An automobile bracket with an insert and a die-casting mold for forming the bracket

A technology of die-casting molds and inserts, which is applied to vehicle parts, control devices, transportation and packaging, etc., which can solve the problems of low porosity, high production capacity requirements, and difficult mold release of brackets, so as to achieve low porosity and good product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments, but the present invention is not limited to these embodiments.

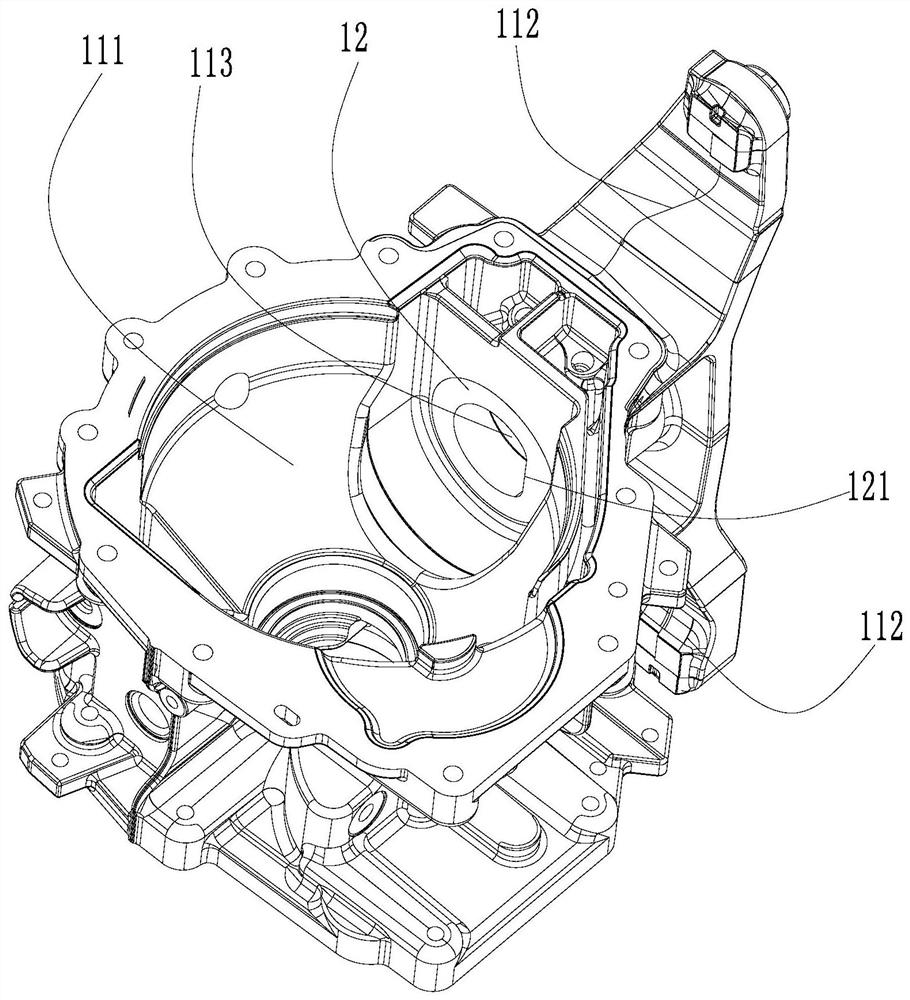

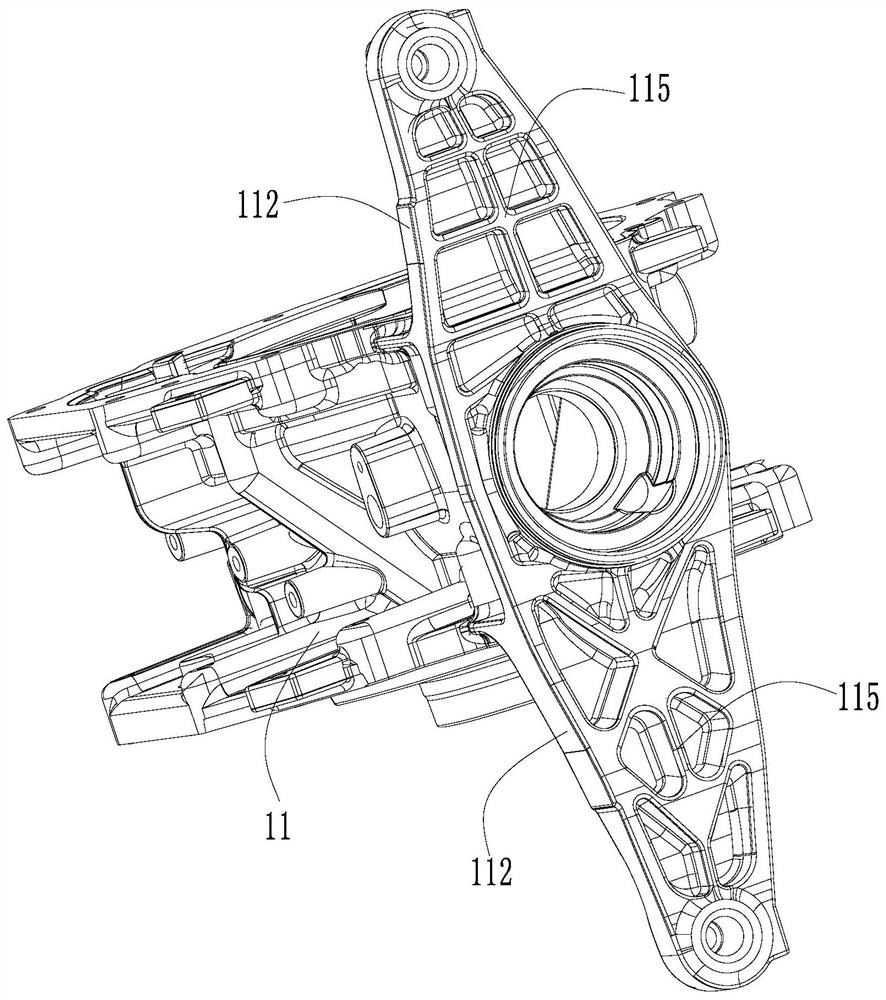

[0037] Such as Figure 1-11 As shown, an automobile bracket with an insert includes: a body 11 and an insert 12 .

[0038] The main body 11 is provided with an installation cavity 111 on the upper part of the main body 11, and the side of the main body 11 protrudes to form two brackets 112; Communication; the insert 12 is set in the through hole 113 and is on the side close to the installation cavity 111 ; the insert 12 is provided with a positioning surface 121 . The insert 12 is ring-shaped, and the positioning surface 121 is on the inner ring surface, which is used for the positioning of the insert 12 fixed in the mold; and the inner ring surface of the insert 12 is provided with 0 A slope of ~3 degrees means that the inner diameter of the inner ring sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com