Building component molding robot module and building component molding method

A technology for building components and robots, which is applied to the on-site preparation of building components, building construction, and construction, etc., can solve the problems of building cementitious materials condensation, high labor costs, and high work intensity, so as to improve the construction progress, improve the Investment benefit and social benefit, the effect of reducing worker dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

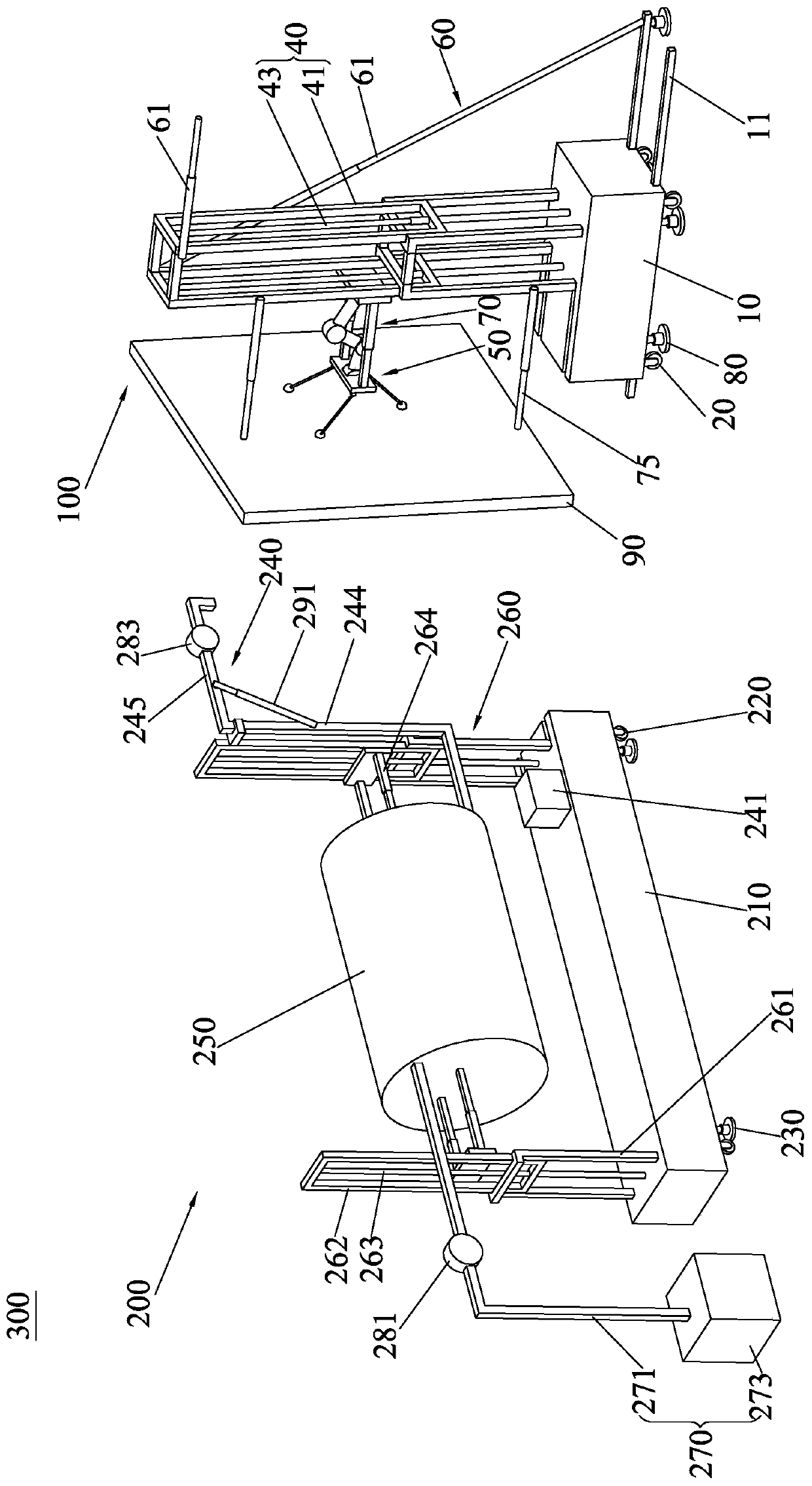

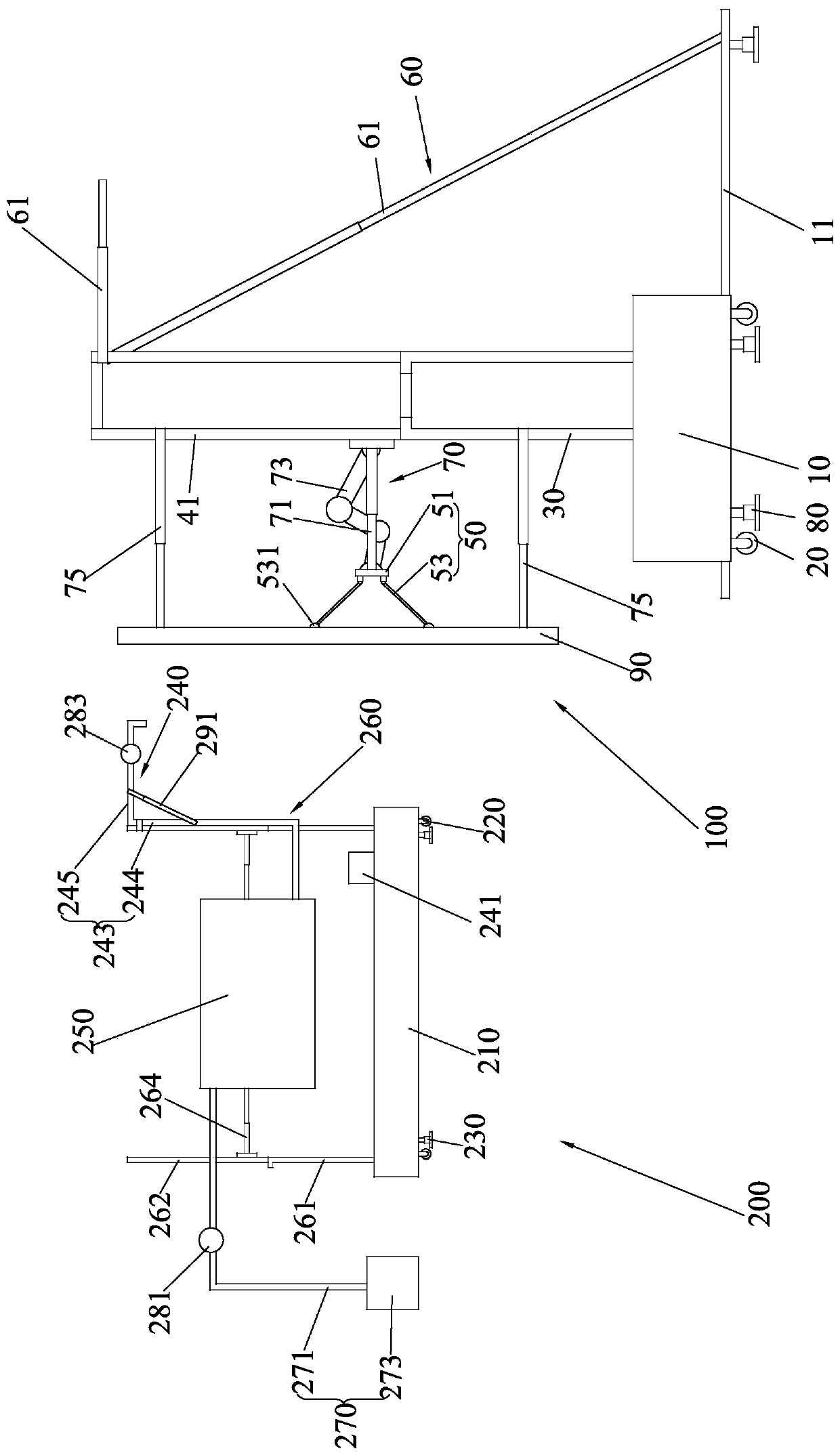

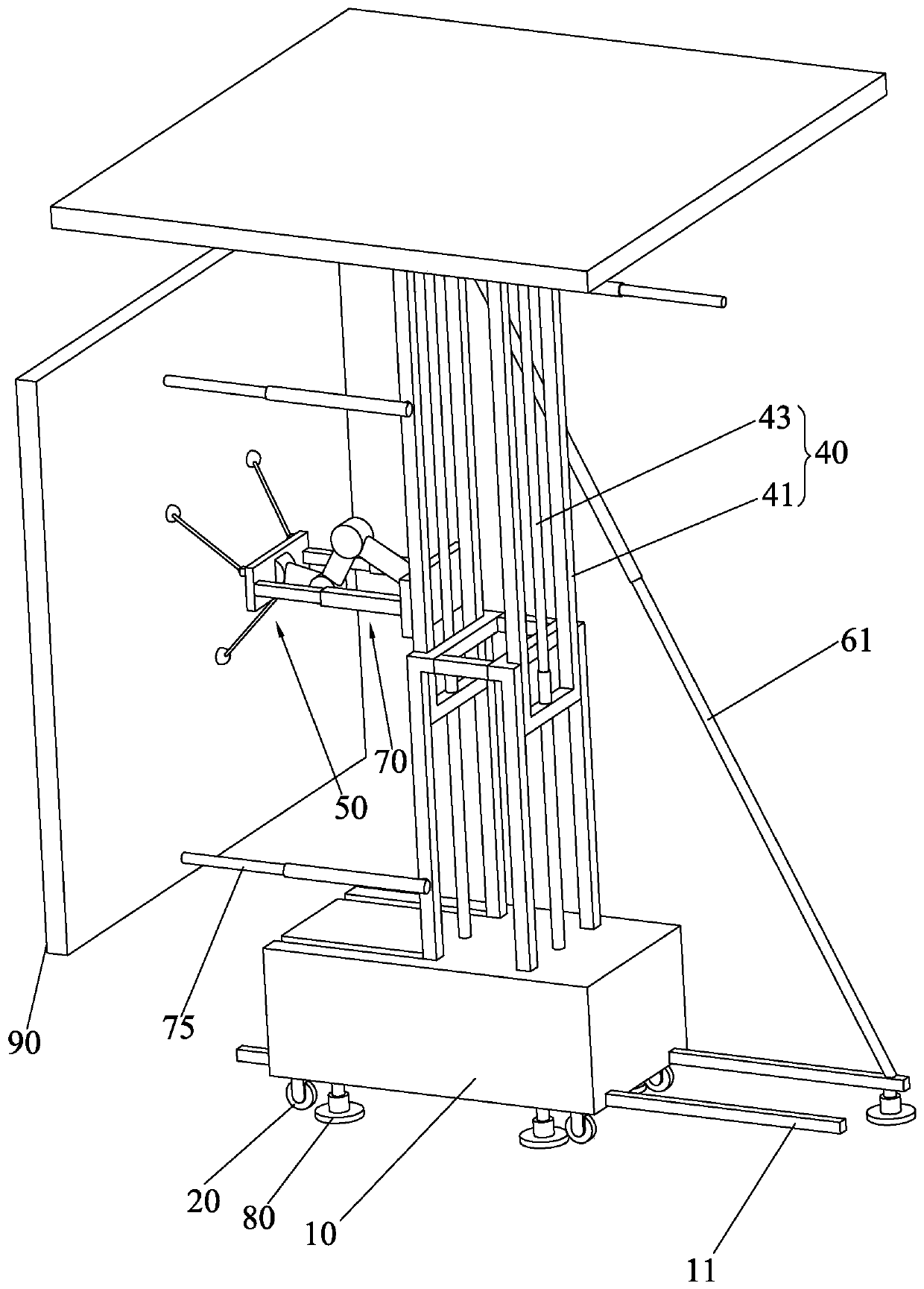

[0036] Such as Figure 1-Figure 2 As shown, the building component forming robot assembly 300 of the present invention includes a building component forming robot 100 and a building 3D printing robot 200. The building component forming robot is used to form a template 90 into a mold cavity, and the building 3D printing robot transports the building gelling material to The mold cavity is poured to complete the building component molding. The building component forming robot 100 includes a base 10, a first walking system 20, a first frame body 30, a lifting system 40, at least one grasping and leveling system 50, at least one auxiliary support system 60, and a first fixing system 80. The first walking The system 20 and the first fixing system 80 are arranged at the bottom of the base 10 , the first frame body 30 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com