Construction method of single pile vertical anti-pull static load test device

A technology of static load test and construction method, which is applied in the direction of foundation structure test, foundation structure engineering, construction, etc., and can solve the problems of many piled concrete blocks, high piled height, hidden safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

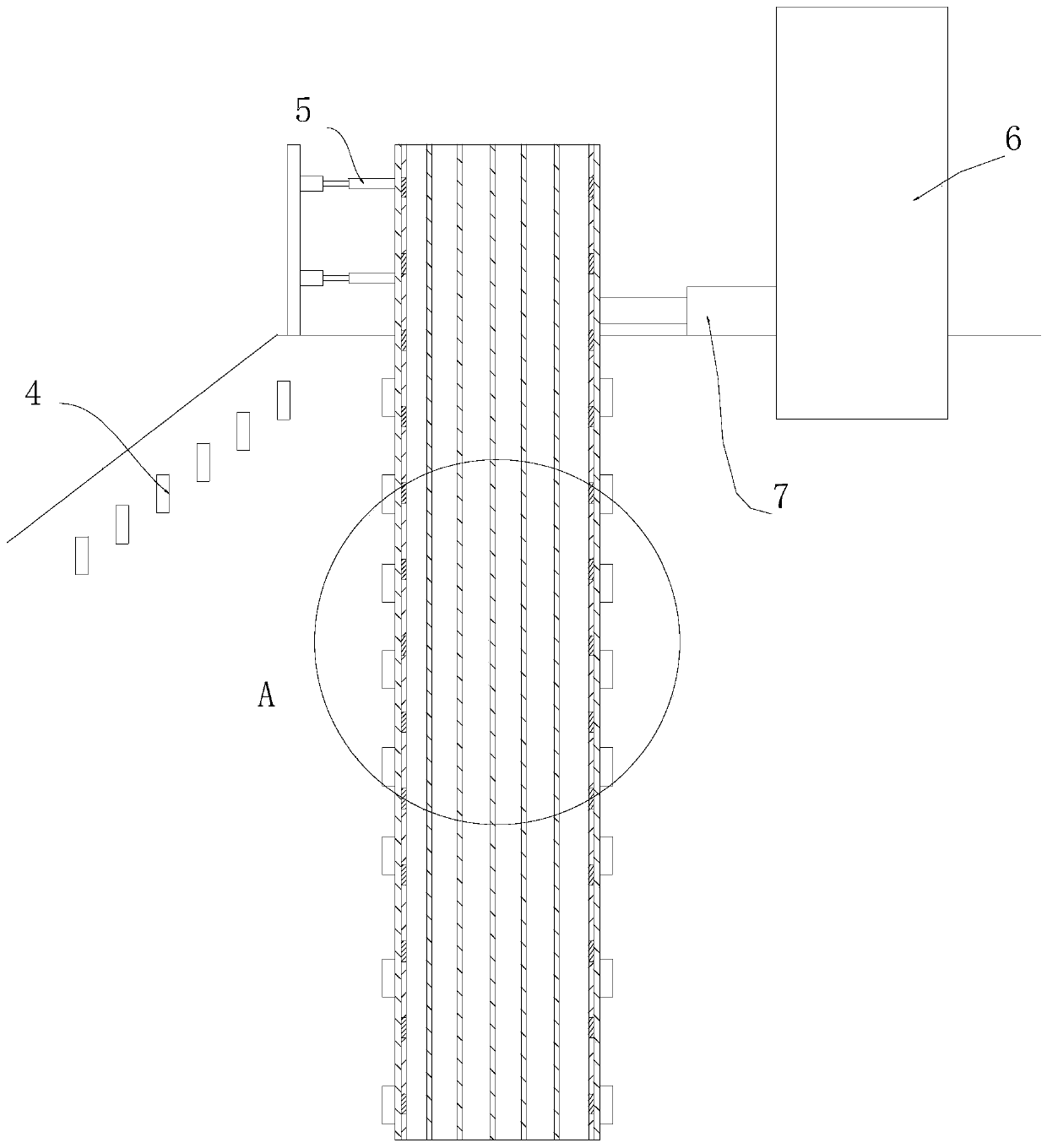

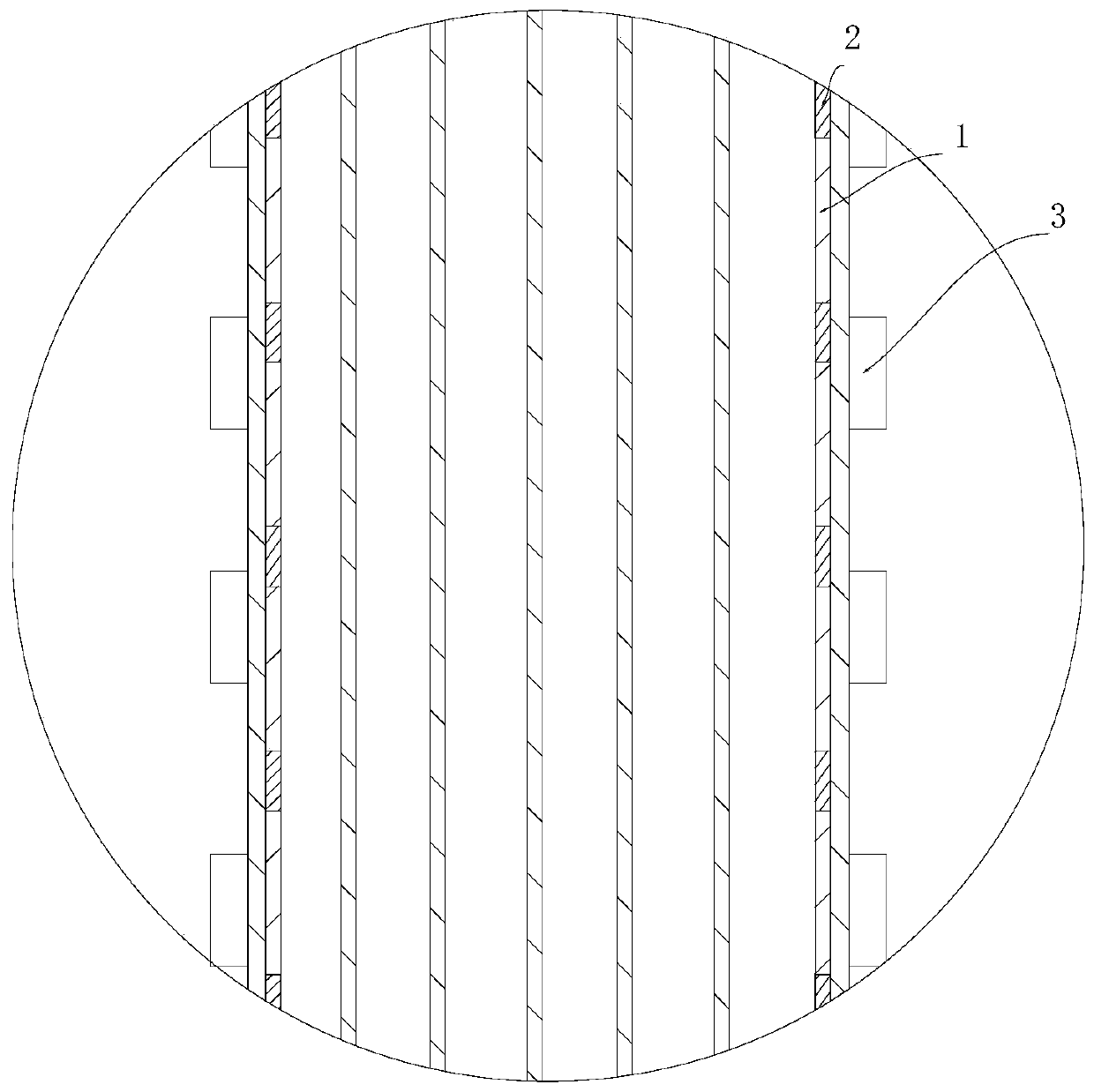

[0029] see Figure 1 to Figure 3 , when the output end of the jack 7 in the present invention applies pressure to the pile under inspection, the digital display displacement meter 6 arranged on the top of the pile under inspection performs data observation on the displacement of the pile top of the pile under pressure, and sets The inclinometer tube 1 on the steel cage of the pile under inspection conducts data observation on the displacement of the pile body under compression, and the reinforcement meter 2 installed on the reinforcement cage of the pile under inspection performs data observation on the pile body of the pile under inspection. Data observation is performed on the displacement that occurs under pressure, and the pile side soil pressure box 3 and the pile front side soil pressure box 4 arranged outside the pile body of the pile under inspection are used to observe the pressure data of the soil outside the pile body of the pile under inspection.

[0030] A constru...

Embodiment 2

