Near-infrared light regulated methacrylate monomer polymerization method

A technology of butyl methacrylate and methacrylic acid, which is applied in the field of methacrylate monomer polymerization regulated by near-infrared light, can solve the problems of "living" free radical polymerization system and few reports, and achieve a fast polymerization rate , high conversion rate and small molecular weight distribution index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the influence of different solvents on polymerization reaction

[0030] MMA (1.0 mL, 9.4 mmol) and CP-I (9.2 mg, 0.047 mmol) were added to a 5.0 mL ampoule preloaded with a stirring bar. Add organic solvent, freeze with liquid nitrogen, evacuate, and inflate three times to remove oxygen in the bottle, and then seal the tube with flame. The ampoule was then placed under near-red light at 25°C to stir the reaction. The light wavelength is 660nm, and the light intensity is 181.8mW / cm 2 , Take out after reacting for 24h, measure the molecular weight and molecular weight distribution of the polymethyl methacrylate (PMMA) that obtains with GPC.

[0031] In order to serve as a control, different experiments were carried out, different volumes of organic solvents were selected, reacted for the same time under the same light conditions, and the molecular weight and molecular weight distribution were measured by GPC. The results are shown in Table 1.

[0032] Th...

Embodiment 2

[0036] Example 2: 181.8mW / cm 2 Polymerization kinetics of MMA under light conditions

[0037] Use [MMA] 0 :[CP-I] 0 =200:1, the amount of MMA is 9.4mmol, 1.0mL DMI is used as a solvent, and the light wavelength is 660nm, at 181.8mW / cm 2 The polymerization reaction of MMA is carried out under the light of sunlight, and the reaction time is 3-21h. When table 2 is different polymerization time, the polymerization situation test result of gained PMMA.

[0038] Table 2 Polymerization kinetics data of MMA

[0039]

