Coiled bar reinforcing steel bar rotating frame

A technology of rotating frame and steel bar is applied in the field of steel structure rotating support, which can solve the problems of affecting the speed of steel wire coiling, increase in production cost, low resource utilization rate, etc., so as to improve construction efficiency, low production cost, and turnover times many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

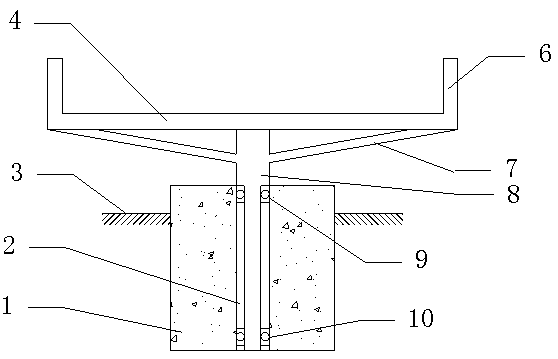

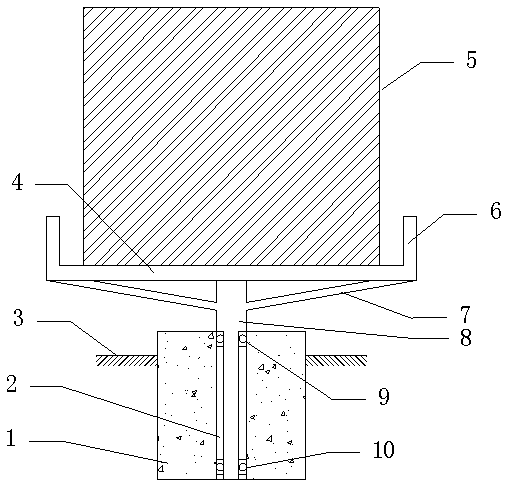

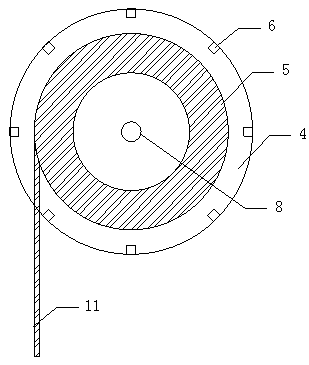

[0025] The round steel bar rotating frame of the present invention includes a pre-embedded pipe and a rotating unit.

[0026] see now figure 1 , figure 1 It is a structural schematic diagram of a round steel bar rotating frame according to an embodiment of the present invention. As shown in the figure, the embedded pipe 2 is a steel pipe vertically fixed into the foundation. The first bearing 9 is fixed in the upper port of the embedded pipe, and the second bearing 10 is fixed in the lower port. The inner diameters of the two bearings are 50mm, with an outer diameter of 70mm and a height of 14mm. The outer side of the bearing is welded to both ends of the embedded pipe with a diameter of 70mm. The inner side of the first bearing 9 is welded with the embedded pipe, and the second bearing 10 is closely attached to the arc shape of the lower part of the embedded pipe. The upper port of the embedded pipe is exposed to the ground for 3100mm; the size of the foundation is 600mm*...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com