put into the keyway B of the upper transmission shaft 2 . The fishing joint 4 is threadedly connected with the transmission sleeve 7 and is provided with a set screw 60 with a hexagonal cone end, and the inner hole of the fishing joint 4 is provided with a fishing thread C. The transmission sleeve 7 is processed with a keyway D, and is threadedly connected with the transmission joint 8, and placed on the outside of the upper transmission shaft 2. See figure 2 , The middle transmission shaft 21 is threadedly connected with the lower end of the upper transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com