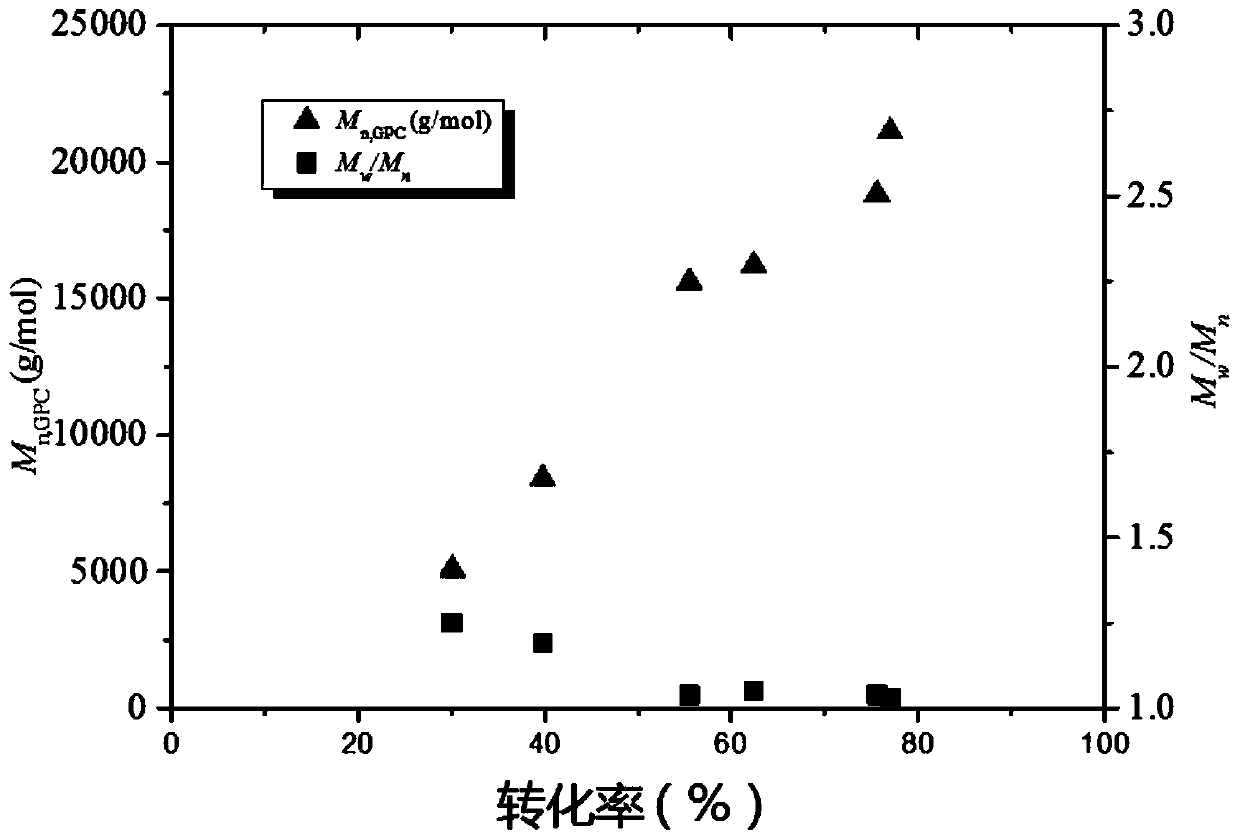

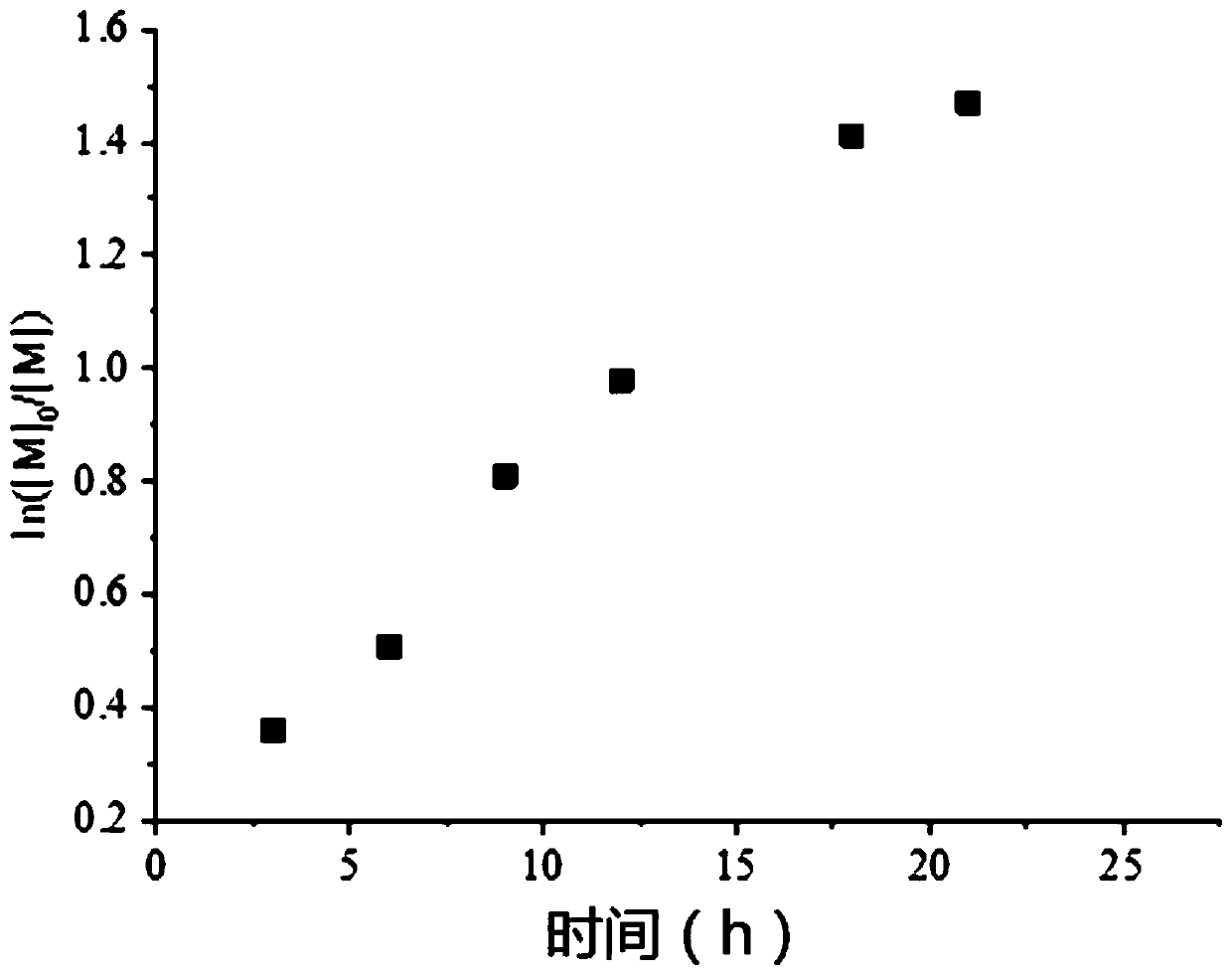

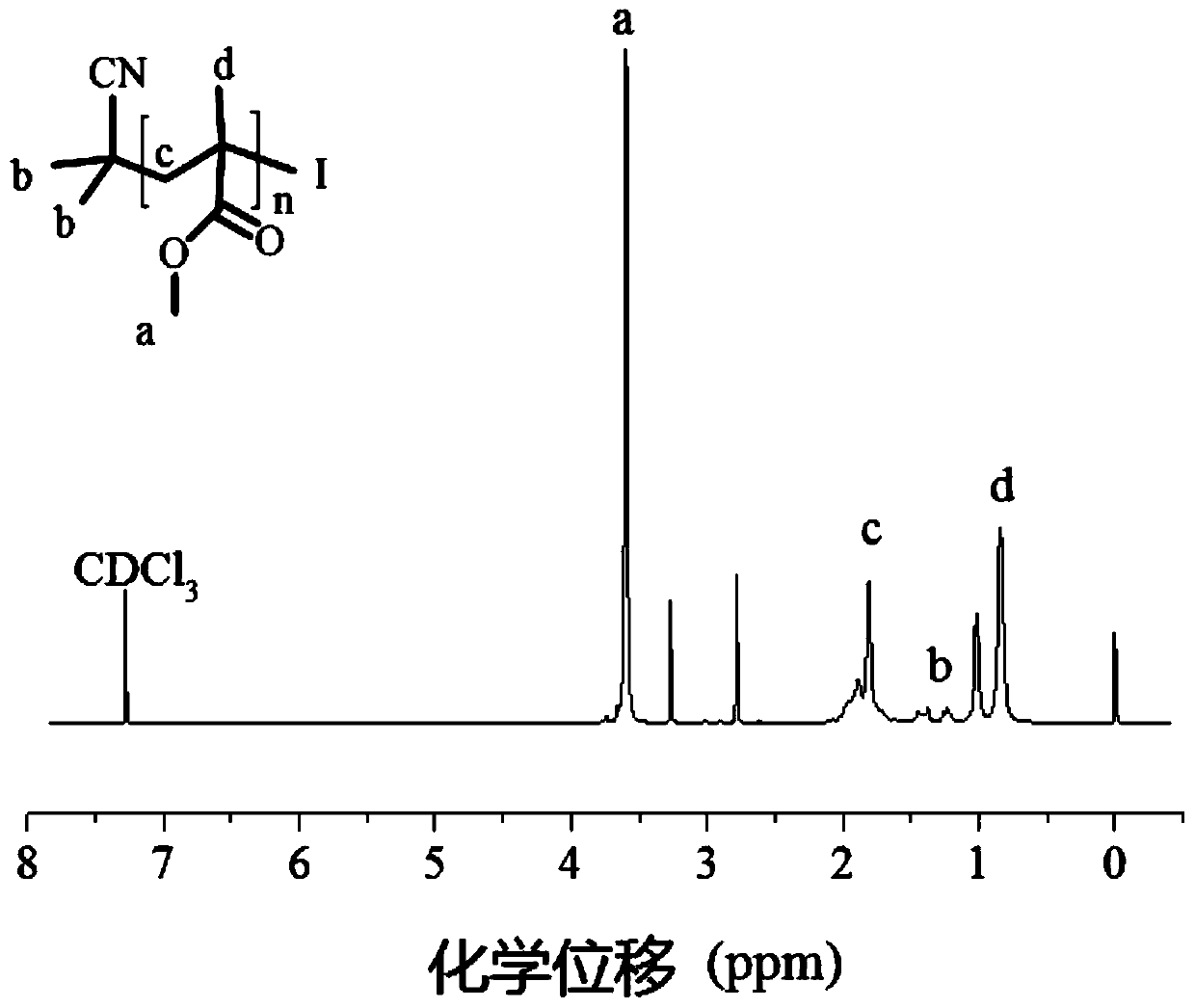

[0040] figure 1 is the number average molecular weight (M) of the catalyst-free solution LRP reaction of MMA n,GPC ) and molecular weight distribution (M w / M n ) and monomer conversion. figure 2 is the ln([M] of the above reaction 0 / [M]) versus time.

[0041] The above results show that under the condition of 660nm red light, when the reaction reaches more than 15h, the conversion rate of the monomer reaches about 75%. The molecular weight distribution ...

Embodiment 3

[0043] Example 3: 98.4mW / cm 2 Polymerization kinetics of MMA under light conditions

[0044] Use [MMA] 0 :[CP-I] 0 =200:1, the amount of MMA is 9.4mmol, 1.0mL DMI is used as a solvent, and the light wavelength is 660nm, at 98.4mW / cm 2 The polymerization reaction of MMA is carried out under the light of sunlight, and the reaction time is 5-25h. When table 3 is different polymerization time, the polymerization situation test result of gained PMMA.

[0045] Table 3 Polymerization kinetics data of MMA

[0046]

[0047] Figure 4 is the number average molecular weight (M) of the catalyst-free solution LRP reaction of MMA n,GPC ) and molecular weight distribution (M w / M n ) and monomer conversion. Figure 5 is the ln([M] of the above reaction 0 / [M]) versus time.

[0048] The above results show that at 98.4mW / cm 2 Under light, the conversion rate and molecular weight of MMA increase linearly with time, ln([M] 0 / [M]) shows a good linear relationship with time, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com