Infusion port injection holder fixing device

A technology of a fixing device and an injection seat, which is applied in the field of medical devices, can solve the problems that the infusion needle cannot be connected, and cannot ensure the smooth insertion of the infusion needle, etc., and achieves the effects of improving the comfort of use, good practicability, and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

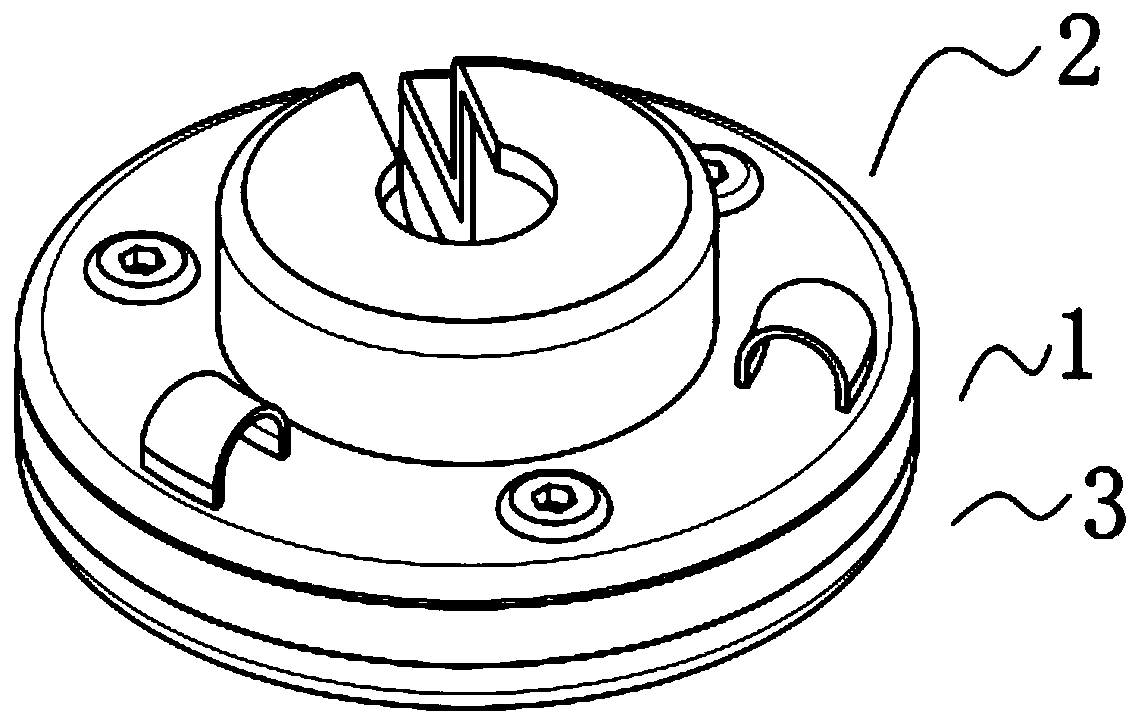

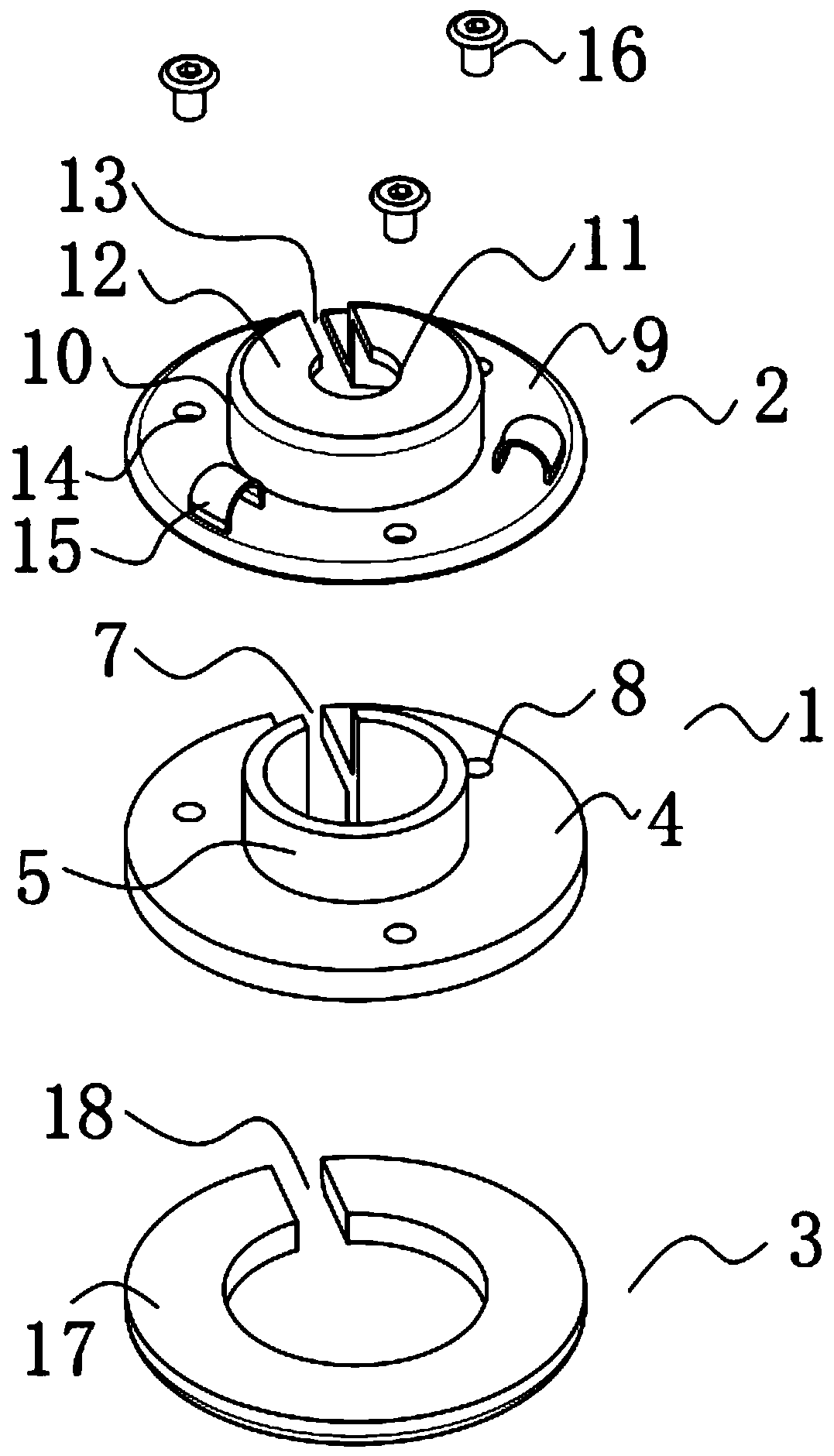

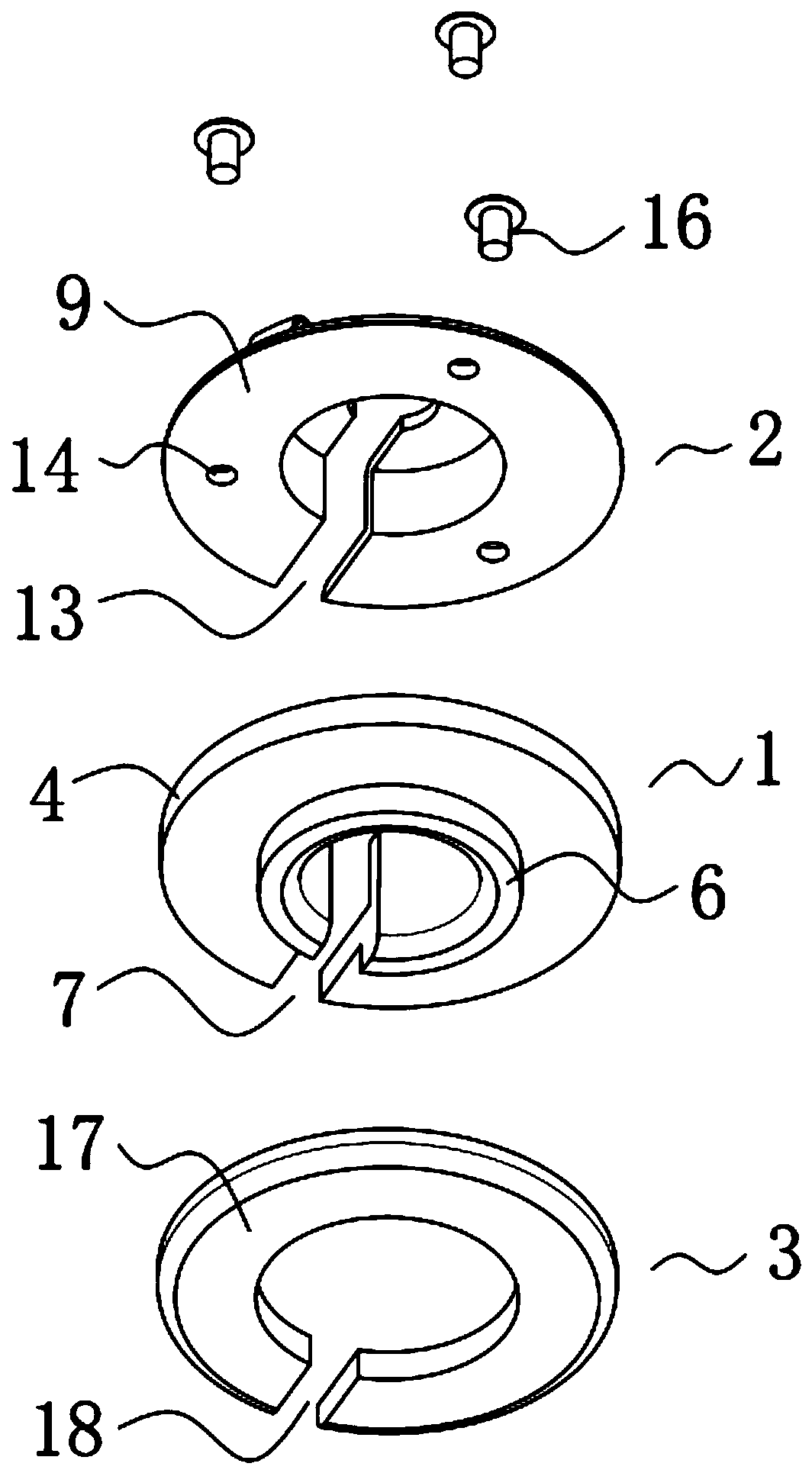

[0053] An infusion port injection seat fixing device, such as figure 1 As shown, it includes a main structure 1, a limiting structure 2 and a protective structure 3, the limiting structure 2 is installed on the upper part of the main structure 1, and the protective structure 3 is installed on the bottom of the main structure 1;

[0054] like Figure 2-4 As shown in and 6, the main structure 1 includes a circular fixing plate 4, an upper bezel 5, a lower bezel 6, and a hole that passes through the circular fixing plate 4, the upper bezel 5, and the lower bezel 6. The first gap 7, the upper flange 5 is integrally arranged at the upper center of