A shredded tobacco receiving production line integrating unstacking, unpacking and unloading

A production line and shredded tobacco technology, which is applied in the field of shredded tobacco receiving production line, can solve problems such as difficult to cut effectively, low operating efficiency, and affect production efficiency, etc., to reduce labor intensity, lower installation and maintenance costs, and improve unpacking efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

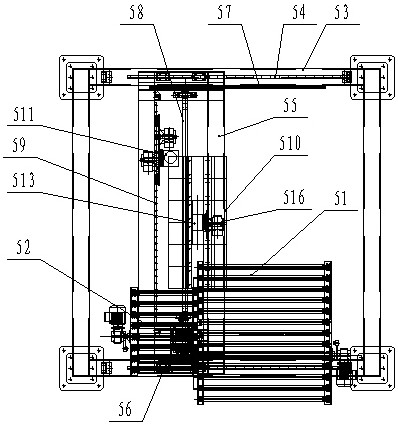

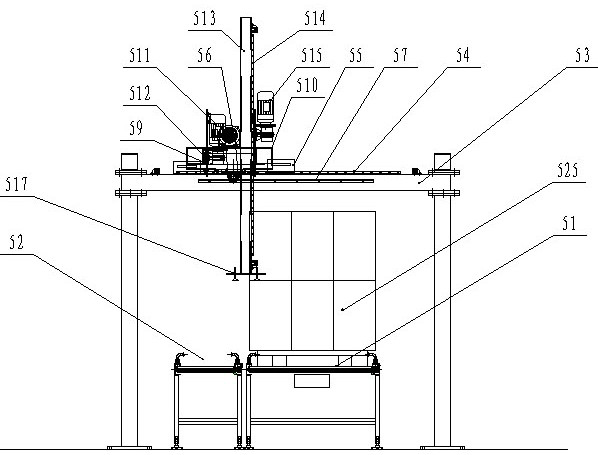

[0058] Such as Figure 1 to Figure 9 As shown, a shredded tobacco receiving production line integrating unstacking, unpacking and unloading of the present invention is mainly composed of unstacking unit, unpacking unit, top box unit and unloading unit.

[0059] The depalletizing unit is used to disassemble the stack of cases into individual cigarette cases, such as Figure 2 to Figure 3 As shown, the unstacking unit includes an unstacking station 51 and a single box placement station 52 located on the left side of the unstacking station 51 . The unstacking station 51 is a case stacking roller conveyor, and the corresponding position of the case stacking roller conveyor and the unstacking station is provided with a positioning device. The positioning device can use a photoelectric sensor. The case stack 525 is placed on the pal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com