Segmented beam pier top cast-in-situ movable framework

A technology for moving formwork and segmental beams, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., and can solve problems such as low construction efficiency, high site requirements, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

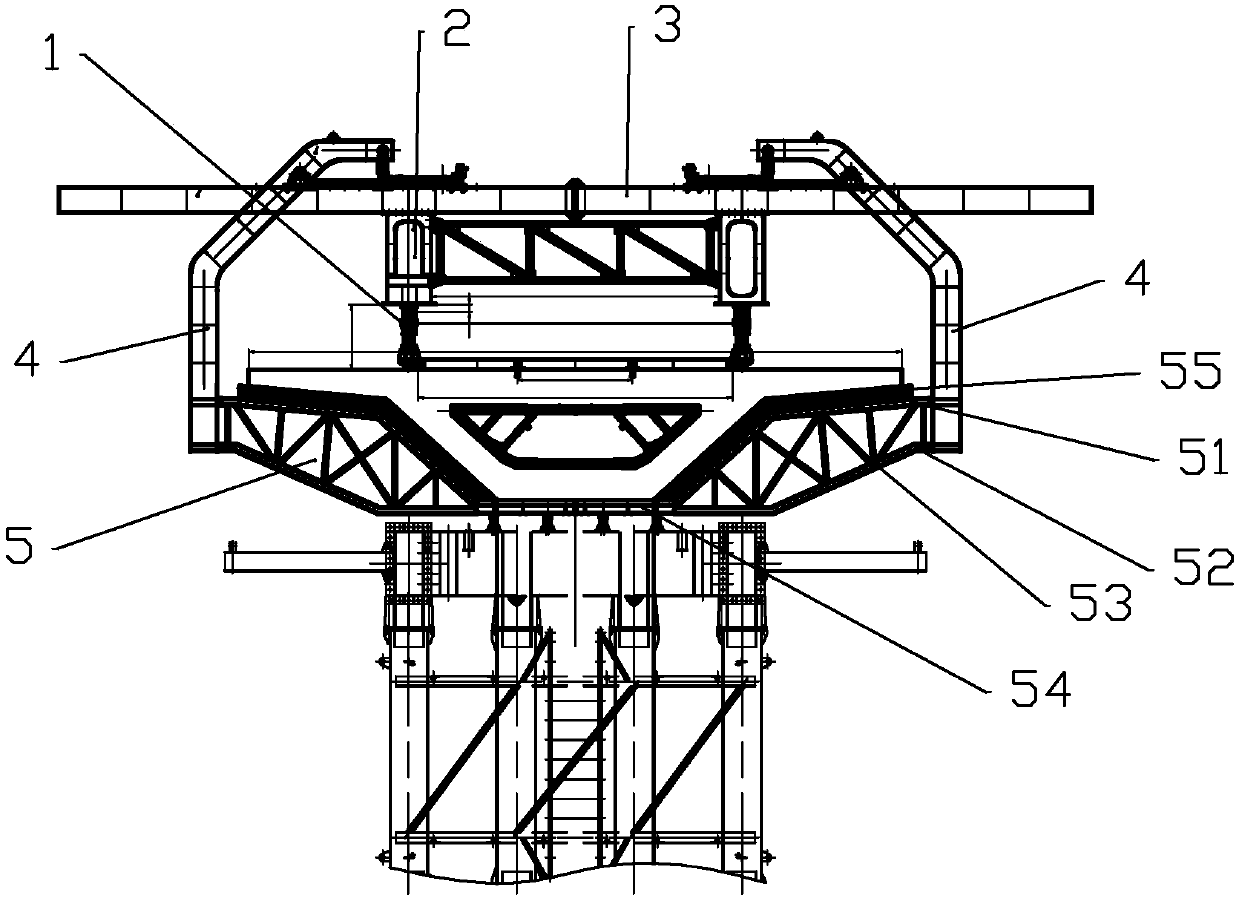

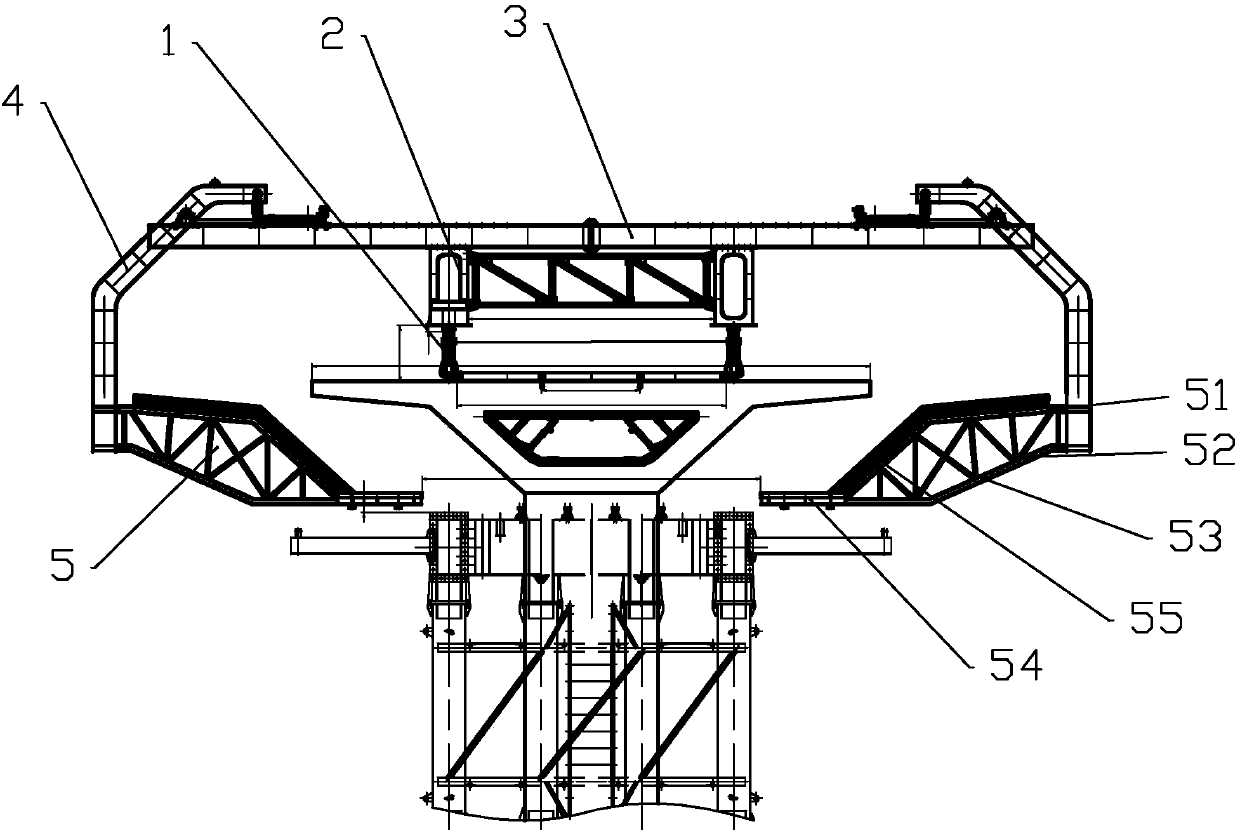

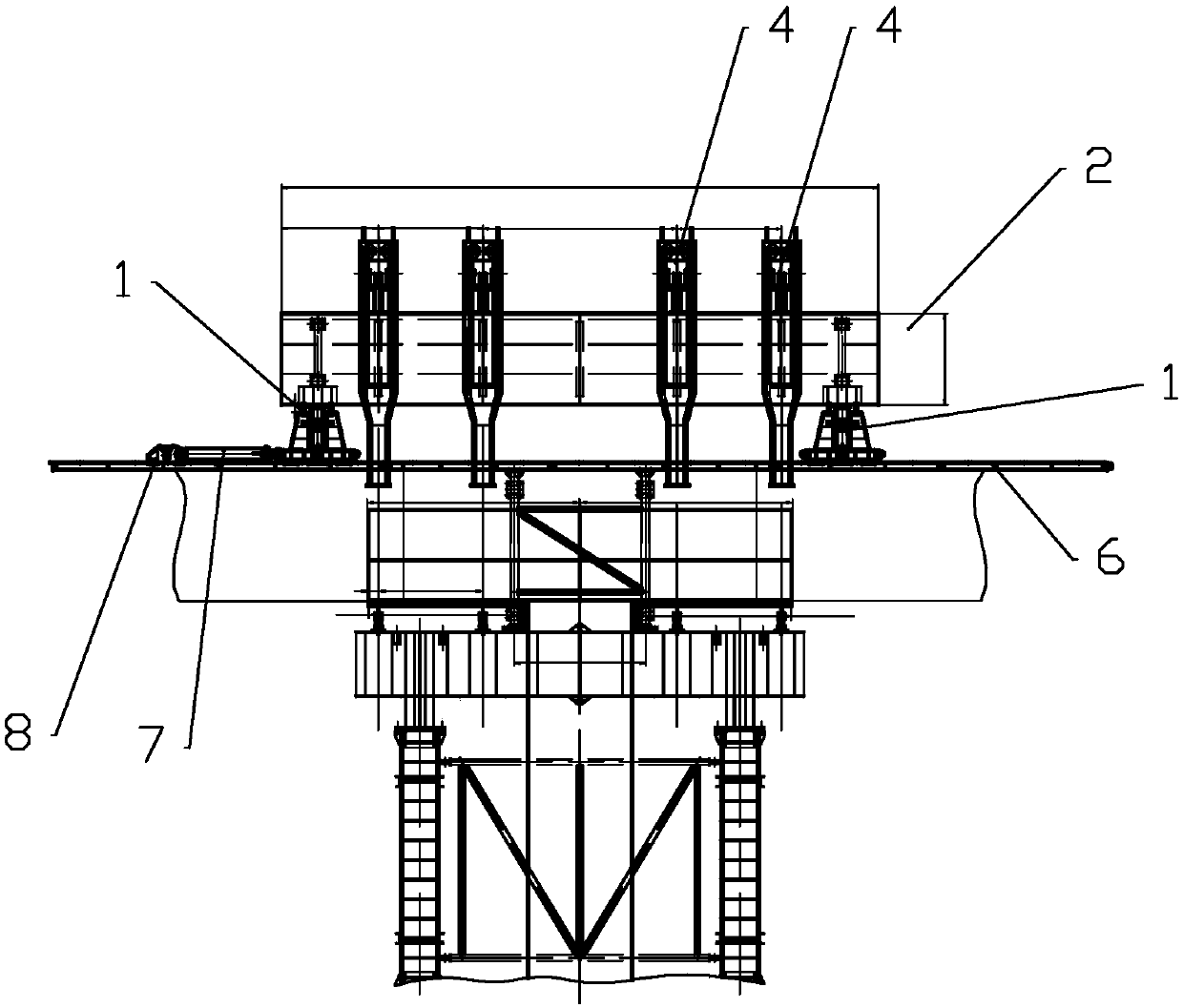

[0023] refer to Figure 1 to Figure 5 , the present invention is a cast-in-place mobile formwork for the top of a segmental beam pier, comprising a number of supporting columns 1 arranged on the top surface of a prefabricated segmental beam that has been constructed, and a plurality of supporting columns 1 jointly supporting the main beam 2, the main The beam 2 is a pair of steel box girders, which are used as the main load-bearing beam of the cast-in-place mobile formwork on the top of the entire segmental beam pier. There are also several upper beams 3 horizontally erected on the main beam 2. The middle parts of each upper beam 3 are connected to the The main beam 2 is connected, and the two ends of each upper beam 3 are suspended and symmetrically provided with lower hanging beams 4 that can slide along the length direction of the upper beam 3. The upper ends of each lower hanging beam 4 are connected with the corresponding upper beam 3. The lower end of the beam 4 is suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com