Push-back rotary steerable device based on drilling hydraulic pressure difference

A rotary steering, hydraulic differential technology, applied in directional drilling and other directions, can solve the problems of high manufacturing cost, high maintenance and maintenance cost, high maintenance and maintenance requirements of hydraulic system, and low service life of piston seals, and achieves simple structure and high-precision steering control. , the effect of fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

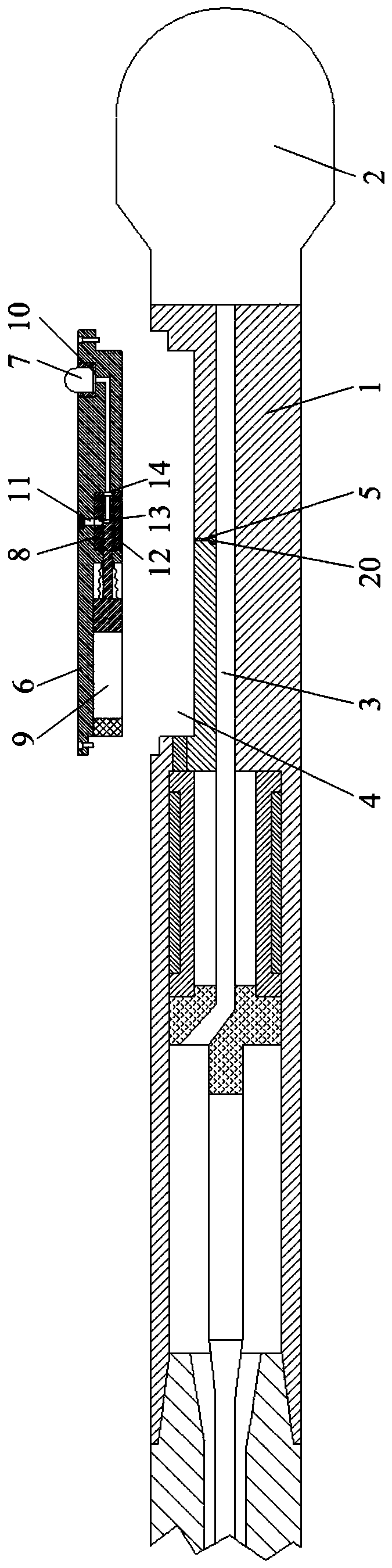

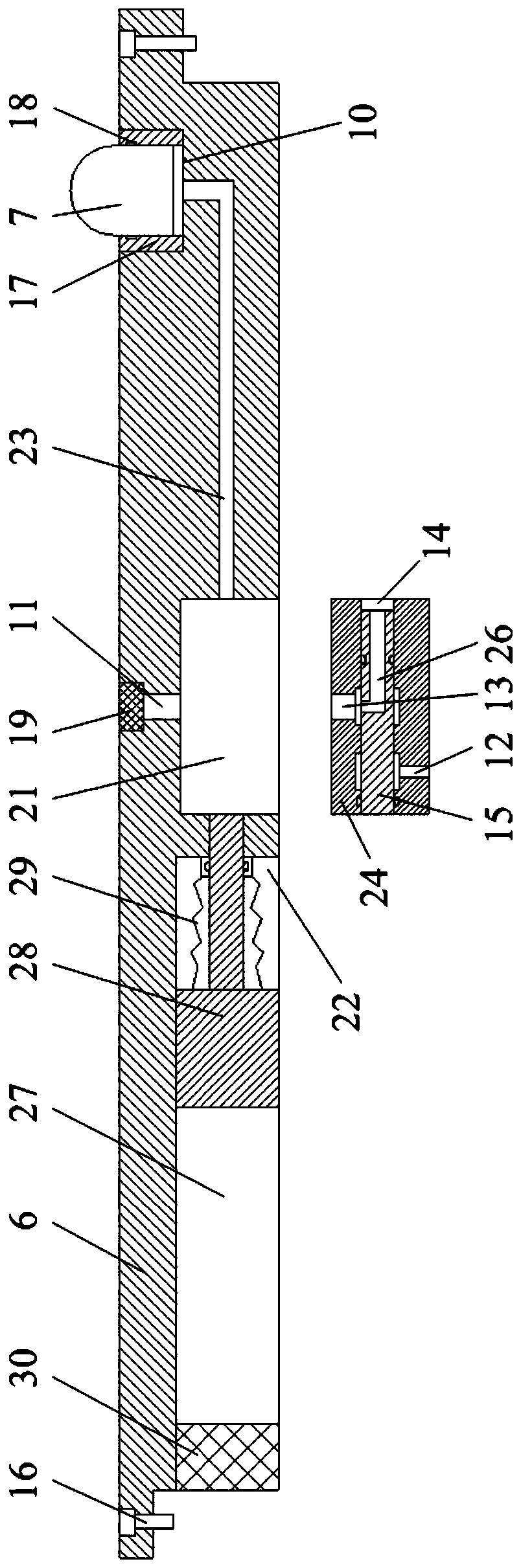

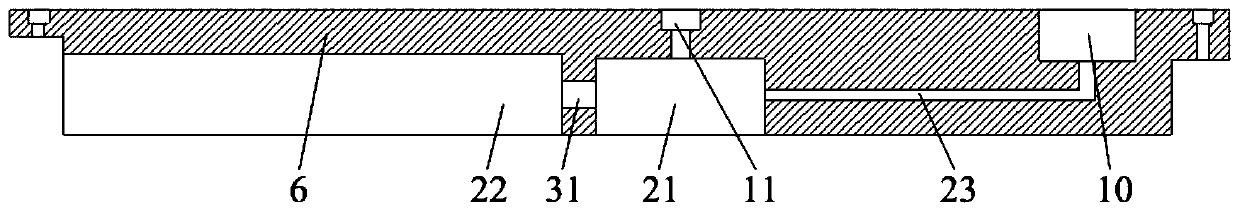

[0023] Embodiments of the invention: as figure 1 As shown, a push-to-type rotary steerable device based on drilling hydraulic pressure difference is applied to drilling tools, and specifically includes a drilling tool body 1 and a drill bit 2. It should be noted that the length of the drilling tool body 1 is very long. figure 1 Only one section containing the push-type rotary steerable device based on the drilling hydraulic pressure difference is shown in the figure. The drilling tool body 1 is provided with a mud flow channel 3 communicating with the drill bit 2. The outer wall of the drilling tool body 1 is provided with at least three The mounting grooves 4 are arranged at equal intervals, and each mounting groove 4 is provided with a set of pushing mechanism, and the drilling tool body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com