Lead screw clamping type metal hard tube rotary cutter

A cutting machine and clamping technology, applied in the field of screw clamping metal hard pipe rotary cutting machines, can solve the problems of unqualified steel pipe quality, radial deformation of steel pipe, flattening of steel pipe ports, etc., and increase the contact area. , to achieve expansion, to ensure reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Further explain the present invention below in conjunction with embodiment and accompanying drawing.

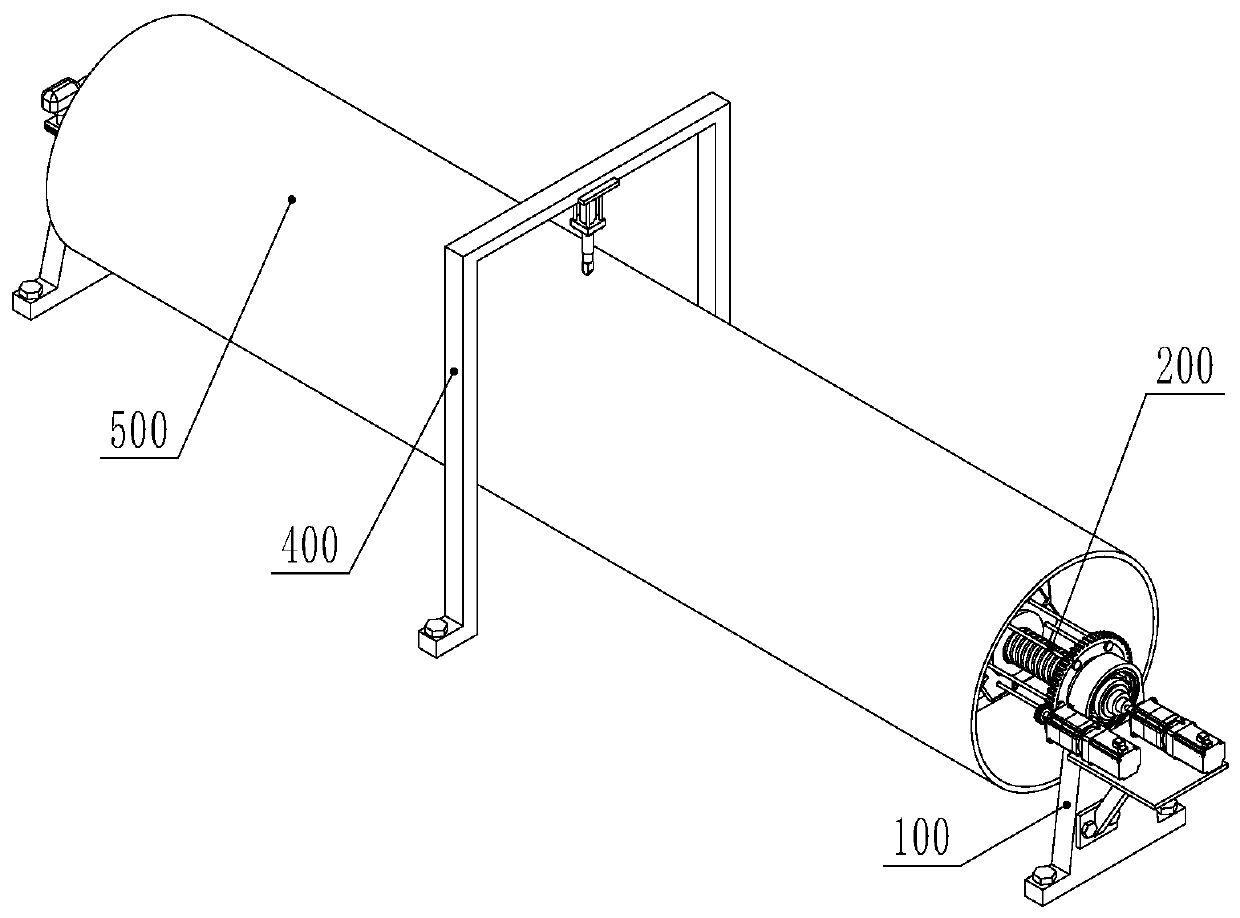

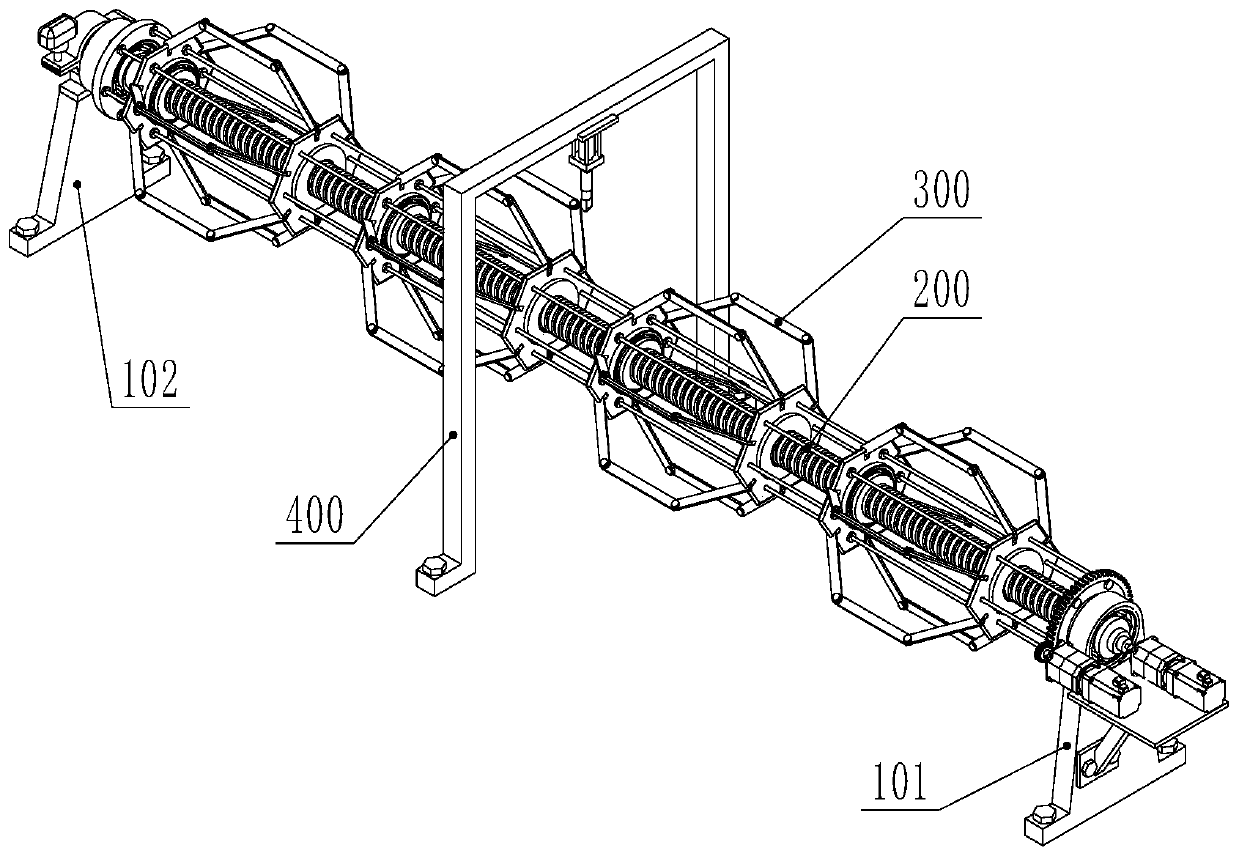

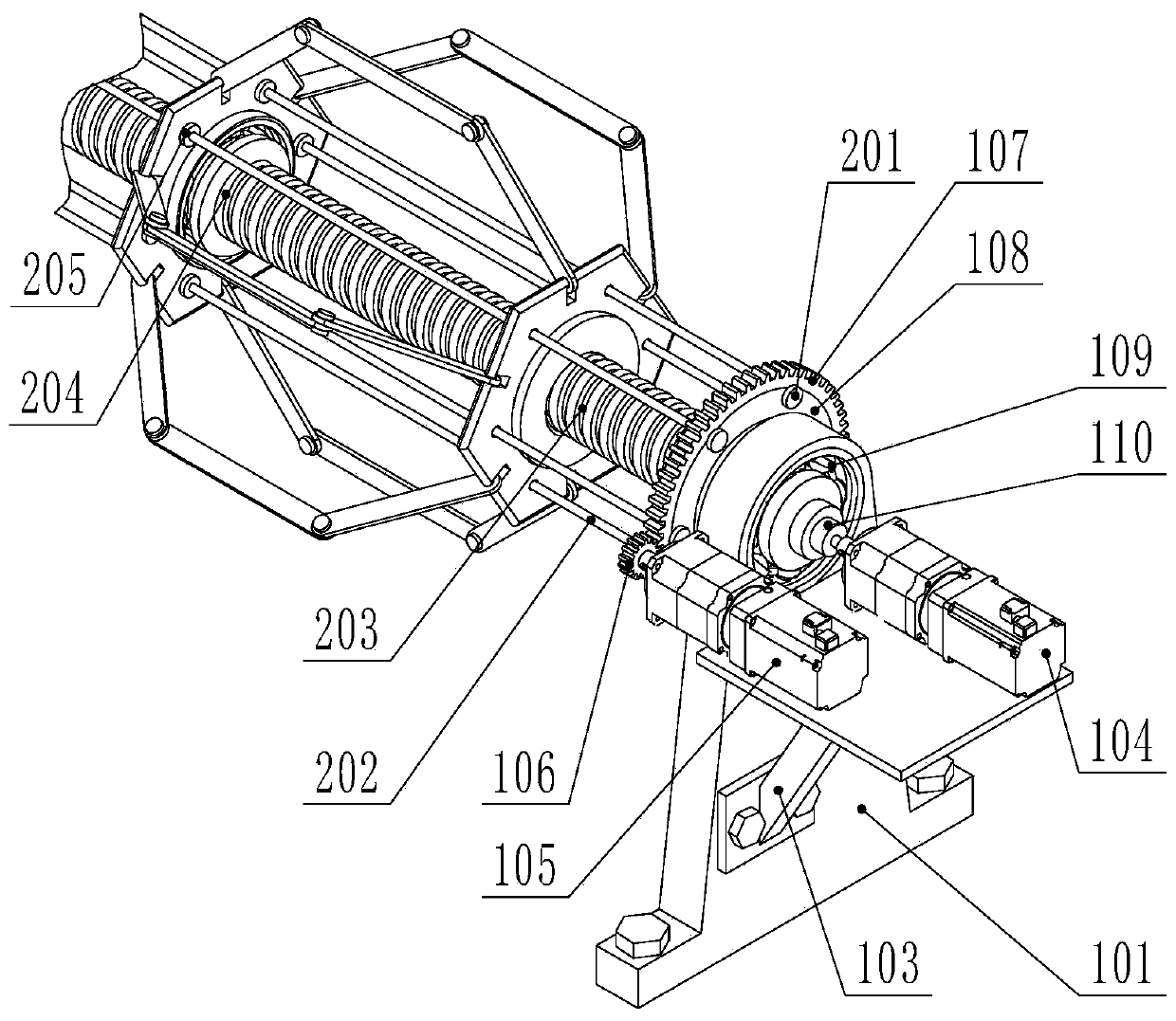

[0033] The present invention is a screw clamping type metal hard tube rotary cutting machine (referred to as cutting machine, see Figure 1-9 ) includes a support device 100, a screw device 200, an expansion device 300 and a cutting device 400. The support device 100 is located at the front and rear ends of the entire cutting machine and is fixed to the ground, which is equivalent to the frame part of the cutting machine; The expansion device 300 is set on the lead screw device 200, and the two devices are connected by threads, and there are four expansion devices 300, which are uniformly arranged before and after, and the metal hard tube 500 to be cut is placed on the expansion device outer cover; the cutting device 400 is located at The screw device 200 is in the middle position, and is also in the middle position in the left-right direction.

[0034] The support d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com