Preparation method of CdIn2S4 nano particle modified few-layer MoS2 nanosheet composite photocatalyst

A nanoparticle, cdin2s4 technology, applied in the field of inorganic nanocomposite materials, achieves the effect of simple operation process, broad application prospects and short reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

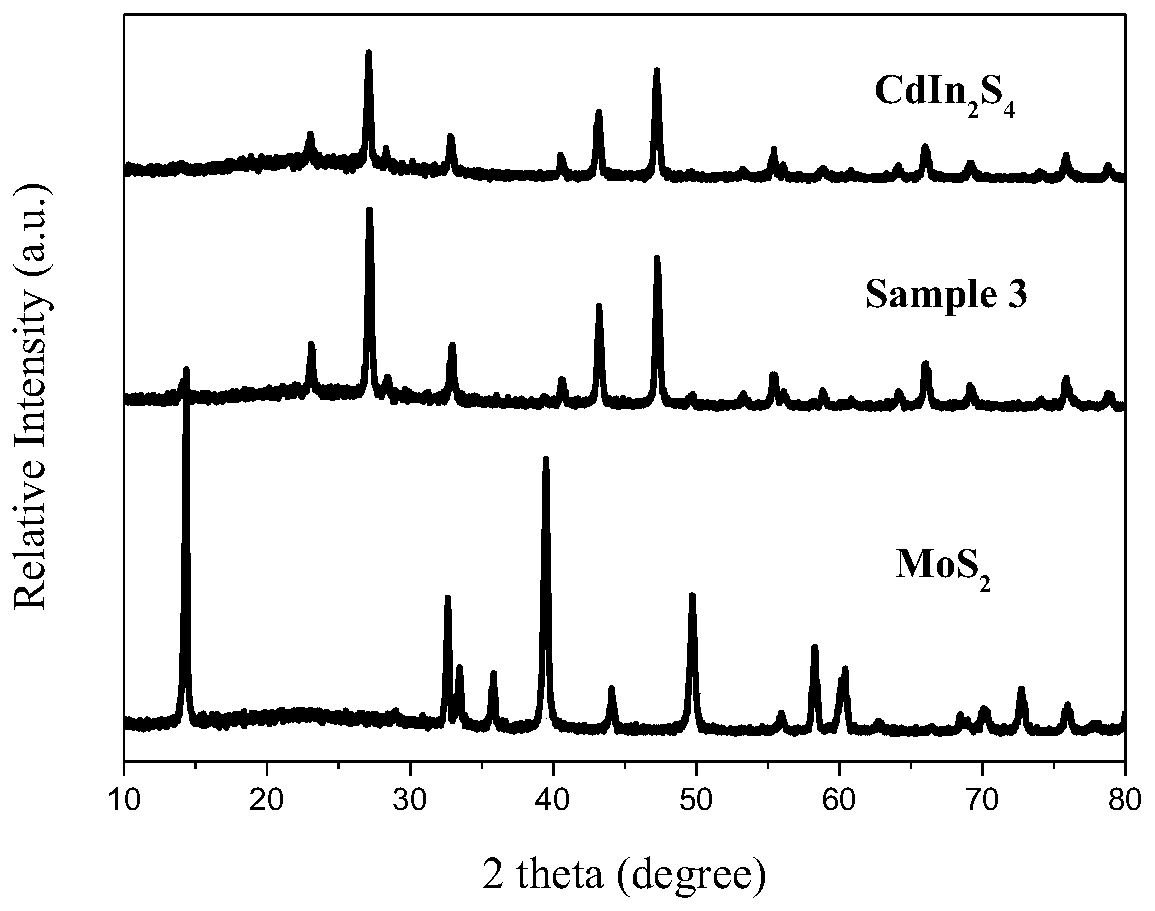

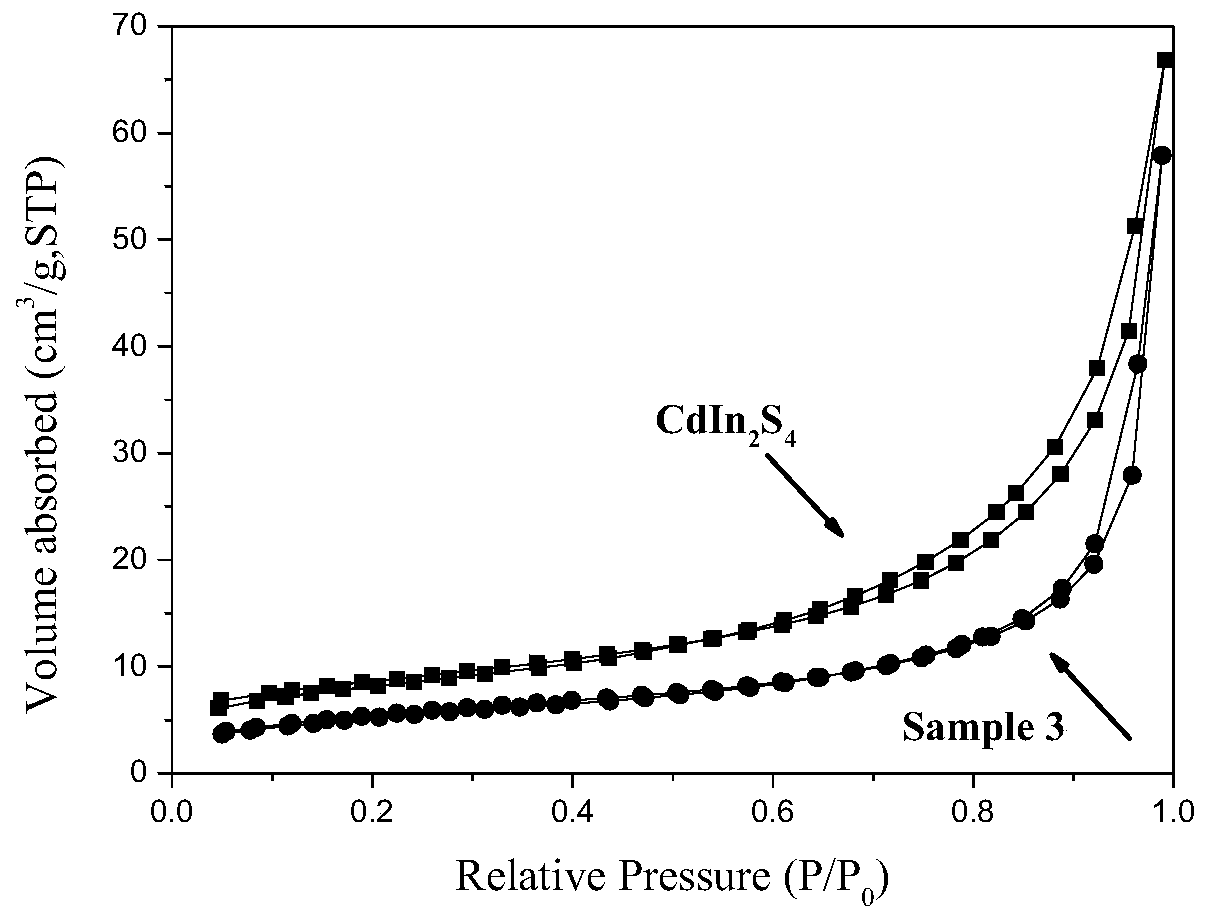

[0024] (1) Weigh 0.0009g MoS 2The nano-blocks were dispersed in 10 ml of ethanol, centrifuged at 2000 r / min after ultrasonication for 8 h, and the upper layer of light black suspension was taken, and then vacuum-dried to obtain a few layers of MoS 2 ultrathin nanosheets.

[0025] (2) MoS in step (1) 2 All ultrathin nanosheets were added to 15mL of absolute ethanol, ultrasonically dispersed for 30min, and then 0.1405g of CdSO was added to it 4 ·8H 2 O, after ultrasonic stirring for 10min, add 0.3044g In(NO 3 ) 3 ·4.5H 2 O and 0.2427g CH 4 N 2 S (thiourea), stir until dissolved, then carry out hydrothermal reaction, the temperature is 180 ° C, the time is 15 h, and it is cooled to room temperature, centrifuged, washed, and dried to obtain CdIn 2 S 4 Nanoparticle-modified few-layer MoS 2 Nanosheet composite photocatalyst. where MoS 2 The mass percentage of the composite photocatalyst is 0.5%

[0026] When the sample was exposed to visible light for 90 min, the photoc...

example 2

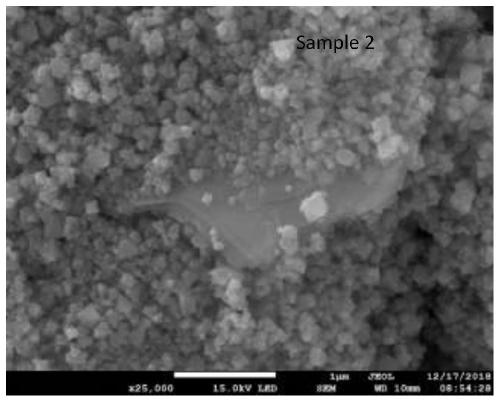

[0029] (1) Weigh 0.0068g MoS 2 The nanoblocks were dispersed in 15ml of ethanol, centrifuged at 2500r / min after ultrasonication for 10h, and the upper layer of light black suspension was taken, and then vacuum-dried to obtain few-layer MoS 2 ultrathin nanosheets.

