Manual hole digging operation safety protective cover

A technology of safety protection and manual digging, which is applied in the direction of construction, building structure, and construction material processing, etc., and can solve the problem of falling into the well, irregular wiring, and possibly accompanied by groundwater, quicksand, harmful gas, electric shock, objects, etc. To avoid problems such as blows, falling from heights, and wall collapse, etc., to achieve the effect of reducing the construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

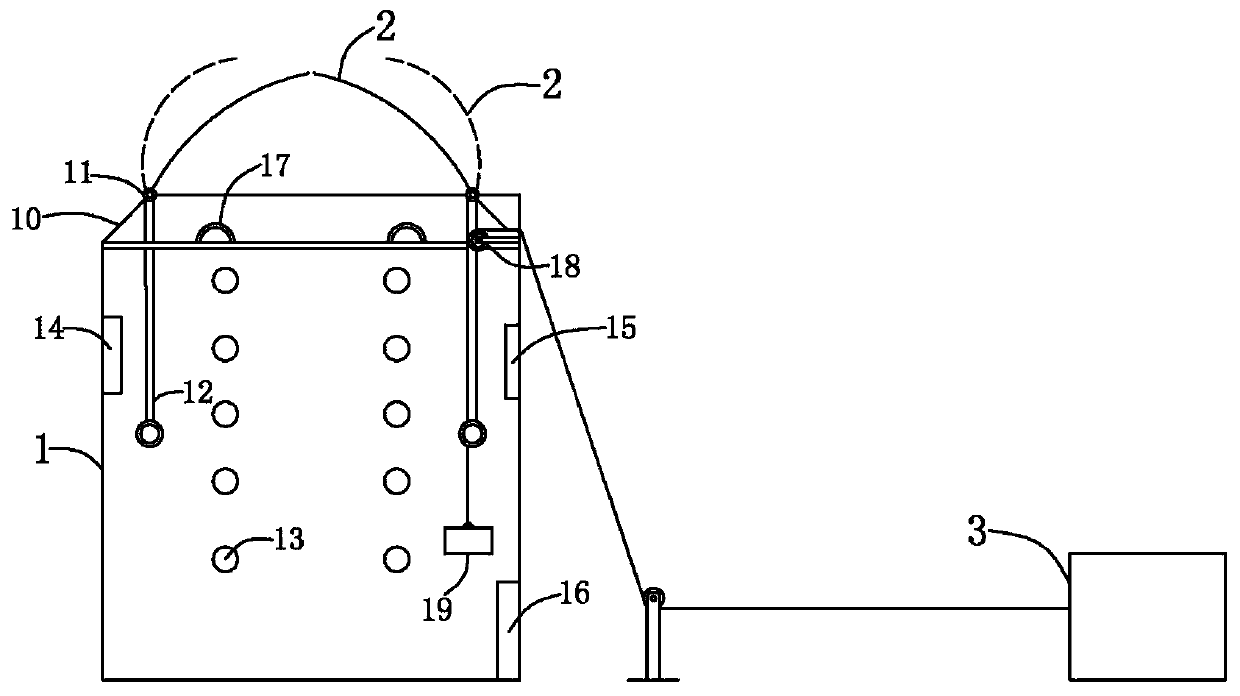

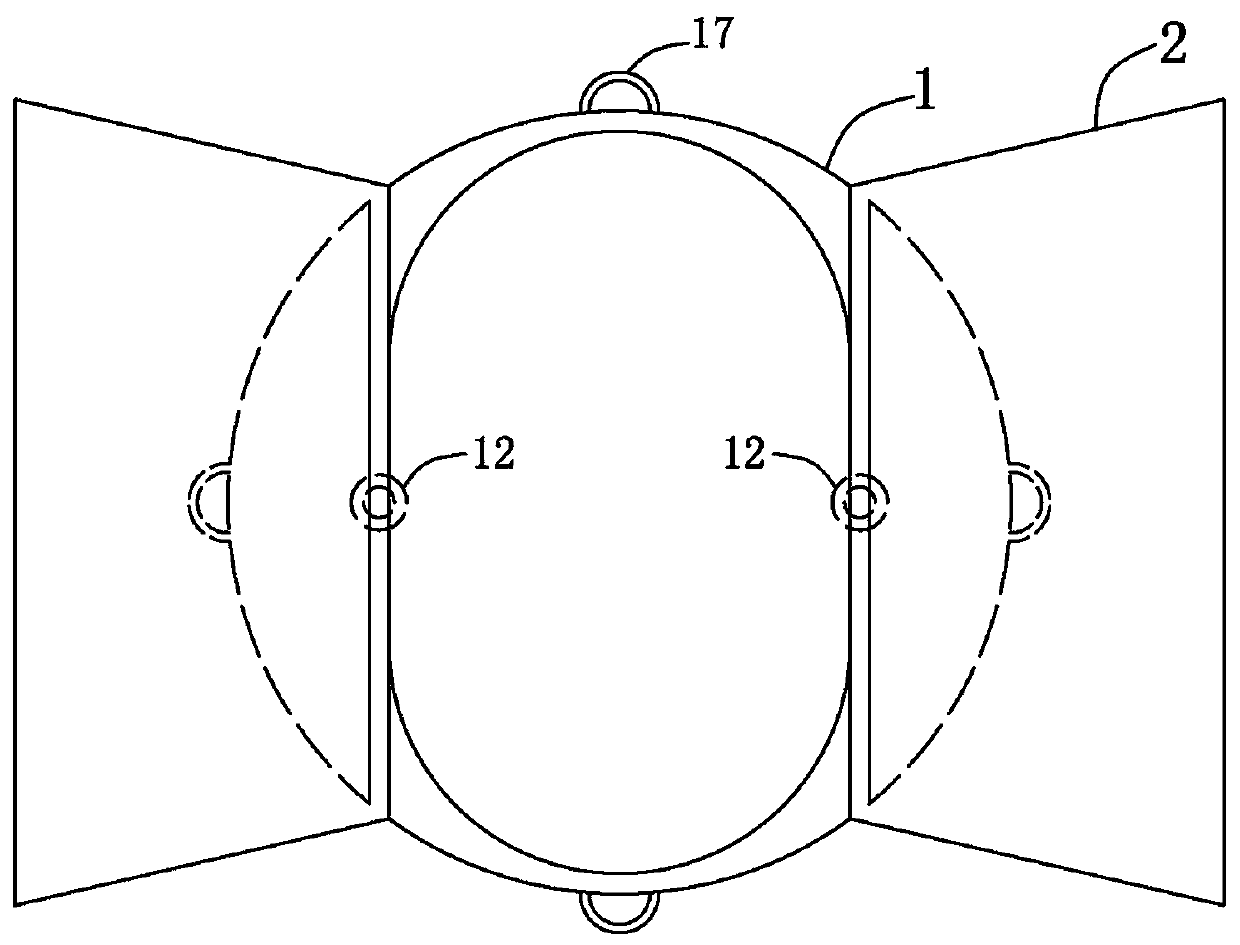

[0014] Embodiment, a kind of manual digging operation safety protective cover, as attached figure 1 And attached figure 2 As shown, including a lifting mechanism 3, the protective cover is composed of a cylindrical cover body 1 and a cover top 2, the upper end of the cover body 1 is provided with a support frame 11, and the cover top 2 passes through the rotating shaft arranged on the support frame 11. Hinged together with the cover body 1, the cover top 2 is composed of two curved panels with a large upper part and a smaller lower part, and a push rod 12 is arranged on the rotating shaft, and the push rod 12 hangs down into the cover body 1, so that if the protective cover The personnel in the construction below can control the opening and closing of the cover top at any time by pushing and pulling the push-pull rod; the cover body 1 is provided with a fixed pulley 18, and the fixed pulley 18 is connected with the lifting mechanism 3 arranged outside the protective cover for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com