A heat-sensitive anti-malfunction protection device for electric high-voltage equipment array

A technology of high-voltage equipment and protection devices, which is applied in the field of heat-sensitive anti-misoperation protection devices of electric high-voltage equipment arrays, and can solve problems such as inability to perform overheating faults and anti-misoperation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

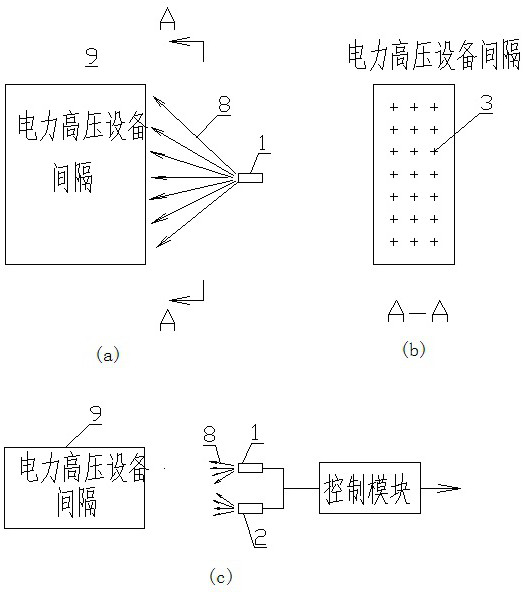

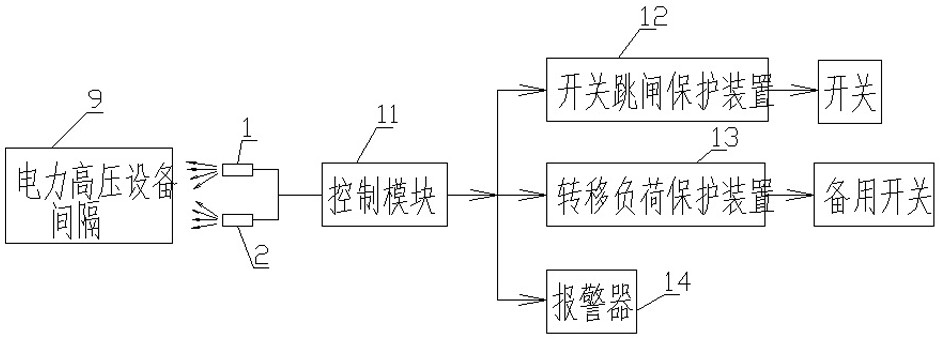

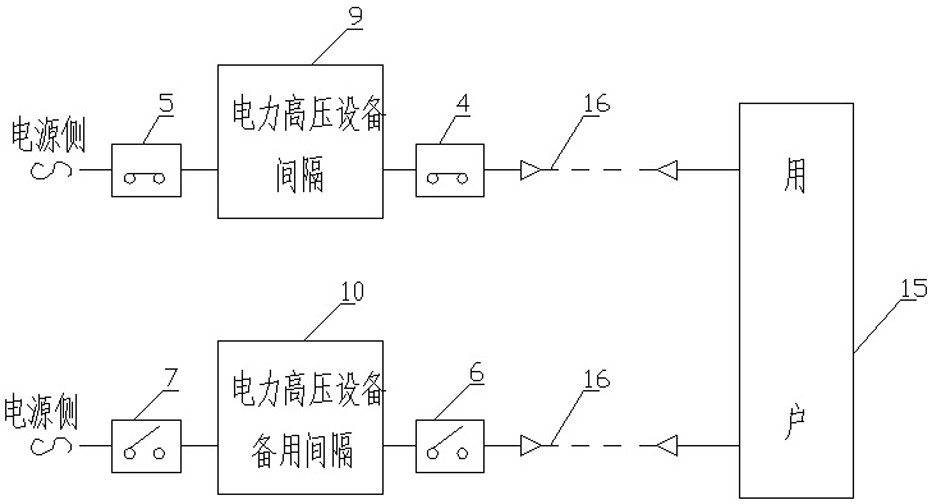

[0014] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0015] The invention provides an array heat-sensitive anti-malfunction protection device for electric high-voltage equipment, including electric high-voltage equipment, a first array of infrared heat-sensitive probes, a second array of infrared heat-sensitive probes, an alarm device, a transfer load protection device, and a switch trip protection device , a control module; the power high-voltage equipment includes a power high-voltage equipment interval, a first power supply side switch, a first user side switch, a power high voltage equipment backup interval, a second power supply side switch, and a second user side switch; the first array The infrared thermistor and the second array of infrared thermistors are connected in parallel to conduct thermal detection on the intervals of high-voltage electric equipment, and transmit the thermal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com