[0030] (2) MoS in step (1) 2 All the ultrathin nanosheets were added to 20mL of absolute ethanol, ultrasonically dispersed for 30min, and then 0.5339g of CdSO was added to it 4 ·8H 2 O, after ultrasonic stirring for 15min, add 1.1567g In(NO 3 ) 3 ·4.5H 2 O and 0.9223g CH 4 N 2 S (thiourea), stir until dissolved, then carry out a hydrothermal reaction, the temperature is 190 ° C, the time is 18 h, and it is cooled to room temperature, centrifuged, washed, and dried to obtain CdIn 2 S 4 Nanoparticle-modified few-layer MoS 2 Nanosheet composite photocatalyst. where MoS 2 The mass percentage of the composite photocatalyst is 1%

[0031] When the sample was exposed to visible light for 90 min, the photocatal...

example 3

[0035] (1) Weigh 0.0236g MoS 2 The nano-blocks were dispersed in 20 ml of ethanol, centrifuged at 2500 r / min after ultrasonication for 12 h, and the upper layer of light black suspension was taken, and then vacuum-dried to obtain a few layers of MoS 2 ultrathin nanosheets.

[0036] (2) MoS in step (1) 2 All the ultrathin nanosheets were added to 25mL of absolute ethanol, ultrasonically dispersed for 40min, and then 0.8711g of CdSO was added to it 4 ·8H 2 O, after ultrasonic stirring for 20min, add 1.8873g In(NO 3 ) 3 ·4.5H 2 O and 1.5047g CH 4 N 2 S (thiourea), stir to dissolve, then carry out hydrothermal reaction, temperature 200 ℃, time 20h, let it cool to room temperature, centrifuge, wash and dry to obtain CdIn 2 S 4 Nanoparticle-modified few-layer MoS 2 Nanosheet composite photocatalyst. where MoS 2 The mass percentage of the composite photocatalyst is 2%

[0037] When the sample was exposed to visible light for 90 min, the photocatalytic degradation efficie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com