the circular fixing plate 4, the lower flange 6 is integrally arranged at the bottom center of the circular fixing plate 4, and The interior of the lower bead 6 and the interior of the upper bezel 5 are arranged to communicate with each other;

[0055] like Figure 2-4 As shown in and 6, the limiting structure 2 includes an annular mou...

Embodiment 2

[0084] The difference with embodiment 1 is the preparation of annular silicone ring 17, and its specific preparation method is as follows:

[0085] Take the following raw materials and weigh them by weight: 50 parts of methyl vinyl phenyl silicone rubber, 10 parts of polyurethane, 17 parts of zinc oxide powder, 18 parts of nano-silver powder, 4 parts of p-phenylenediamine, diethyl sulfide 5 parts of urea, 5 parts of paraffin oil, 3 parts of tricresyl phosphate;

[0086] S1. Add the weighed methyl vinyl phenyl silicone rubber and polyurethane into a pulverizer for pulverization, and set the speed of the pulverizer to 700r / min to obtain a pulverized mixed material;

[0087] S2. Put the pulverized mixed material prepared in step S1 into a banbury mixer for banburying, set the temperature of the banbury mixer to 160° C., set the speed to 700 r / min, and banbury the time for 25 minutes to obtain banbury materials ;

[0088] S3. Add the banburying materials prepared in step S2, zin...

Embodiment 3

[0092] The difference with embodiment 1 is the preparation of annular silicone ring 17, and its specific preparation method is as follows:

[0093] Take the following raw materials and weigh them by weight: 60 parts of methyl vinyl phenyl silicone rubber, 12 parts of polyurethane, 18 parts of zinc oxide powder, 20 parts of nano-silver powder, 5 parts of p-phenylenediamine, diethyl sulfide 6 parts of urea, 6 parts of paraffin oil, 4 parts of tricresyl phosphate;

[0094] S1. Put the weighed methyl vinyl phenyl silicone rubber and polyurethane into a pulverizer for pulverization, and set the speed of the pulverizer to 800r / min to obtain a pulverized mixed material;

[0095] S2. Put the pulverized mixed material prepared in step S1 into a banbury mixer for banburying. Set the temperature of the banbury mixer to 170° C., the speed to 800 r / min, and the banburying time to 30 minutes to obtain banbury materials ;

[0096] S3. Add the banburying materials prepared in step S2, zinc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com