Forming technique using springs to adjust mobile cavity

A technology of movable cavity and molding process, applied in the direction of coating, etc., can solve the problems of uneven thickness, large flow resistance, and difficult to form, and achieve the effect of not easy to separate from each other, uniform thickness, and easy to form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The molding process of adjusting the movable cavity through the spring in the present invention is suitable for producing thin-walled products, battery back covers, mobile phone cases or optical products, and the materials used are high-viscosity materials or low-viscosity materials, composite materials that are not Composite materials separated from each other.

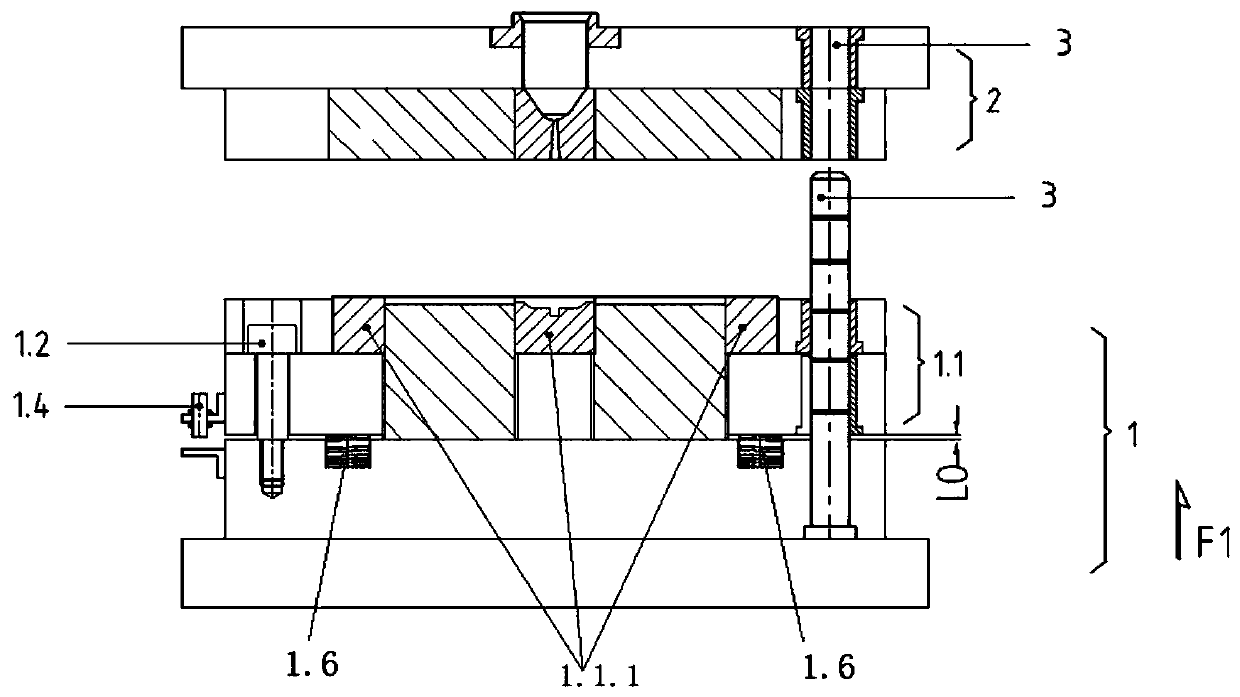

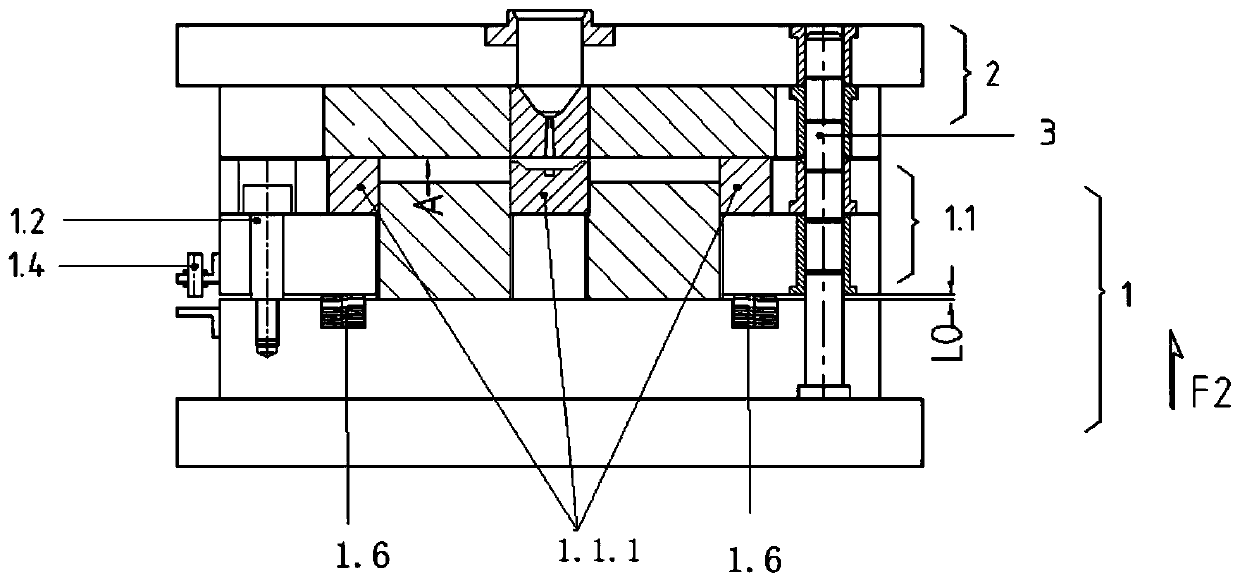

[0041] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14 , to describe in detail the preferred embodiments 1 and 2 of the molding process of adjusting the movable cavity through the spring of the present invention.

[0042] In the first preferred embodiment of the present invention, it is a molding process of a thin-walled product such as a light guide plate.

[0043] The thickness of the light guide plate is 0.4mm, the length is 152mm, and the width is 70mm. The raw mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com