[0041] The construction method of the single pile vertical pull-out static load test equipment of this embodiment is basically the same as that of Embodiment 1, the difference is that the termination loading conditions in step (S6) include breaking of the pile body, horizontal displacement of the pile body exceeding 100mm, load-displacement (H~Y0) curves show obvious bending tendency, the horizontal displacement of the pile body increases sharply under constant load, the displacement rate gradually accelerates, the reaction force structure is damaged or the horizontal loading device reaches the limit, and the test cannot be continued. In the present invention, when the test is carried out until the above-mentioned termination loading condition is met, the load is unloaded in stages to zero, thereby avoiding the deviation of test results and improving the accuracy of the test.

Embodiment 3

[0043] The construction method of the single pile vertical pull-out static load test equipment of the present embodiment is basically the same as that of embodiment 1, the difference is that in the step (S6), according to the estimated horizontal limit load of the single pile, it is divided into 10 grades, wherein the first grade The load is zero, so the level 1 and level 2 loads are combined into level 1, and the field test is carried out according to level 9. For each level of loading, the settlement of the bearing plate is read and recorded once every 5, 10, 15 and 30 minutes, and every half hour thereafter; when the settlement within one hour after each level of loading is less than 0.1mm, it is considered to have reached the relative Stable, the next level of load can be added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com