Method for preparing difunctional composite catalyst of light aromatics from benzene and synthesis gas in one step

A technology of composite catalyst and light aromatics, which is applied in the field of coal chemical industry, can solve the problems of low benzene conversion rate, no efficient coupling of active sites, low conversion rate, etc., achieve high selectivity, inhibit the formation of ethylbenzene, and catalyze Good performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

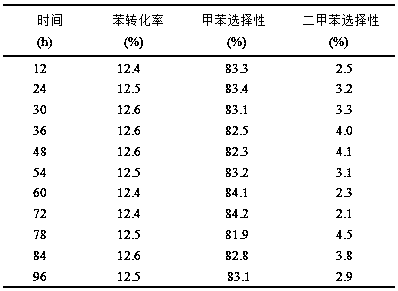

Embodiment 1

[0020] Step 1: Co-precipitation method is used to prepare CuO catalyst: under the condition of heating in a water bath at 70°C, add 0.5 mol / L of Cu(NO 3 ) 2 Add 1mol / L of (NH 4 ) 2 CO 3 solution until the pH is 8.5, stop stirring, age at 70°C for 2h, then filter the liquid with suction, wash, dry the obtained solid at 100°C overnight, and then calcinate at 500°C for 6h to obtain CuO catalyst;

[0021] Step 2, using hydrothermal synthesis to synthesize acidic molecular sieves:

[0022] 1) Dissolve 0.05g of sodium hydroxide and 0.1g of aluminum isopropoxide in an appropriate amount of distilled water, stir continuously until they are completely dissolved, then add 15ml of tetrapropylammonium hydroxide (TPAOH) solution to the above mixture, After stirring at room temperature for 2 h, a clear solution A was obtained;

[0023] 2) Add 10ml of tetraethyl orthosilicate (TEOS) dropwise to solution A, and keep stirring for 5 hours to obtain mixed sol B.

[0024] The above-mention...

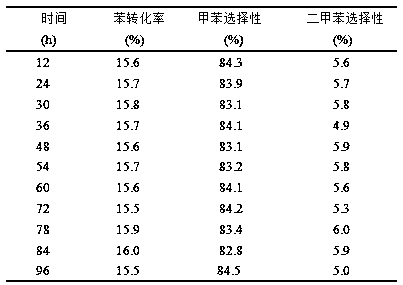

Embodiment 2

[0030] Step 1: Co-precipitation method is used to prepare CuO catalyst: under the condition of heating in a water bath at 70°C, add 0.5 mol / L of Cu(NO 3 ) 2 Add 1mol / L of (NH 4 ) 2 CO 3 solution until the pH is 8.5, stop stirring, age at 70°C for 2h, then filter the liquid with suction, wash, dry the obtained solid at 100°C overnight, and then calcinate at 500°C for 6h to obtain CuO catalyst.

[0031] Step 2. Use hydrothermal synthesis method to synthesize acidic molecular sieve: 1) Dissolve 0.05g sodium hydroxide and 0.2g aluminum isopropoxide in appropriate amount of distilled water, stir continuously until they are completely dissolved, and then add 10ml of tetrapropyl Ammonium hydroxide (TPAOH) solution was added to the above mixture, and stirred at room temperature for 2 hours to obtain a clear solution A.

[0032] 2) Add 10ml of tetraethyl orthosilicate (TEOS) dropwise to solution A, and keep stirring for 5 hours to obtain mixed sol B.

[0033] The above sol B was ...

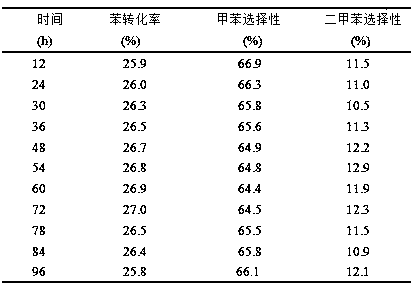

Embodiment 3

[0039]Step 1: Co-precipitation method is used to prepare CuO catalyst: under the condition of heating in a water bath at 70°C, add 0.5 mol / L of Cu(NO 3 ) 2 Add 1mol / L of (NH 4 ) 2 CO 3 Solution, until the pH is 8, stop stirring, age at 70°C for 2h, then filter the liquid with suction, wash, dry the obtained solid at 100°C overnight, and then calcinate at 500°C for 6h to obtain CuO catalyst.

[0040] Step 2. Synthesize acidic molecular sieves by hydrothermal synthesis: 1) Dissolve 0.15g of sodium hydroxide and 0.1g of aluminum isopropoxide in an appropriate amount of distilled water, stir continuously until they are completely dissolved, and then add 15ml of tetrapropyl Ammonium hydroxide (TPAOH) solution was added to the above mixture, and stirred at room temperature for 2 hours to obtain a clear solution A.

[0041] 2) Add 12ml of tetraethyl orthosilicate (TEOS) dropwise to solution A, and keep stirring for 5 hours to obtain mixed sol B.

[0042] The above sol B was tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com